giriiş

Çıtır çıtıra olan küresel sevgi, altın rengi patates kızartması restoranlarda giderek artan bir talebe yol açtı, fast food zincirleri, ve dondurulmuş gıda endüstrileri. Bu talebi verimli bir şekilde karşılamak için, Birçok üretici ve girişimci, Otomatik Patates Kızartması Makinesi Üretim Hattı. Bu tamamen entegre sistem patates işlemeyi basitleştirir, üretkenliği artırır, ve tutarlı kalite sağlar.

keşfedeceğiz kurulumu tamamla, maliyet dökümü, Ve anahtar makine otomatik patates kızartması üretim hattının. İster küçük ölçekli bir mutfak robotu olun, ister sanayi devi olun, Bu kılavuz bilinçli kararlar vermenize yardımcı olmak için özel olarak hazırlanmıştır.

Neden Otomatik Patates Kızartması Makinesi Üretim Hattını Seçmelisiniz??

Manuel işlemeden otomatik işlemeye geçiş çok sayıda fayda sağlar:

- Daha Yüksek Verimlilik: Sürekli işlemeyle kolaylaştırılmış işlemler.

- Geliştirilmiş hijyen: Paslanmaz çelik ekipmanlar gıda sınıfı standartlarını karşılar.

- İşgücü Tasarrufu: İnsan gücü ihtiyacını yüzde 10'a kadar azaltır 70%.

- Tutarlı Kalite: Düzgün kesim, kızartma, ve ambalaj.

- Ölçeklenebilirlik: Küçük için uygun, orta, ve büyük operasyonlar.

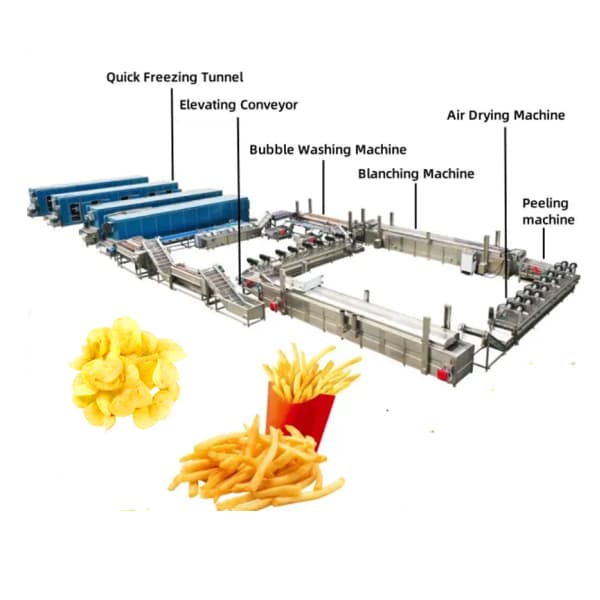

Patates Kızartması Üretim Hattındaki Çekirdek Makineleri

Üretim hattındaki her makine belirli bir rol oynar. Aşağıda temel bileşenlerin ayrıntılı bir dökümü bulunmaktadır.:

1. Patates Yıkama ve Soyma Makinası

- İşlev: Çiğ patatesleri temizler ve soyar.

- Kapasite: 300 kg/h ila 2000 kg/s

- Malzeme: Gıda sınıfı SUS304 paslanmaz çelik

2. Patates Kızartması Kesme Makinası

- İşlev: Patatesleri tekdüze çubuklar halinde keser.

- Ayarlanabilir Kesim Boyutu: Yaygın boyutlar arasında 7x7mm bulunur, 9x9 mm, ve 10x10mm.

- Bıçak Seçenekleri: Dümdüz, kırışık, veya dalga bıçağı konfigürasyonları.

3. Durulama/Kabarcık Yıkama Makinesi

- İşlev: Kesilmiş kızartmalardan yüzey nişastasını giderir.

- Teknoloji: Yüksek basınçlı hava kabarcıkları ve su spreyleri kullanır.

4. Ağartma makinesi

- İşlev: Enzimleri devre dışı bırakır, renk ve dokuyu korur.

- Sıcaklık Aralığı: 70–90°C

- Zaman Aralığı: 1–3 dakika kızartma boyutuna bağlı olarak

5. Susuzlaştırma Makinesi

- İşlev: Ağartma sonrası fazla nemi giderir.

- Tip: Hızlı kurutma için santrifüj sistemi

6. Sürekli Kızartma Makinesi

- İşlev: Patates çubuklarını altın renginde mükemmel bir şekilde kızartır.

- Isıtma Seçenekleri: Elektrikli, gaz, veya dizel

- Sıcaklık Kontrolü: 150–180°C arasında ayarlanabilir

7. Yağ Alma Makinesi

- İşlev: Daha sağlıklı kızartmalar için yağ içeriğini azaltır.

- Tip: Santrifüj döndürücü

8. Dondurma Makinesi (IQF Dondurucu)

- İşlev: Dokuyu ve tadı korumak için patates kızartmasını hızla dondurur.

- Sıcaklık: −18°C veya daha düşük

9. Tartım ve Paketleme Makinası

- İşlev: Otomatik olarak doldurur, ağırlık, mühürler, ve paketleri etiketler.

- Ambalaj Çeşitleri: Vakum paketleri, yastık çanta, veya toplu ambalaj

Üretim Hattının Tam İş Akışı

- Patates Yükleme: Çiğ patatesler bir hazneye dökülür.

- Yıkama ve Peeling: Kir ve cilt çıkarılır.

- Kesme: Temizlenmiş patatesler eşit şekilde kızartılacak şekilde dilimlenir..

- Tekrar Yıkamak: Nişastayı durular.

- Haşlama: Doğal patates rengini korur.

- Susuzlaştırma: Kızartma için patates kızartmasını hazırlar.

- Kızartma: Kızartmaları istenilen gevreklikte pişirir.

- Yağdan arındırma: Yağı azaltır ve raf ömrünü uzatır.

- Donmak (İsteğe bağlı): Dondurulmuş patates kızartması için.

- Ambalajlama: Patatesler tartılır ve torbalara konur.

Teknik Özellikler Tablosu

| Makine | Güç (KW) | Kapasite (kg/s) | Boyutlar (mm) |

|---|---|---|---|

| Yıkama & Soyma makinesi | 1.5 - 3.0 | 300 - 2000 | 1200x850x800 |

| Kesme Makinası | 1.1 - 2.2 | 300 - 2000 | 950x800x1000 |

| Kabarcık Yıkama Makinesi | 2.2 - 4.0 | 300 - 2000 | 1800x1000x1200 |

| Ağartma makinesi | 6.0 - 12 | 300 - 2000 | 2200x800x1400 |

| Susuzlaştırma Makinesi | 1.5 | 300 - 1000 | 900x600x900 |

| Kızartma Makinesi | 30 - 120 | 300 - 2000 | 5000x1200x1800 |

| Yağ Alma Makinesi | 1.5 | 300 - 1000 | 1000x800x1000 |

| IQF Dondurucu | 15 - 80 | 300 - 2000 | Özelleştirilebilir |

| Ambalaj makinesi | 2.0 - 5.0 | 300 - 2000 | 1500x800x1700 |

Maliyet bozulması: Ne Beklenmeli

Otomatik patates kızartması üretim hattına yapılan yatırım,:

- Kapasite

- Otomasyon Düzeyi

- Malzeme kalitesi

- Donmak & Paketleme Seçenekleri

Tahmini Maliyet Aralıkları:

| Üretim kapasitesi | Tip | Tahmini maliyet (Amerikan Doları) |

| 100 - 300 kg/s | Yarı otomatik hat | $10,000 - $30,000 |

| 500 - 1000 kg/s | Tam otomatik orta boy | $40,000 - $90,000 |

| 1000 - 2000+ kg/s | Endüstriyel ölçekli çizgi | $100,000 - $300,000+ |

Ek maliyetler şunları içerebilir::

- Fabrika kurulumu ve kurulumu

- Nakliye ve gümrük vergileri

- Bakım aletleri ve yedek parçalar

- Çalışan eğitimi

Fabrika Kurulum Gereksinimleri

Alan Gereksinimleri:

- Küçük çizgi (300 kg/s): 100 - 150 m²

- Büyük çizgi (2000 kg/s): 500 - 800 m²

Yardımcı programlar:

- Elektrik: 30 - 150 kuruluma bağlı olarak kW

- su: 3 - 10 m³/saat

- Fritöz Yağı: İlk doldurma 200 - 500 litre

İşgücü:

- Operatörlere ihtiyaç var: 3 - 6 (tam otomatik hat için)

- Eğitim süresi: 3 - 5 tedarikçi desteğiyle günler

Kârlılık ve yatırım getirisi

Üretim yapan orta büyüklükte bir fabrika düşünelim. 1000 kg/s:

- Günlük Çıkış: ~8.000 kg (8 saat)

- Toptan Eşya Fiyatları: $1.2 - $2.0 kg başına (bölgeye göre değişir)

- Günlük Gelir: ~9.600$ (ortalama. $1.2/kilogram)

- Aylık Gelir: ~200.000$+

YG: Yatırım genellikle geri kazanıldı 6 ile 18 Yerel pazar koşullarına bağlı olarak aylar.

Doğru Tedarikçiyi Seçmek

ile bir tedarikçi arayın:

- CE/ISO sertifikası

- Yerel kurulum hizmetleri

- Yedek parça bulunabilirliği

- Eğitim ve teknik destek

En İyi Tedarikçi Örneği: DT Food Machine Co., Ltd.. anahtar teslim çözümler sunuyor, özel tasarımlar, ve fazla ülkeye ihracat 60 ülkeler.

SSS

Çeyrek: Patates kızartmasının boyutunu ve şeklini özelleştirebilir miyim??

Evet, makineler düz kesim için birden fazla kesme bıçağını destekler, kırışık, veya patates kızartması.

Çubuk: Bu hat hem taze hem de dondurulmuş kızartmalar için uygun mudur??

Evet. Bir dondurucu ve nitrojen ambalajı ekleyerek, hat dondurulmuş patates kızartması üretebilir.

Çeyrek: Daha sonra üretimi genişletmek istersem ne olur??

Bu hatlar modüler ve ölçeklenebilir. Ek makineler veya daha büyük kapasiteli modüller eklenebilir.

Çeyrek: Hattın tamamının kurulumu ne kadar sürer??

Kurulum ve test işlemleri genellikle 7 - 15 karmaşıklığa bağlı olarak günler.

Q5: Ekipmanın bakımını nasıl yaparım?

Düzenli temizlik, aylık muayene, ve yıllık parça değişimi genellikle yeterlidir.

Çözüm

Bir yatırım yapmak Otomatik Patates Kızartması Makinesi Üretim Hattı Ve küçük ölçekli patates kızartması üretim hattı eşsiz verimlilik sunuyor, tutarlılık, ve kar potansiyeli. İster dondurulmuş patates kızartması markası piyasaya sürmeyi, ister fast food zincirlerine tedarik etmeyi düşünüyor olun, otomatik hat, ürününüzün en yüksek standartları karşılamasını sağlar.

Ölçeklenebilir konfigürasyonlarla, güvenilir performans, ve yüksek yatırım getirisi, bu üretim hattı herhangi bir gıda işleme girişimcisi veya yatırımcısı için stratejik bir hamledir.