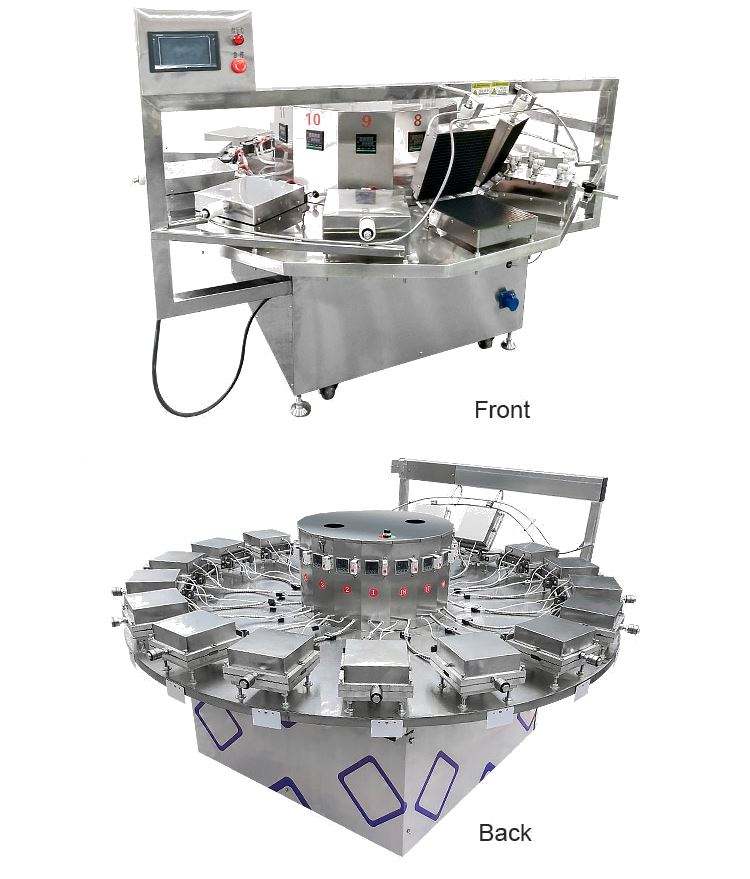

Automatic Ice Cream Cone Maker for Commercial Production

Bir automatic ice cream cone maker provides a seamless solution for large-scale cone production. The machine mixes batter, bakes it evenly, and shapes cones automatically. Unlike manual models, automatic machines reduce labor, hijyeni iyileştirmek, and increase output.

Features of Automatic Ice Cream Cone Maker

- PLC kontrol sistemi for automatic operation.

- Temperature Adjustment for precise cone texture.

- High Output Capacity, kadar 12,000 saat başına adet.

- Gas or Electric Heating Options depending on energy preference.

Technical Parameters of Automatic Ice Cream Cone Maker

| Model | Kapasite (adet/saat) | Güç (KW) | Gerilim (V/Hz) | Koni Boyutu (mm) | Isıtma yöntemi | Boyutlar (mm) | Ağırlık (kilogram) |

|---|---|---|---|---|---|---|---|

| ACM-40 | 2,000 - 3,500 | 4.0 | 220V / 50Hz | 45–110 | Elektrik/Gaz | 1600×1000×1300 | 420 |

| ACM-80 | 5,000 - 6,500 | 7.5 | 380V / 50Hz | 50–125 | Gaz/Elektrik | 2500×1500×1700 | 820 |

| ACM-120 | 8,000 - 10,000 | 10.5 | 380V / 50Hz | 55–140 | Gaz/Elektrik | 3500×1900×2000 | 1,450 |

Commercial Ice Cream Cone Maker for Small and Medium Shops

A ticari dondurma külahı makinesi is ideal for small to medium-sized businesses. These machines combine affordability with moderate production capacity.

Advantages of Commercial Ice Cream Cone Maker

- Kompakt tasarım, saving shop space.

- User-friendly operation with simple controls.

- Moderate output suitable for daily retail needs.

- Lower investment compared to industrial-scale models.

Technical Specifications of Commercial Cone Maker

| Model | Kapasite (adet/saat) | Güç (KW) | Gerilim (V/Hz) | Koni Boyutu (mm) | Boyutlar (mm) | Ağırlık (kilogram) |

|---|---|---|---|---|---|---|

| DT-6.9.15 | 600 - 1,200 | 2.5 | 220V / 50Hz | 45–100 | 1200×700×1000 | 200 |

| DT-18 | 1,200 - 2,000 | 3.5 | 220V / 50Hz | 50–120 | 1500×900×1100 | 320 |

Industrial Ice Cream Cone Maker for Large-Scale Factories

. industrial ice cream cone maker is designed for factories producing cones in bulk. These machines often integrate into full production lines, including batter mixers, baking ovens, rolling devices, soğutma konveyörleri, ve paketleme üniteleri.

Key Benefits of Industrial Ice Cream Cone Maker

- Üretme yeteneğine sahip 10,000 - 15,000 saat başına koni.

- Fully automatic with minimal labor requirements.

- Customizable cone molds for various cone sizes and textures.

- Enerji tasarruflu ısıtma sistemleri.

Industrial Ice Cream Cone Maker Technical Parameters

| Model | Kapasite (adet/saat) | Güç (KW) | Gerilim (V/Hz) | Koni Boyutu (mm) | Isıtma yöntemi | Boyutlar (mm) | Ağırlık (kilogram) |

|---|---|---|---|---|---|---|---|

| DT-150 | 12,000 - 14,000 | 14.0 | 380V / 50Hz | 60–150 | Gaz/Elektrik | 4500×2200×2300 | 2,100 |

| DT-200 | 15,000 - 18,000 | 18.5 | 380V / 50Hz | 65–160 | Gaz/Elektrik | 5500×2500×2500 | 2,800 |

Waffle Cone Making Machine and Sugar Cone Baking Machine

. waffle koni yapma makinesi is a synonym often used for cone makers designed to produce textured waffle cones. Benzer şekilde, . şeker koni pişirme makinesi focuses on producing sweet, crispy sugar cones. Both machines work on similar principles but differ in mold designs and recipe adaptations.

Features of Waffle Cone Making Machine

- Embossed mold designs for traditional waffle texture.

- Adjustable cone thickness.

- Optional chocolate-coating feature.

Features of Sugar Cone Baking Machine

- Produces thin, crisp cones.

- Uniform baking with automated temperature control.

- High-speed production for commercial demand.

Ice Cream Wafer Cup Maker and Edible Cone Forming Machine

Apart from cones, many businesses also use an ice cream wafer cup maker veya edible cone forming machine. These machines expand product variety by producing cups, bowls, or custom-shaped edible containers.

Advantages of Wafer Cup Maker

- Expands product offering beyond traditional cones.

- Provides sturdy and attractive edible containers.

- Increases profitability by catering to premium dessert markets.

Maintenance of Ice Cream Cone Maker

Proper maintenance ensures consistent performance and extends machine life.

- Günlük Temizlik: Remove batter residues from baking plates.

- Düzenli Yağlama: Apply food-safe lubricants to moving parts.

- Heating System Check: Inspect electrical or gas components regularly.

- Calibration: Maintain accurate temperature and timing controls.

Choosing the Right Ice Cream Cone Maker

When investing in a cone maker, dikkate almak:

- Üretim kapasitesi – Small shop vs. industrial factory.

- Isıtma Tipi – Gas is cheaper for large production; electric is cleaner.

- Koni Çeşitleri – Sugar cones, waffle konileri, or wafer cups.

- Bütçe & Uzay – Machine footprint and investment.

- Satış sonrası desteği – Ensure supplier offers technical support and spare parts.

Future Trends in Ice Cream Cone Maker Technology

- Smart Control Systems – IoT monitoring for performance tracking.

- Eco-Friendly Production – Reduced energy consumption and emissions.

- Özelleştirme – Growing demand for flavored or shaped cones.

- Entegrasyon – Cone makers integrated into automated dessert lines.

Choose Us Ice Cream Cone Maker DT Food Machine Manufacturer

. dondurma koni üreticisi has revolutionized the frozen dessert industry by enabling high-quality, hijyenik, and large-scale production of cones. İtibaren automatic ice cream cone makers for large factories to commercial waffle cone machines for local shops, these machines provide a wide range of solutions to meet diverse business needs. By considering technical parameters, üretim hedefleri, and machine features, businesses can select the right equipment to enhance efficiency and profitability.