Spring rolls dünya çapında en sevilen atıştırmalıklardan biridir, gevrek dokuları ve lezzetli dolguları nedeniyle beğenildi. Restoranlar için, catering işletmeleri, ve gıda üreticileri, tutarlı üretmek, yüksek kaliteli yaylı rulo sarmalayıcılar manuel olarak yapıldığında zorlu bir iştir. İşte burada Bahar rulo sarma makinesi gerekli hale gelir. Bu gelişmiş gıda işleme ekipmanı, ambalaj üretimini otomatikleştiriyor, Verimliliği sağlamak, hijyen, ve maliyet etkinliği.

Bilmeniz gereken her şeyi derinlemesine inceleyeceğiz bahar rulo makineleri—onların özellikleri, faydalar, çalışma prensibi, Teknik Özellikler, ve gıda işinizi nasıl dönüştürebileceklerini.

Spring Roll Sarma Makinesi Nedir??

A bahar rulo sarma makinesi ince ürünler üretmek üzere tasarlanmış bir gıda işleme makinesidir., yuvarlak, ve düzgün pasta tabakaları (sarmalayıcılar) Çin böreği yapmak için kullanılır, samosalar, köfte, ve diğer benzer atıştırmalıklar. Geleneksel olarak, Bu sarmalayıcıları elle yapmak beceri gerektirir, zaman, ve tutarlılık. Bir makine süreci otomatikleştirir, Minimum işçilikle yüksek hacimli üretime olanak tanır.

Makine yaygın olarak kullanılmaktadır:

- Gıda işleme fabrikaları

- Dondurulmuş gıda tedarikçileri

- Yoğun talep gören otel ve restoranlar

- Catering işletmeleri

Bu makine ile, İşletmeler, kalite standartlarını korurken artan tüketici talebini karşılayabilir.

Neden Spring Roll Wrapper Yapma Makinesine Yatırım Yapmalısınız??

Bir satın alma bahar rulo sarma makinesi bir ekipman yükseltmesinden daha fazlasıdır; verimlilik ve ölçeklenebilirliğe yapılan bir yatırımdır. İşte gıda işletmelerinin geçiş yapmasının bazı nedenleri:

- Kalitede Tutarlılık

El yapımı ambalajların kalınlığı ve boyutu genellikle farklılık gösterir, nihai ürünü etkileyebilecek. Bir makine tekdüzeliği garanti eder. - Yüksek üretim kapasitesi

Modele bağlı olarak, makineler saatte yüzlerce ila binlerce ambalaj kağıdı üretebilir. - İşgücü Maliyet Tasarrufu

Manuel ambalaj üretimi emek yoğundur. Bir makine ekstra personel ihtiyacını azaltır. - Hijyen ve Gıda Güvenliği

Makine doğrudan el temasını en aza indirir, Gıda güvenliği mevzuatına uygunluğun sağlanması. - Çok yönlülük

Çin böreği dışında, makine samosa tabakaları üretebilir, lumpia sarmalayıcılar, hamur tatlısı derileri, ve hatta krepler.

Spring Roll Sarma Makinesi Nasıl Çalışır??

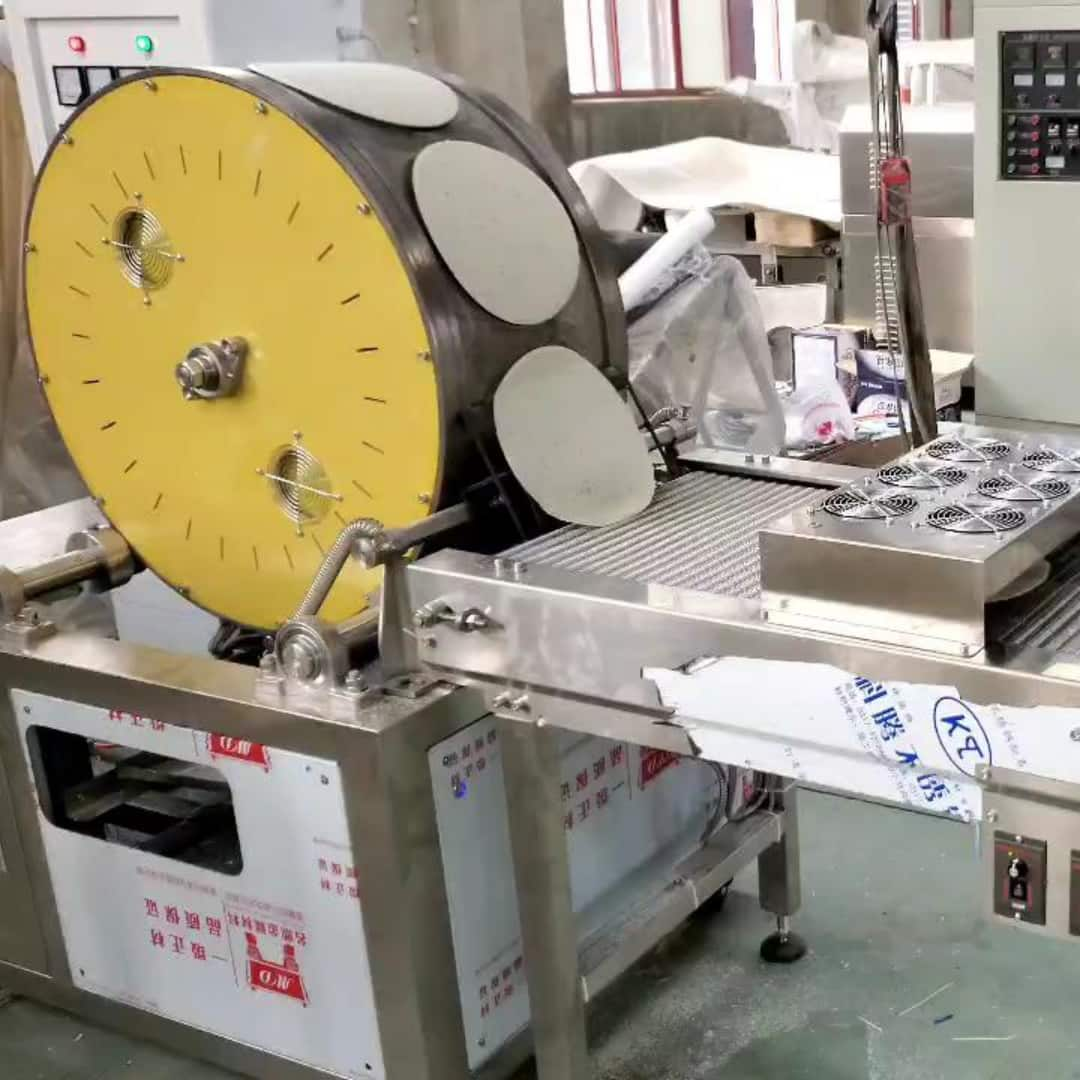

Anlamak yaylı rulo sarma makinesinin çalışma prensibi işletmelerin verimli bir şekilde çalışmasına yardımcı olur.

- Hamur hazırlığı

Un, su, ve bazen nişasta pürüzsüz bir karışım oluşturacak şekilde karıştırılır, topaksız hamur. - Otomatik Besleme Sistemi

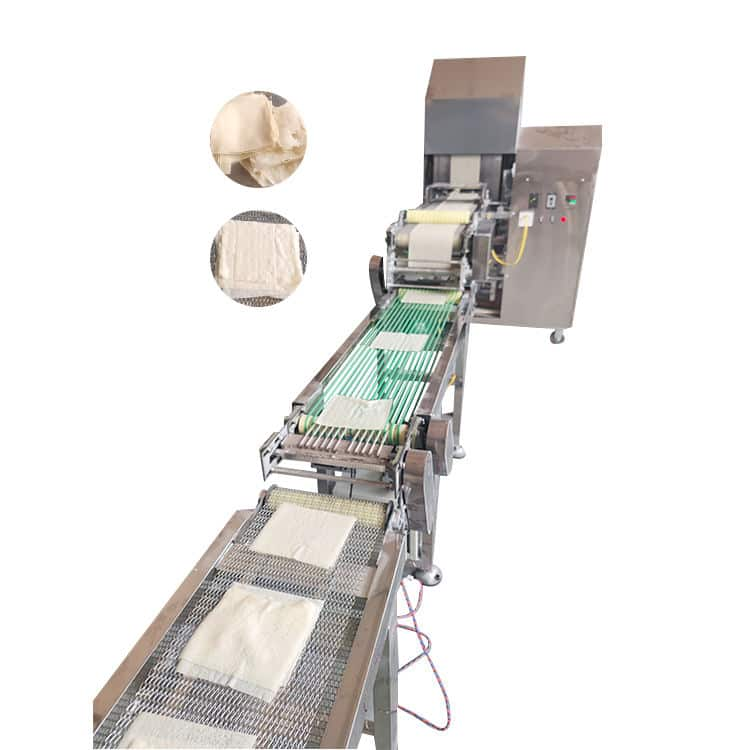

Hamur makinenin yayma sistemine pompalanır. - Isıtma & Pişirme

Hamur, ısıtılmış dönen bir tambur veya plaka üzerine eşit şekilde yayılır.. Saniyeler içinde, ince pişmiş bir tabaka oluşturur. - Kesme & Şekillendirme

Sayfa otomatik olarak istenen şekillerde kesilir (yuvarlak), kare, veya dikdörtgen — üretim ihtiyaçlarına bağlı olarak. - İstifleme & Sayma

Bitmiş ambalajlar otomatik olarak istiflenir ve sayılır, ambalajlamaya veya hemen kullanıma hazır.

Otomatik Spring Roll Sarma Makinesinin Temel Özellikleri

Modern otomatik yaylı rulo sarma makineleri Kullanıcı dostu çalışma ve maksimum çıktı sağlayan ileri teknolojiyle birlikte gelir. Bazı özellikler şunları içerir::

- Paslanmaz Çelik Konstrüksiyon (gıda sınıfı, paslanmaya dayanıklı, temizlenmesi kolay)

- Ayarlanabilir Sarma Kalınlığı (genellikle 0,3 mm–1,2 mm)

- Çoklu Şekil Seçenekleri (yuvarlak, kare, dikdörtgen)

- Sıcaklık Kontrol Sistemi (Eşit pişirme için hassas ısıtma)

- Otomatik Kesim & İstifleme

- Enerji verimliliği (optimize edilmiş ısıtma sistemi güç tüketimini azaltır)

Spring Roll Sarma Makinesi Teknik Parametreleri

Aşağıda genel bir teknik parametre tablosu ticari bir yaylı rulo sarma makinesi için:

| Model | Kapasite (adet/saat) | Paketleyici Boyutu (mm) | Sarma Kalınlığı (mm) | Güç (KW) | Boyutlar (mm) | Ağırlık (kilogram) |

|---|---|---|---|---|---|---|

| SRW-300 | 3000 | 100–200 | 0.3–1.0 | 6.5 | 1200×800×1300 | 350 |

| SRW-600 | 6000 | 100–220 | 0.3–1.2 | 9.0 | 1500×1000×1500 | 500 |

| SRW-1000 | 10,000 | 100–250 | 0.3–1.2 | 12.5 | 1800×1200×1600 | 750 |

Not: Teknik özellikler üreticiye ve özelleştirme ihtiyaçlarına bağlı olarak değişiklik gösterebilir.

Spring Roll Sarma Makinası Çeşitleri

Üretim ölçeğine ve iş gereksinimlerine bağlı olarak farklı modeller mevcuttur:

1. Küçük Ölçekli Spring Roll Sarma Makinası

Restoranlar için ideal, küçük yemek hizmetleri, veya yeni başlayanlar. Kompakt, kullanımı kolay, ve uygun fiyatlı.

2. Yarı Otomatik Bahar Rulo Sarma Makinesi

Bazı adımlarda manuel yardım gerektirir, orta ölçekli üretime uygun.

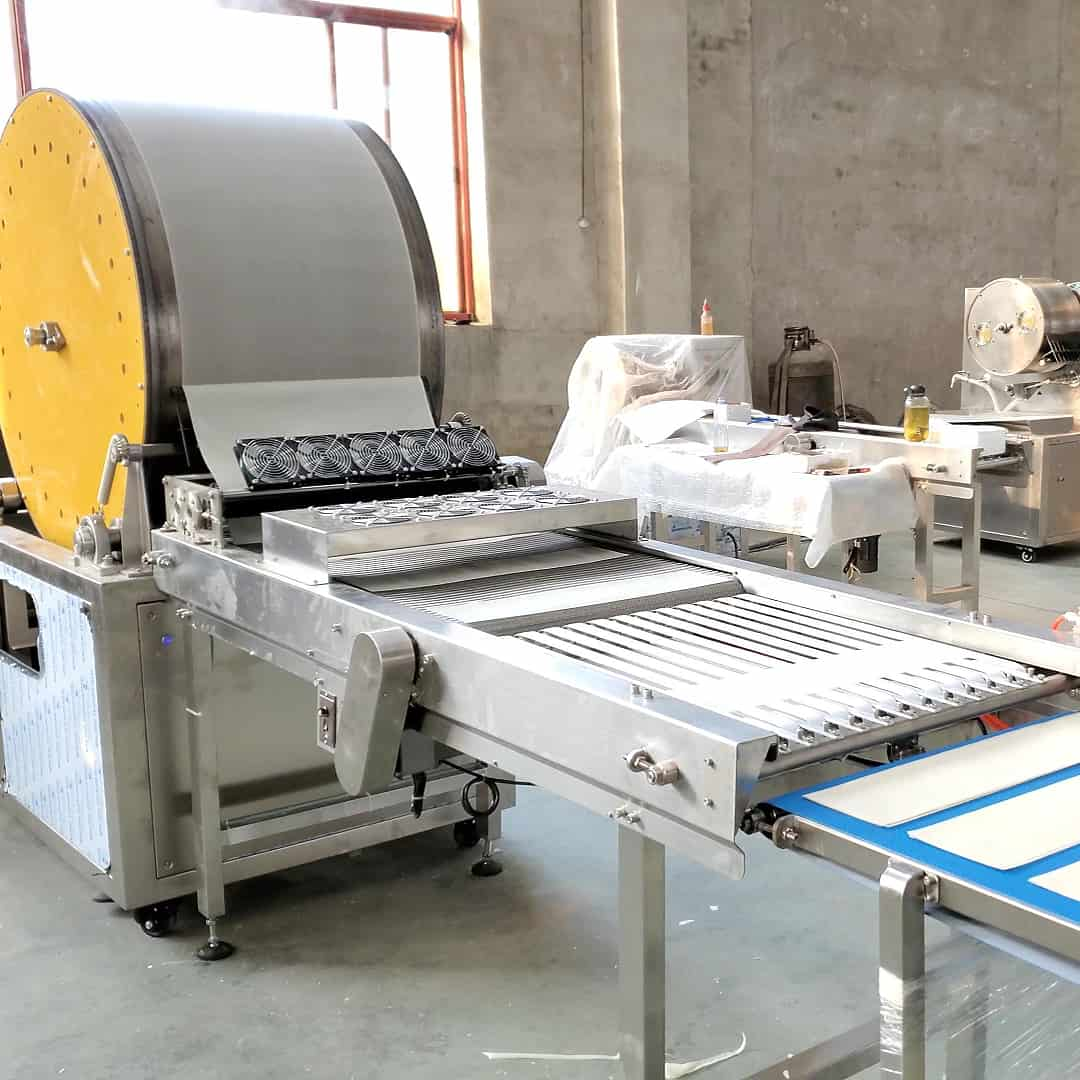

3. Tam Otomatik Spring Roll Sarma Makinesi

Tüm süreci yönetir; besleme, pişirme, kesme, ve istifleme — yüksek üretim talebi olan gıda fabrikaları için ideal.

Tam Otomatik Spring Roll Sarma Makinasının Avantajları

- Tek Kişilik Operasyon – Minimum personel ile yönetimi kolay.

- Yüksek Hız & Yeterlik – Saatte binlerce ambalaj üretebilir.

- Özelleştirme Seçenekleri – Ayarlanabilir boyut, kalınlık, ve şekil.

- Dayanıklılık – Paslanmaz çelik gövde ile uzun ömürlü.

- Yatırım Getirisi – İşgücü tasarrufu ve daha yüksek üretim sayesinde daha hızlı geri ödeme.

Spring Roll Wrapper Yapma Makinesi Uygulamaları

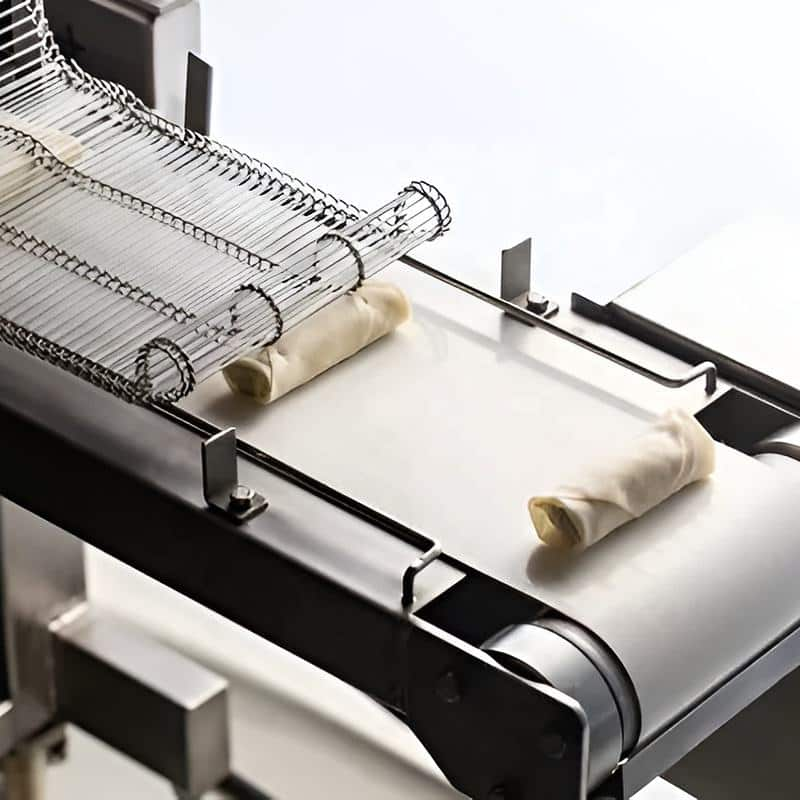

Çin böreği dışında, . sarma makinesi ayrıca üretebilir:

- Samosa Çarşafları

- Lumpia Paketleyiciler

- Hamur tatlısı derileri

- Wonton Paketleyiciler

- Krep veya Krep

Bu çok yönlülük, onu dondurulmuş gıda ve atıştırmalık endüstrisindeki işletmelerin vazgeçilmezi haline getiriyor.

Spring Roll Sarma Makinesi Fiyatı: Dikkate alınması gereken faktörler

. yaylı rulo sarma makinesi fiyatı çeşitli faktörlere bağlıdır:

- Üretim kapasitesi – Daha yüksek kapasiteli makineler daha pahalıdır.

- Otomasyon seviyesi – Tam otomatik modeller yarı otomatik olanlara göre daha maliyetlidir.

- Malzeme & Kalite Oluşturun – Paslanmaz çelik yapı hem dayanıklılığı hem de maliyeti artırır.

- Özelleştirme Seçenekleri – Özel şekiller, boyutlar, veya işlevler fiyatlandırmayı etkiler.

Ortalamada, küçük modeller yaklaşık maliyete mal olabilir $3,000- 8.000 dolar, tam otomatik büyük ölçekli makineler ise $15,000-50.000$ spesifikasyonlara bağlı olarak.

En İyi Spring Roll Sarma Makinesi Nasıl Seçilir

Bir seçim yaparken Spring Roll pasta levha makinesi, aşağıdakileri göz önünde bulundurun:

- Üretim İhtiyaçları - Küçük, orta, veya endüstriyel kapasite.

- Alan Kullanılabilirliği – Makinenin üretim alanınıza uygun olduğundan emin olun.

- Kullanım Kolaylığı – Kullanıcı dostu kontrolleri arayın.

- Satış sonrası hizmet – Güvenilir tedarikçiler kurulum sağlar, eğitim, ve bakım desteği.

- Enerji verimliliği – Gelişmiş ısıtma sistemleriyle elektrik maliyetlerinden tasarruf edin.

Kurulum ve Bakım İpuçları

- Makineyi düz bir yere yerleştirin, kararlı yüzey.

- Spesifikasyonlara göre uygun elektrik bağlantılarını sağlayın.

- Her üretim vardiyasından sonra makineyi iyice temizleyin.

- Isıtma plakalarını ve konveyör bantlarını aşınma açısından düzenli olarak kontrol edin.

- Hareketli parçaları üreticinin önerdiği şekilde yağlayın.

Uygun özenle, A bahar rulo sarma makinesi 8-10 yıl veya daha fazla sürebilir.

Gıda Fabrikaları için Spring Roll Sarma Makinesi

Toplu olarak dondurulmuş atıştırmalıklar üreten gıda fabrikaları, tam otomatik yaylı rulo sarma makinesi. Dondurmayla birlikte, ambalajlama, ve kapatma makineleri, bir oluşturabilir komple Çin böreği üretim hattı, maliyetleri azaltmak ve çıktı verimliliğini artırmak.

Spring Roll Sarıcı Üretim Hattı

Büyük ölçekli üreticiler için, A Bahar rulo sarıcı üretim hattı içerebilir:

- Hamur Karıştırma Makinası

- Otomatik Sarma Makinası

- Dolum Makinası (otomatik yaylı rulo yapımı için isteğe bağlı)

- Kızartma veya Dondurma Makinesi

- Ambalaj makinesi

Bu entegre hat, işletmelerin günde binlerce Çin böreğine kadar ölçeklenmesine yardımcı oluyor.

Neden Bahar Rulo Sarma Makinesi Tedarikçiniz Olarak Bizi Seçmelisiniz??

- Üzerinde 20 Yıllarca deneyim gıda işleme makinelerinde

- Özelleştirilebilir çözümler iş gereksinimlerinize uyacak şekilde

- Yüksek kaliteli paslanmaz çelik konstrüksiyon dayanıklılık için

- Rekabetçi fabrika doğrudan fiyatları

- Küresel teslimat ve kurulum desteği

Sık sorulan sorular (SSS)

1. Makine farklı boyutlarda sarmalayıcılar yapabilir mi??

Evet, çoğu makine ambalaj çapının ve kalınlığının ayarlanmasına izin verir.

2. Çalıştırmak zor mu?

HAYIR. Temel eğitim ile, bir kişi kolayca çalıştırabilir.

3. Makineyi hamur tatlısı veya samosa sarmalayıcıları için kullanabilir miyim??

Evet, küçük ayarlamalarla, makine birden fazla türde sayfa üretebilir.

4. Nakliye ve kurulum ne kadar sürer?

Konum ve modele bağlı olarak genellikle 2-6 hafta.

5. Garanti süresi nedir?

Çoğu makine bir 1–2 yıl garanti.

Gelecek İçin

A bahar rulo sarma makinesi geniş ölçekte yüksek kaliteli ambalajlama ürünleri üretmeyi amaçlayan gıda işletmeleri için ezber bozan bir ürün. İster küçük bir restoran ister büyük bir dondurulmuş gıda fabrikası işletiyor olun, Doğru makineye yatırım yapmak tutarlı ürün kalitesi sağlar, maliyet tasarrufu, ve daha yüksek kar.

Güvenilir bir üretici seçerek, sadece bir makineye değil, aynı zamanda gıda üretim yolculuğunuzda uzun vadeli bir ortağa da sahip olursunuz.

İşletmenizi bir yükseltmeye hazırsanız bahar rulo sarma makinesi, Size özel bir çözüm için bugün bizimle iletişime geçin.