Patates Kızartması Üretim Hattına Giriş

. Patates kızartması üretim hattı gıda işleme endüstrisinde önemli bir ekipman parçasıdır, Taze patateslerden çıtır ve lezzetli patates kızartmasının seri üretimini otomatikleştirmek için tasarlandı. İster fast food zincirlerinde olsun, dondurulmuş gıda fabrikaları, veya catering tedarikçileri, yüksek verimliliğe olan talep, sürekli, ve hijyenik üretim hatları hızla arttı. Bu makale, patates kızartması üretim hattının her alanında size rehberlik edecektir., Hammadde hazırlığından son paketlemeye kadar, işlevselliğine odaklanmak, bileşenler, faydalar, ve uygulamalar.

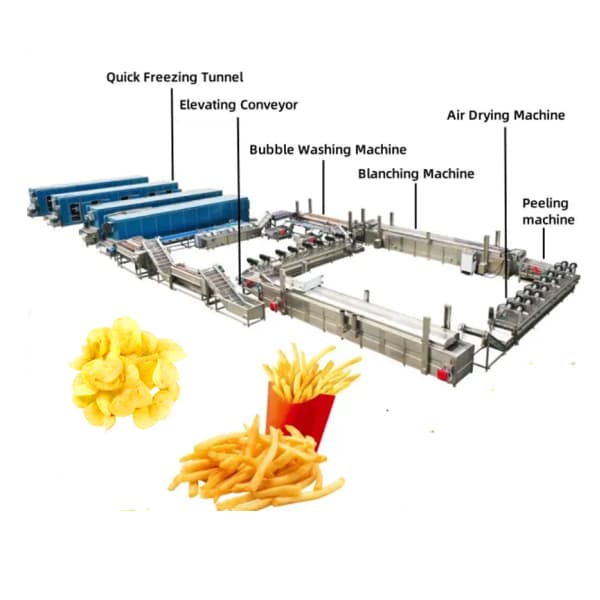

Patates Kızartması Üretim Hattı Nedir??

Tam otomatik patates patates kızartması üretim hattı yıkama gibi belirli görevleri yerine getiren bir dizi birbirine bağlı makinedir., soyma, kesme, ağartma, kurutma, kızartma, yağlama, donmak, ve ambalaj. Bu sistem eşitliği sağlar, tatmak, Endüstriyel ölçekte patates kızartmasının güvenliği ve güvenliği.

Hat yarı otomatik veya tam otomatik olabilir, ve genellikle çeşitli kapasiteleri idare edecek şekilde tasarlanmıştır, küçük ölçekli operasyonlardan saatte birkaç tonu aşan büyük ölçekli ticari üretime kadar.

Patates Kızartması Üretim Hattının Ana Bileşenleri

1. Patates Yıkama ve Soyma Makinası

Bu üretim hattındaki ilk adımdır. Yıkayıcı kiri temizler, taşlar, ve diğer yabancı maddeler, soyma makinesi, patates etine zarar vermeden kabuğu çıkarmak için zımpara ruloları veya fırçalar kullanır.

Ana Özellikler:

- Yüksek verimlilik

- Düşük su tüketimi

- Patateslerde minimum hasar

2. Patates Kesme Makinası

Bir kez temizlenip soyuldu, patatesler onları eşit şeritler halinde dilimleyen bir kesme makinesine beslenir. Boyut, belirli ürün gereksinimlerine göre ayarlanabilir.

Popüler Kesim Boyutları:

- 7×7 mm

- 10×10mm

- 12×12 mm (kalın kızartmalar için)

3. Durulama ve Haşlama Makinası

Beyazlatma çok önemlidir:

- Fazla nişastanın giderilmesi

- Doğal rengin korunması

- Kızartmak veya dondurmak için patates kızartması hazırlama

Makine, şeritleri beyazlatmak için kontrollü sıcaklıklarda sıcak su veya buhar kullanır..

4. Kurutucu (Hava Kurutucu veya Susuzlaştırma Makinesi)

Haşlamadan sonra, nem içeriğini azaltmak için patates kızartmasının kurutulması gerekir. Bu, nihai ürünün kalitesini artırır ve kızartma sırasında yağ emilimini azaltır..

5. Sürekli Kızartma Makinesi

Sürekli fritöz, patates kızartmasının tutarlı bir sıcaklıkta eşit şekilde kızartılmasını sağlar. Çıtır bir dış katman ve yumuşak bir iç doku sağlamak için yağ sıcaklığı ve kızartma süresi otomatik olarak kontrol edilir.

Kullanılan Kızartma Yağları:

- Hurma yağı

- Ayçiçek yağı

- Soya yağı

6. Yağ Alma Makinesi

Kızartma sonrası, santrifüjlü bir yağ giderici fazla yağı giderir, kızartmaların daha az yağlı ve sağlıklı olmasını sağlar. Bu adım aynı zamanda raf ömrünü ve tadı da artırır.

7. Dondurma Makinesi (Dondurulmuş Patates Kızartması İçin)

Dondurulmuş ürünler için, patates kızartması bir IQF'ye gönderilir (Bireysel hızlı donma) tazeliği ve dokuyu korumak için tünel. Bu makine, patates kızartmasını -18°C veya daha düşük sıcaklıkta birkaç dakika içinde dondurur.

8. Ambalaj makinesi

Son adım, bitmiş kızartmaları paketlemek. Raf ömrünü uzatmak için genellikle vakumlu veya nitrojen dolu paketleme makineleri kullanılır..

Ambalaj Formatları:

- Plastik poşetler

- Karton kutular

- Mühürlü torbalar

Teknik Özellikler Tablosu

| Makine adı | Model | Kapasite (kg/s) | Güç (KW) | Malzeme |

|---|---|---|---|---|

| Yıkama & Soyma makinesi | WP-1000 | 1000 | 3.0 | Paslanmaz çelik |

| Patates Kesme Makinası | PC-600 | 600 | 1.5 | Paslanmaz çelik |

| Ağartma makinesi | BM-1000 | 1000 | 15 | ONLARIN 304 |

| Kurutucu | DH-800 | 800 | 2.2 | ONLARIN 304 |

| Kızartma Makinesi | FRY-1000 | 1000 | 36 | ONLARIN 304 |

| Yağ Alma Makinesi | DO-800 | 800 | 1.5 | ONLARIN 304 |

| Donma Tüneli | IQF-1000 | 1000 | 40 | Paslanmaz çelik |

| Paketleme Makinası | PM-300 | 300 torba/saat | 2.5 | ONLARIN 304 |

Patates Kızartması Üretim Hattı İş Akışı

- Çiğ Patates Besleme

- Yıkama ve Peeling

- Şeritler halinde Kesme

- Durulama ve Haşlama

- Kurutma

- Kızartma

- Yağdan arındırma

- Soğutma veya Dondurma

- Paketleme ve Sızdırmazlık

Bu sistematik süreç hijyen sağlar, tutarlılık, ve tüm hat boyunca üretkenlik.

Otomatik Patates Kızartması Üretim Hattı Kullanmanın Avantajları

✅ Yüksek verimlilik

Otomatik sistemler iş gücüne bağımlılığı azaltır ve günlük çıktıyı önemli ölçüde artırır.

✅ Tutarlı Kalite

Otomasyon, her kızartmanın tutarlı boyutta olmasını sağlar, renk, ve tat.

✅ Hijyenik Üretim

Makineler paslanmaz çelikten üretilmiştir ve gıda güvenliği standartlarına uygundur (HACCP, ISO, CE).

✅ Enerji ve Yağ Tasarrufu

Modern sistemler kızartma yağını geri dönüştürüyor ve enerji tasarruflu ısıtma sistemleri kullanıyor.

✅ Özelleştirilebilir

Üretim hatları müşteri ihtiyaçlarına göre özelleştirilebilir: dondurulmuş patates kızartması, taze patates kızartması, kıvırcık patates kızartması, veya patates kızartması.

Patates Kızartması Üretim Hatlarının Uygulamaları

Patates kızartması üretim hatları çeşitli ortamlarda kullanılmaktadır:

- Dondurulmuş Gıda İşleme Tesisleri

- Fast Food Zincirleri

- Yemek Hizmetleri

- Okul Kantinleri ve Hastaneler

- Atıştırmalık Yiyecek Üreticileri

- Startup'lar ve KOBİ Gıda Fabrikaları

Her ikisi için de idealdirler dondurulmuş patates kızartması Ve yemeye hazır sıcak patates kızartması.

Bakım ve Temizlik İpuçları

- Günlük Temizlik: Her makinenin gıda sınıfı dezenfektanlarla temizlendiğinden emin olun.

- Düzenli Yağ Değişimleri: Fritöz yağını önerilen aralıklarla değiştirin.

- Yağlama: Mekanik parçalar bakım kılavuzuna göre yağlanmalıdır..

- Denetleme: Haftalık inceleme, potansiyel arızaların erken tespit edilmesine yardımcı olur.

Doğru Patates Kızartması Üretim Hattı Nasıl Seçilir

Bir satır seçerken, aşağıdakileri göz önünde bulundurun:

- Üretim kapasitesi (kg/saat veya ton/gün)

- Nihai Ürün Türü (dondurulmuş, taze, kaplamalı patates kızartması)

- Bütçe Kısıtlamaları

- Alan Kullanılabilirliği

- Otomasyon seviyesi (yarı veya tam otomatik)

- Satış sonrası hizmet & Garanti

Kurulum sağlayabilecek güvenilir üreticilerle çalışın, eğitim, ve özelleştirme.

Patates Kızartması Üretim Hattının Tahmini Maliyeti

Fiyat kapasiteye göre değişmektedir, otomasyon seviyesi, ve konfigürasyon.

| Satır kapasitesi | Otomasyon | Fiyat aralığı (Amerikan Doları) |

|---|---|---|

| 200–300 kg/saat | Yarı | $20,000-40.000$ |

| 500–800 kg/saat | Tam dolu | $60,000–90.000$ |

| 1–2 ton/saat | Tam dolu | $120,000–200.000$ |

| >5 ton/saat | Endüstriyel | $300,000+ |

🧪 Her İşlem Adımının Derinlemesine Analizi

🥔 1. Patates Seçimi ve Kalite Kontrolü

Bütün patatesler patates kızartması için uygun değildir. Russet Burbank veya Innovator gibi yüksek nişastalı çeşitler dokuları ve kızartma davranışları nedeniyle tercih ediliyor.

Ön sıralama parametreleri şunları içerir::

- Boyut: Tekdüze orta ila büyük boyutlar

- Deri: Minimal morluklar ve filizlenme

- Kuru madde içeriği: İdeal >20%

Görsel veya lazer sınıflandırma sistemlerini otomatikleştirerek, üreticiler kusurları erken aşamada azaltır, aşağı yönlü maliyetlerden tasarruf.

🧼 2. İleri Yıkama Teknikleri

Modern yıkama sistemleri yüksek basınçlı püskürtme nozullarını kullanır, döner fırçalar, ve sadece toprağı değil pestisit kalıntılarını da gidermek için kabarcık sirkülasyonu.

Bazı sistemler entegre:

- Su geri dönüşüm tankları

- Tortu filtreleri

- UV sterilizatörleri

Bunlar su tüketimini azaltır ve yeşil işleme standartlarını karşılar.

🧊 3. Haşlama Sıcaklığı Optimizasyonu

Uygun beyazlatma genellikle şu hızda çalışır: 75–85°C, 3–5 dakika şerit boyutuna bağlı olarak.

Haşlamanın faydaları:

- Enzimleri etkisiz hale getirir

- Kızartma rengini iyileştirir

- Akrilamid oluşumunu engeller

- Dokuyu stabilize eder

Bazı satırlar kullanılıyor sıcak hava ağartıcıları enerji tasarrufu performansı için.

🔥 4. Kızartma: Lezzet & Doku Bilimi

Anahtar faktörler:

- Yağ sıcaklığı: 160°C–180°C

- Zaman: 30–60 saniye ön kızartma için (dondurulmuş patates kızartmasında), taze için daha uzun

Yüksek verimli fritözler şunları içerir::

- Isı eşanjörleri

- Otomatik filtreleme

- Yağ seviyesi dengeleme sistemleri

Çok bölgeli fritözlerin kullanımı çeşitli son ürünler için kişiselleştirmeye olanak tanır (Örneğin., kırışık kesilmiş patates kızartması vs bağcıklı patates kızartması).

🥶 Patates Kızartması Çeşitleri ve Üretim Hattı Ayarlamaları

| Patates Kızartması Türü | Çizgi Farklılıkları | Son Form |

|---|---|---|

| Dondurulmuş Patates Kızartması | IQF dondurmayı içerir, nitrojen paketleme | Dondurulmuş ürün |

| Taze Patates Kızartması | Soğutma konveyörleri gerektirir, hızlı sevkiyat | Kızartmaya hazır poşetler |

| Kaplamalı Patates Kızartması | Kaplama aplikatörü + haşlamadan sonra ekstra kurutucu | Gevrek, hamur kaplı |

| Kıvırcık/Waffle Kızartması | Özel kesici + daha yüksek hassasiyetli kızartma ünitesi | Özel dokular |

| Baharat Aromalı Patates Kızartması | Baharat bardağı + yağ püskürtücü + lezzet dozları | Önceden terbiye edilmiş atıştırmalıklar |

Her tip özel konfigürasyonlar gerektirir, kızartma hızından baharat karıştırıcılarına kadar.

❓ Ortak RFQ'lar (Sık sorulan sorular)

Çeyrek: 500 kg/saatlik bir hat için kaç işçiye ihtiyaç vardır??

A: Tam otomatik bir hat için: 3–5 operatör (besleme, izleme, ambalajlama). Yarı otomatik 8-10'a kadar gerektirebilir.

Çubuk: Hat, tatlı patates veya taro gibi diğer kök sebzeleri işleyebilir mi??

A: Evet. Küçük bıçak ayarlamaları ve haşlama süresi değişiklikleriyle, tatlı patatesleri işleyebilir, havuç, veya manyok şeritleri.

Çeyrek: AB/ABD'ye ihracat için hangi sertifikalara ihtiyaç vardır??

A:

- CE (AB Uyumluluğu)

- FDA uyumlu malzemeler (Amerika Birleşik Devletleri için)

- ISO 9001 / HACCP

Çeyrek: Sipariş verdikten sonra teslim süresi nedir?

A: Makinenin özelleştirilmesine ve kapasitesine bağlı olarak normalde 25-45 iş günü.

Q5: Yağ fritözde tekrar kullanılabilir mi??

A: Evet. Sistem, temiz yağın güvenli bir şekilde yeniden kullanılması için otomatik yağ filtresi ve sirkülasyon sistemi içerir.

🏭 Önerilen Tedarikçi: DT Food Machine Co., Ltd..

Küresel deneyime sahip güvenilir bir üretici arıyorsanız, DT Food Machine Co., Ltd.. Patates kızartması üretim hatlarında lider uzman olarak öne çıkıyor.

Neden DT Gıda Makina A.Ş., Ltd.?

- 🛠 20+ yıllık üretim tecrübesi

- 📦 Patates yüklemeden paketlemeye kadar anahtar teslim çözümler

- 🌍İhraç edildi 60+ ABD dahil ülkeler, Meksika, Suudi Arabistan, Nijerya

- 🧰Yerinde kurulum ve uzaktan video desteği sağlar

- 🧪 R Teklifleri&Lezzet özelleştirme ve kaplama uygulamalarına yönelik D hizmetleri

Popüler modeller:

- DT-FRY1000 - 1000 kg/saat otomatik hat

- DT-MINI500 – Kompakt 500 startuplar için kg/saat hattı

- DT-IQF2000 – Spiral donduruculu dondurulmuş patates kızartması hattı

📞 DT Gıda Makina A.Ş. ile iletişime geçin, Ltd.. Teklif veya teknik çizim için e-posta veya WhatsApp aracılığıyla.

📈 Patates Kızartması Üretiminde Endüstri Eğilimleri

1. Akıllı Otomasyon & Nesnelerin İnterneti Entegrasyonu

Gelişmiş hatlarda dokunmatik ekran arayüzlü PLC bulunur, gerçek zamanlı veri takibi, kestirimci bakım uyarıları, ve bulut entegrasyonu.

2. Çevre Dostu Kızartma

Yeni sistemlerde enerji tasarruflu brülörler kullanılıyor, güneş destekli kurutma, ve karbon ayak izini azaltmak için yağ filtreleme.

3. Lezzet Özelleştirme Patlaması

Küresel atıştırmalık markaları, birden fazla aroma kaplaması uygulayabilen hatlar talep ediyor (Örneğin., kırmızı biber, yer mantarı, peynir), Tüketici çeşitliliği talepleri tarafından yönlendirilen.

4. Kompakt Modüler Tasarımlar

Küçük modüler sistemler, kolay yükseltme ve bakıma olanak tanır, özellikle küçük ve orta ölçekli tesisler için faydalıdır.

📌 Çözüm: Patates Kızartması İşinizi Geleceğe Hazırlayın

İyi tasarlanmış Patates kızartması üretim hattı Başarılı patates atıştırmalığı üretiminin omurgasıdır. Doğru konfigürasyonla, klasik dondurulmuş kızartmalardan baharatlılara kadar her şeyi üretebilirsiniz, tecrübeli gurme şeritleri.

Doğru çizgiyi seçmek şu anlama gelir::

- Daha iyi yatırım getirisi

- Daha az işçilik maliyeti

- Daha yüksek ürün tutarlılığı

- İhracat düzenlemelerine uyum

İster yeni kurulmuş bir şirket olun, ister çok uluslu bir gıda şirketi olun, yüksek kaliteye yatırım yapmak, Otomatik patates kızartması üretim hattı mükemmellik ve sürdürülebilirlik ile ölçeklendirmenin anahtarıdır.