Spring rolls are one of the most beloved snacks worldwide, enjoyed for their crisp texture and delicious fillings. Для ресторанов, предприятия общественного питания, and food manufacturers, producing consistent, high-quality spring roll wrappers is a challenge if done manually. Вот где а Машина для упаковки спринг-роллов становится необходимым. This advanced piece of food processing equipment automates wrapper production, обеспечение эффективности, гигиена, и экономическая эффективность.

We will dive deep into everything you need to know about Спринг -рулонные машины—their features, преимущества, working principle, Технические спецификации, and how they can transform your food business.

What is a Spring Roll Wrapper Machine?

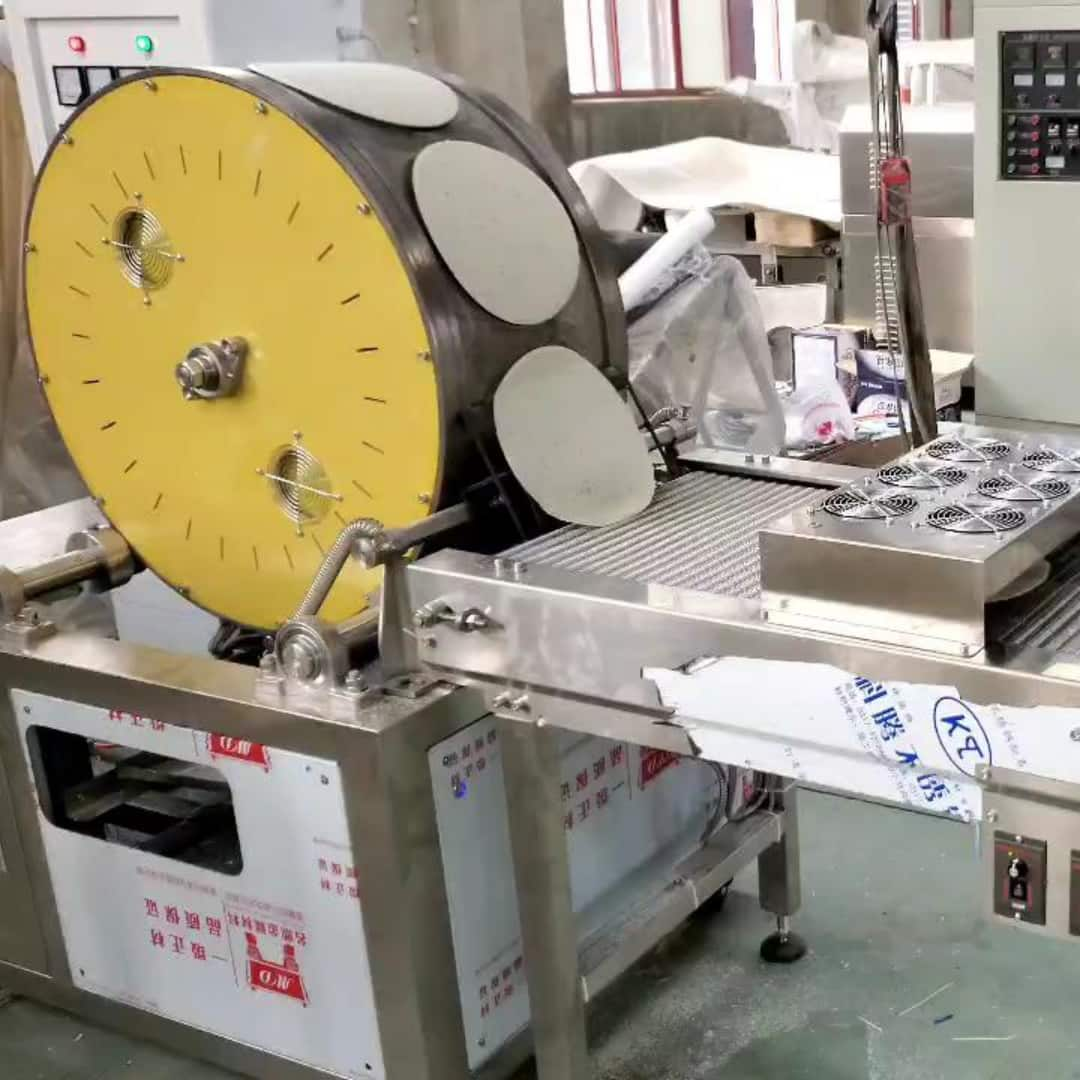

А Спринг -рулон is a food processing machine designed to produce thin, круглый, and uniform pastry sheets (обертки) used for making spring rolls, samosas, dumplings, и другие подобные закуски. Traditionally, making these wrappers by hand requires skill, time, и последовательность. A machine automates the process, allowing high-volume production with minimal labor.

The machine is widely used in:

- Фабрики по обработке пищевых продуктов

- Frozen food suppliers

- Hotels and restaurants with high demand

- Catering businesses

With this machine, businesses can meet increasing consumer demand while maintaining quality standards.

Why Invest in a Spring Roll Wrapper Making Machine?

Purchasing a Спринг -рулон is more than just an equipment upgrade—it’s an investment in efficiency and scalability. Here are some reasons why food businesses are making the switch:

- Стабильность качества

Hand-made wrappers often vary in thickness and size, which can affect the final product. A machine guarantees uniformity. - Высокая производственная мощность

В зависимости от модели, machines can produce hundreds to thousands of wrappers per hour. - Labor Cost Savings

Manual wrapper production is labor-intensive. A machine reduces the need for extra staff. - Гигиена и безопасность пищевых продуктов

The machine minimizes direct hand contact, ensuring compliance with food safety regulations. - Универсальность

Apart from spring rolls, the machine can produce samosa sheets, lumpia wrappers, dumpling skins, and even crepes.

How Does a Spring Roll Wrapper Machine Work?

Понимание working principle of a spring roll wrapper machine helps businesses operate it efficiently.

- Приготовление теста

Мука, вода, and sometimes starch are mixed to form a smooth, lump-free batter. - Automatic Feeding System

The batter is pumped into the machine’s spreading system. - Обогрев & Выпечка

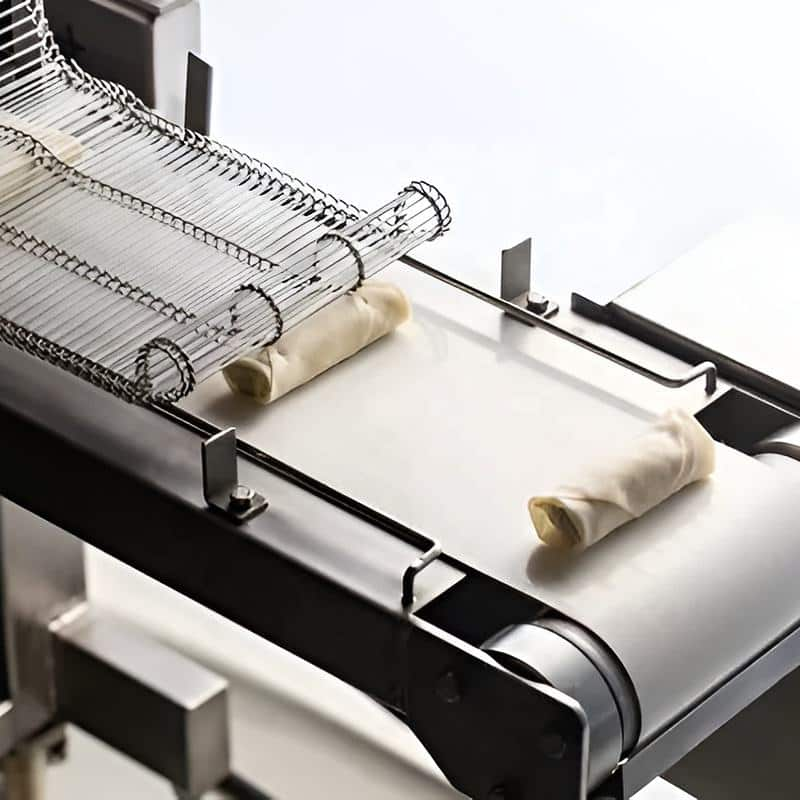

The batter is spread evenly onto a heated rotating drum or plate. В течение нескольких секунд, it forms a thin cooked sheet. - Резка & Формирование

The sheet is automatically cut into desired shapes—round, квадрат, or rectangular—depending on production needs. - Укладка & Counting

Finished wrappers are stacked and counted automatically, ready for packing or immediate use.

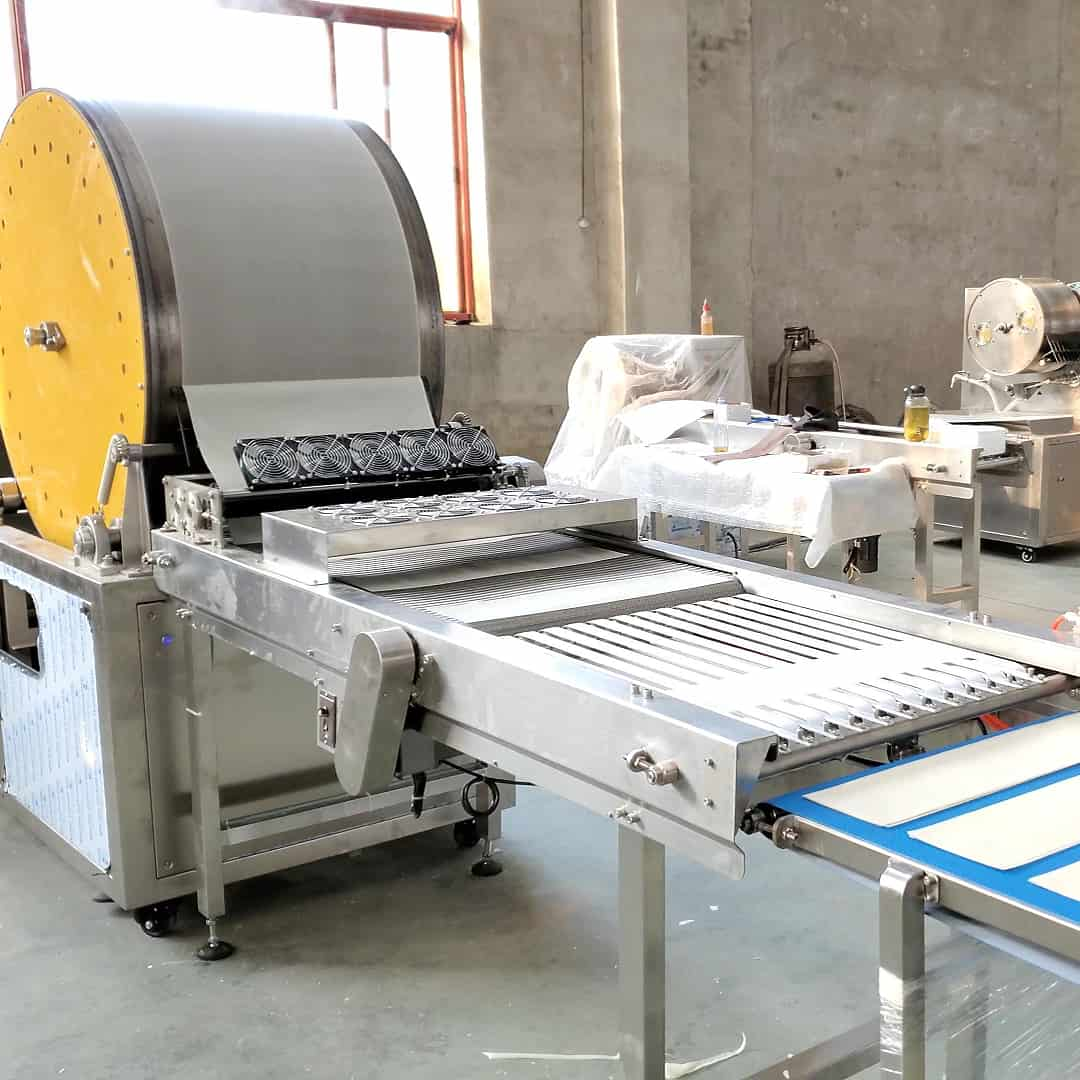

Key Features of Automatic Spring Roll Wrapper Machine

Современный автоматические машины для упаковки блинчиков с начинкой come with advanced technology that ensures user-friendly operation and maximum output. Some features include:

- Строительство нержавеющей стали (продовольственный, rust-resistant, Легко чистить)

- Adjustable Wrapper Thickness (usually 0.3mm–1.2mm)

- Multiple Shape Options (круглый, квадрат, прямоугольник)

- Система контроля температуры (precise heating for uniform cooking)

- Automatic Cutting & Укладка

- Энергоэффективность (optimized heating system reduces power consumption)

Technical Parameters of Spring Roll Wrapper Machine

Below is a general таблица технических параметров for a commercial spring roll wrapper machine:

| Модель | Емкость (шт/час) | Wrapper Size (мм) | Толщина оболочки (мм) | Власть (кВт) | Размеры (мм) | Масса (кг) |

|---|---|---|---|---|---|---|

| SRW-300 | 3000 | 100–200 | 0.3–1.0 | 6.5 | 1200×800×1300 | 350 |

| SRW-600 | 6000 | 100–220 | 0.3–1.2 | 9.0 | 1500×1000×1500 | 500 |

| SRW-1000 | 10,000 | 100–250 | 0.3–1.2 | 12.5 | 1800×1200×1600 | 750 |

Примечание: Specifications may vary depending on manufacturer and customization needs.

Types of Spring Roll Wrapper Machines

There are different models depending on production scale and business requirements:

1. Small Scale Spring Roll Wrapper Machine

Идеально подходит для ресторанов, small catering services, или стартапы. Компактный, простой в использовании, и доступный.

2. Semi-Automatic Spring Roll Wrapper Machine

Requires manual assistance in some steps, suitable for medium-scale production.

3. Fully Automatic Spring Roll Wrapper Machine

Handles the entire process—feeding, выпечка, резка, and stacking—ideal for food factories with high output demand.

Advantages of Fully Automatic Spring Roll Wrapper Machine

- One-person Operation – Easy to manage with minimal staff.

- High Speed & Эффективность – Can produce thousands of wrappers per hour.

- Параметры настройки – Adjustable size, толщина, and shape.

- Долговечность – Long lifespan with stainless steel body.

- Возврат инвестиций – Faster payback due to labor savings and higher production.

Applications of Spring Roll Wrapper Making Machine

Apart from spring rolls, тот wrapper machine can also produce:

- Samosa Sheets

- Lumpia Wrappers

- Dumpling Skins

- Wonton Wrappers

- Crepes or Pancakes

This versatility makes it a must-have for businesses in the frozen food and snack industry.

Spring Roll Wrapper Machine Price: Factors to Consider

The price of spring roll wrapper machine зависит от нескольких факторов:

- Производственные мощности – Higher capacity machines are more expensive.

- Уровень автоматизации – Fully automatic models cost more than semi-automatic ones.

- Материал & Качество сборки – Stainless steel construction increases durability but also cost.

- Параметры настройки – Specialized shapes, размеры, or functions affect pricing.

On average, small models may cost around $3,000–$8000, while fully automatic large-scale machines range between $15,000–$50,000 depending on specifications.

How to Choose the Best Spring Roll Wrapper Machine

При выборе а spring roll pastry sheet machine, Рассмотрим следующее:

- Production Needs – Small, середина, or industrial capacity.

- Доступность пространства – Ensure the machine fits your production area.

- Простота использования – Look for user-friendly controls.

- Послепродажная служба – Reliable suppliers provide installation, обучение, and maintenance support.

- Энергоэффективность – Save on electricity costs with advanced heating systems.

Installation and Maintenance Tips

- Place the machine on a flat, стабильная поверхность.

- Ensure proper electrical connections according to specifications.

- Clean the machine thoroughly after each production shift.

- Regularly check heating plates and conveyor belts for wear.

- Lubricate moving parts as recommended by the manufacturer.

При правильном уходе, а Спринг -рулон can last 8–10 years or more.

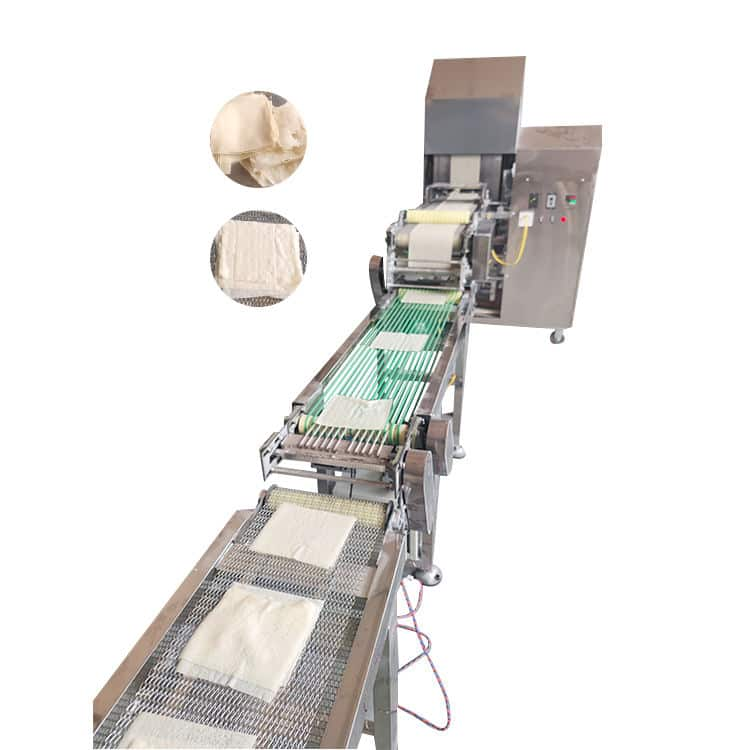

Spring Roll Wrapper Machine for Food Factories

Food factories that produce frozen snacks in bulk can benefit greatly from a fully automatic spring roll wrapper machine. Combined with freezing, упаковка, and sealing machines, it can form a complete spring roll production line, reducing costs and increasing output efficiency.

Spring Roll Wrapper Production Line

For large-scale manufacturers, а Производственная линия пружинной рулона может включать в себя:

- Dough Mixing Machine

- Automatic Wrapper Machine

- Заполняющий машины (optional for automatic spring roll making)

- Frying or Freezing Machine

- Упаковочная машина

This integrated line helps businesses scale to thousands of spring rolls per day.

Why Choose Us as Your Spring Roll Wrapper Machine Supplier?

- Над 20 многолетний опыт in food processing machinery

- Customizable solutions to fit your business needs

- Высококачественная конструкция из нержавеющей стали для долговечности

- Competitive factory-direct prices

- Global delivery and installation support

Часто задаваемые вопросы (Часто задаваемые вопросы)

1. Can the machine make different sizes of wrappers?

Да, most machines allow adjustment of wrapper diameter and thickness.

2. Is it difficult to operate?

Нет. With basic training, one person can operate it easily.

3. Can I use the machine for dumpling or samosa wrappers?

Да, with small adjustments, the machine can produce multiple types of sheets.

4. How long does shipping and installation take?

Usually 2–6 weeks depending on location and model.

5. Какой гарантийный срок?

Most machines come with a 1–2 year warranty.

For Future

А Спринг -рулон is a game-changer for food businesses aiming to produce high-quality wrappers at scale. Whether you run a small restaurant or a large frozen food factory, investing in the right machine ensures consistent product quality, cost savings, and higher profits.

By choosing a reliable manufacturer, you not only get a machine but also a long-term partner in your food production journey.

If you are ready to upgrade your business with a Спринг -рулон, contact us today for a tailored solution.