Dondurulmuş Patates Kızartması Makinesi Otomatik Patates Kızartması İşleme Tesisi

Fransızca patates kızartması üretim hattı patatesin patates kızartmasına dönüştürülmesine yönelik otomatik ve gelişmiş bir üretim çözümüdür.

Otomatik patates kızartması işleme tesisi patates yıkama ve soyma makinesi içerir, patates kızartması kesici makinesi, haşlama makinesi, susuzlaştırma makinesi, patates kızartması fritöz makinesi, sopa makinesi, soğutma makinesi, hızlı dondurucu, otomatik paketleme makinası ve yardımcı ekipmanları.

Başvurdu: Patates cipsi, tatlı patates cipsi, uzun muz cipsi, patates kızartması, taze patates kızartması, dondurulmuş patates kızartması, muz çipleri vb..

Kapasite: 50-100kg/s, 200-250kg/s, 350-400kg/s, 500kg/s, 1000kg/s, 1500kg/s, 2000kg/h ve özelleştirilmiş kapasite.

Dondurulmuş Patates Kızartması Üretim Hattı Uygulaması

Dondurulmuş patates kızartması yapma makinesi dondurulmuş patates kızartması üreticileri için gelişmiş bir çözümdür. Daha büyük patates kızartması fabrikaları için otomatik patates kızartması makinesi üretim hattıdır., veya orta boy fabrika veya yeni patates kızartması fabrikası için küçük ölçekli dondurulmuş patates kızartması üretim hattı. Patates işleme tesislerimiz, işçiliği büyük ölçüde azaltarak yatırımcılara iyi getiri sağlıyor, ürün kalitesinin iyileştirilmesi, verimlilik ve pazar payı sağlamak.

Dondurulmuş cips yapma makinesi, hattın çeşitli cipsler yapmasını isteyen atıştırmalık yiyecek üreticileri arasında da popülerdir, patates cipsi gibi, muz cipsi, tatlı patates cipsi vb.. Ve hammaddelerin mevsimselliği nedeniyle, diğer ürünleri üretebilmek için sezon dışı üretime yönelik bir üretim hattına ihtiyaçları var.

Dondurulmuş Patates Üretim Hattı Tanıtımı

Dondurulmuş Patates Kızartması Üretim Hattı Açıklaması

Ticari patates kızartması makinesi, hammadde yıkama ve soyma makinesini kapsayan komple bir üretim hattıdır., haşlama makinesi, patates kesici, patates kızartması fritözü, hızlı dondurucu, otomatik tartım ve torbalama makinesi.

Ve patates işleme tesisini farklı işletme büyüklüklerini karşılayacak şekilde özelleştiriyoruz. Öyleyse, Saatte 50kg kapasiteli yarı otomatik patates kızartması üretim hattımız var, aynı zamanda saatte 100kg kapasiteli küçük ölçekli patates kızartması üretim hattımız da var., ve saatte 2000 kg'a kadar tam otomatik dondurulmuş patates kızartması üretim hattı. Ayrıca, Patates kızartması yapma makinesini müşterinin ihtiyaç duyduğu kapasiteye göre özelleştiriyoruz.

Satılık Patates Kızartması Üretim Hattı Şartname

Isıtma yöntemi: Elektrikli ısıtma / Gaz ısıtma

Makine malzemeleri: Gıda sınıfı 304 Paslanmaz Streel Malzemeleri, En iyi kalite yapılmış

Yağ ısıtma sıcaklığı: 0℃ - 300 ℃ (Fahrenheit 32 ° F ila 572.0 ° F)

Kapasite: 50KG/saat ila 2000kg/saat (Yüksek kapasite özelleştirilebilir)

Fabrika alanı gereksinimi: Üretim hattını fabrika boyutuna ve kat planına göre özelleştirebiliriz.

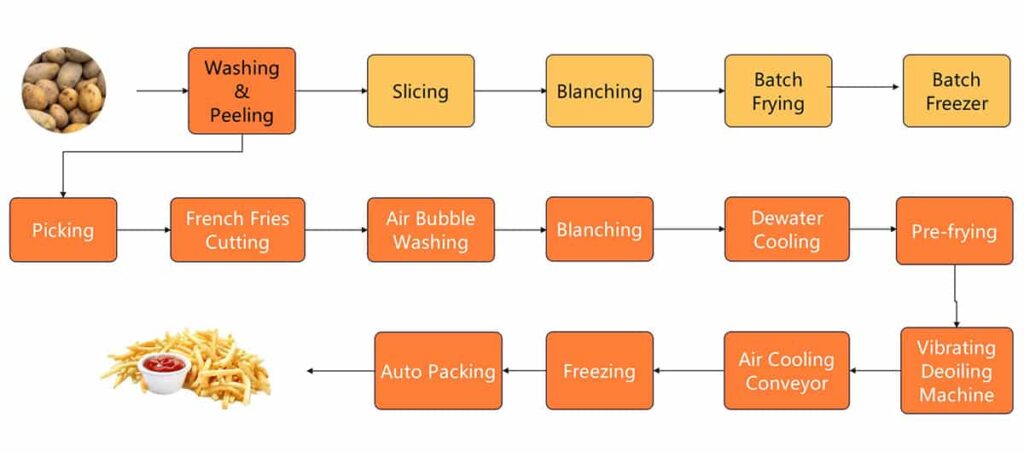

Tam Otomatik Patates Kızartması Makinesi Akış Şeması

Küçük ölçekli patates kızartması üretim hattı yarı otomatik ve tam otomatik patates kızartması üretim hattı işleme akışını içerir.

Patates Kızartması Makinesi Özellikleri

Patates soyma makinesi

Bu sürekli yıkama ve soyma makinesidir yıkama, soyma ve boşaltma.

Çünkü pürüzlü ve oluklu fırçalar, patateslerin tamamen soyulmasını sağlayan sert kıllı fırça ve zımpara fırçasından oluşmaktadır..

Ayrıca, Spriyal tipi soyma makinesi patates foward'ı ve diğer uçtan deşarjı, dilimleme işleminden önce konveyör bantlarını seçmeye itin.

Dahası, Patates yıkamak ve soymak için uygundur, tatlı patates, manyok, zencefil, soğan, havuç vb..

Fransız Kızartma Patates Kesici Makinası Elektrikli

patates kızartması kesme makinası, yüksek çıkışlı ticari patates kızartması kesicidir. Ve fransız çubukları boyutu 7*7mm, 8*8mm, 10*10mm, ve özel yapım bıçak ayarlanarak değiştirilebilir.

Patates kızartması kesici makinesi diğer kök sebzeler için de uygundur, havuç gibi, manyok, vesaire.

Son ürün pürüzsüz, tek tip ve kesintisiz.

Kızartmadan önce patatesleri hafifletme

Bu, Fransız çubuklarının rengini korumak ve ürünün tadını korumak için haşlama makinesidir..

Patates cipsi dallanma süresi hakkında 5 Sıcak su sıcaklığında 15 dakika 70 ℃ (158.0 ° f). Ve paslanmaz çelik hasır kayış frekans dönüşüm hızı düzenlemesine sahiptir, böylece haşlama süresi ve hızı ayarlanabilir.

Müşterinin seçebileceği gaz ısıtmalı sürekli dallanma makinesi ve elektrikli ısıtmalı sürekli dallanma makinesi bulunmaktadır..

Patates Susuzlaştırma Makinesi

Hava soğutma makinesi, kızartmadan önce suyu uzaklaştırır ve dallanmış patates çubuklarının sıcaklığını soğutur. Kızartma süresini kısaltır ve patates kızartmasının kaliteli lezzetini sağlar..

Ve daha iyi etkiye sahip olmak, Hava kurutma ve susuzlaştırma konveyör bandından önce titreşimli bir deoiling macine kullanılması gerekmektedir.

patates kızartması fritöz makinesi

Küçük ölçekli patates cipsi bitkisi için, sepet tipi fritöz veya yuvarlak tencere kızartma makinesi saatte 200 kg'ın altındaki kapasiteler için ideal seçimdir.

Fakat, tam otomatik patates kızartması üretim tesisi için, sürekli kızartma makinesi Daha büyük kapasite ve daha az işçilikle kızartma süresinin sürekli çalışmasını sağlamak için en iyi seçenektir. En iyi patates kızartması makinesi paslanmaz çelik malzemedir ve kızartma süresi ayarlanabilir ve yağ sıcaklığı ayarlanabilir.

Ayrıca, yağ doldurma işlemini otomatikleştirmek için fritözü de özelleştirebiliriz, yağ geri dönüşümü, yağ filtreleme ve kendi kendini temizleme sistemi. Bu, üretim verimliliğini büyük ölçüde artıracaktır, yağ kullanımını uzatır ve daha kaliteli patates kızartması sağlar.

Sopa makinesi

Titreşimli Yağ Giderme makinesi, kızartma sonrasında patates kızartmasının yüzeyindeki yağı çıkarmak için gereklidir..

Çünkü, Kızartma hattından çıkan kızartılmış Fransız çubukları normalde ürünün yağlı olmasına neden olan ve üretim ortamını kirletebilecek bazı yağlar içerir.. Öyleyse, Yağ alıcı plakalı titreşimli makine, yağı cips yüzeyinden arındırmak ve üretim alanını temiz tutmak için iyidir.

DAHA FAZLA NEDİR, Titreşimli işlem sırasında, Cipsler hareket ediyor ve bir sonraki sürece bile yayılıyor.

Soğutma makinesi

Soğutma konveyörü, patates kızartmasına rüzgar üfleyen vantilatörlerle donatılmıştır. Bu nedenle yüzey sıcaklığı doğal kuvvetli rüzgar nedeniyle çok az düşer. Hızlı dondurma işleminden önce bu önemli bir işlemdir.

Patates kızartmasından düşen yağın alınması için soğutma konveyörünün altındaki yağ alma plakası isteğe bağlıdır.

Kızartma Dondurucu Tünel Dondurucular IQF Dondurucular

Patates kızartması hızlı dondurucu, herhangi bir topak oluşmasına veya ürünün birbirine yapışmasına neden olmadan büyük miktarlarda patates kızartmasını kısa sürede dondurmak için uygulanabilir..

Beslenecek malzemenin merkez sıcaklığı:<20 C

Deşarj sıcaklığı: -18°C

Donma süresi: 15 dakika ila 45 dakika.

Otomatik makineyi tartı ile paketleme, Dolgu ve Torba Yapımı

Dondurulmuş patates kızartmasını otomatik olarak plastik torbaya paketlemek için, otomatik kese doldurma ve kapatma makinesi ideal seçimdir. Asansör içerir, çok başlı tartım, düz, Tarih yazdırma işlevine sahip çanta yapım cihazları, ve bir son ürün konveyörü.

DAHA FAZLA NEDİR, Cips paketleme makinesi yüksek verimlilik avantajına sahiptir, doğru tartma, ve patates kızartması işleme hattında sürekli çalışma.

Patates Kızartması İşleme Hattı Parametresi

Dondurulmuş Patates Kızartması Makine Listesi yalnızca referans amaçlıdır:. Ve patates kızartması işleme hattını müşterinin fabrika düzenine göre özelleştirebiliyoruz, Gerilim, son ürün çeşitleri, ambalaj türü vb..

| HAYIR. | Makine adı | Miktar | Birim | Voltaj oranı |

| 1 | Asansör | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 2 | Patates yıkama ve soyma makinesi | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 3 | Konveyör bandını seçin | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 4 | Patates kesici | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 5 | Kova sprey kaldırma | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 6 | Niteliksiz Fransız kızartması toplama makinesi | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 7 | Durulama makinesi | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 8 | Haşlama makinesi | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 9 | Titreşim kurutucu | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 10 | Hava soğutmalı kurutucu | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 11 | Asansör | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 12 | Sürekli kızartma makinesi | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 13 | Titreşimli yağ giderme makinesi | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 14 | Hava soğutmalı kurutucu | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 15 | Patates Kızartması Yayma Makinası | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir | |

| 16 | Dondurucu | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

| 17 | Paketleme Makinası | 1 | Ayarlamak | 380V 50HZ 3ph Özelleştirilebilir |

Patates Kızartması Yapma Makinesi Fabrikası

Avantaj

Tek durak yemek makineleri fabrikası

30 Yıllar R&D Tarihi

Kararlı Makine Performansı

Zamanında teslimat

Garanti

12 Aylar Kalite Garantisi

Tüm Yaşam Teknik Desteği ve Yedek Parça Hizmeti

Hizmet vermek

Faaliyette satış sonrası destek, Bakım.

Fabrikada çevrimiçi veya kapalı satırda ücretsiz eğitim

Müşteri fabrikasında yerinde kurulum

Yeni İş Planlayıcısı için genel iş tavsiyeleri.

Alıcının Ülkesine Teslimat Hizmetleri

Patates Kızartması Makinesi Fiyatı

Üretim hattımızı daha yüksek etkinlik için güncellemek için profesyonel teknik mühendis ekibimiz ve ürün geliştirme ekibimiz var, Daha az üretim ve daha iyi kullanıcı tatmin edici. Ayrıca, Müşteri ihtiyaçlarını işlerine doğru çözümle anlıyor ve hızlı bir şekilde yanıtlıyoruz.

Patates kızartması üretim tesisi maliyeti için şimdi ekibimizle iletişime geçmenizden memnuniyet duyarız..

Dondurulmuş patates kızartması hattında kullanılan en iyi patates hangisidir??

Shepody, New Brunswick kökenli beyaz tenli bir patates çeşididir., Kanada ve kaynatma için kullanılır, pişirme, ve Fransız kızartması. onun dönemli olan 19-21%, düşük indirgeyici şeker içeriği≤ 0.4% , özellikle kızartma işlemine uygundur.

DAHA FAZLA NEDİR, fast food restoranlarında patates kızartması ve süpermarketlerde patates cipsi fabrikalarda seri olarak üretiliyor. İyi şekillendirilmiş, hafif gözlü Shepody'nin üretim sırasında soyulması kolaydır, ve ortaya çıkan patates cipsi ve patates kızartması nadiren delik ve yara izi gösteriyor.

Öyleyse, Shepody, dondurulmuş patates kızartması üretimi için ideal patates çeşididir..

İlgili Makineler

Patates cipsi makineleri, Banana Cips Üretim Hattı, Penauts kızartma hattı. sürekli fritöz, Küçük ölçekli patates cipsi üretim hattı