1. Знакомство с упаковочными машинами для спагетти

В быстрорастущей отрасли макаронных изделий, эффективность и точность определяют прибыльность. А упаковочная машина для спагетти является жизненно важной частью любой современной линии по производству макаронных изделий., предназначен для автоматизации взвешивания, наполнение, запечатывание, и процесс упаковки в пакеты длинных макаронных изделий, таких как спагетти., лингвини, и вермишель.

Для производителей макаронных изделий, право оборудование для упаковки спагетти не только повышает производительность, но и обеспечивает гигиену продукции, точный контроль веса, и привлекательная розничная презентация. От небольших мастерских до промышленных макаронных фабрик, анонца автоматическая машина для упаковки спагетти может значительно сократить ручной труд и эксплуатационные затраты.

2. Что такое упаковочная машина для спагетти?

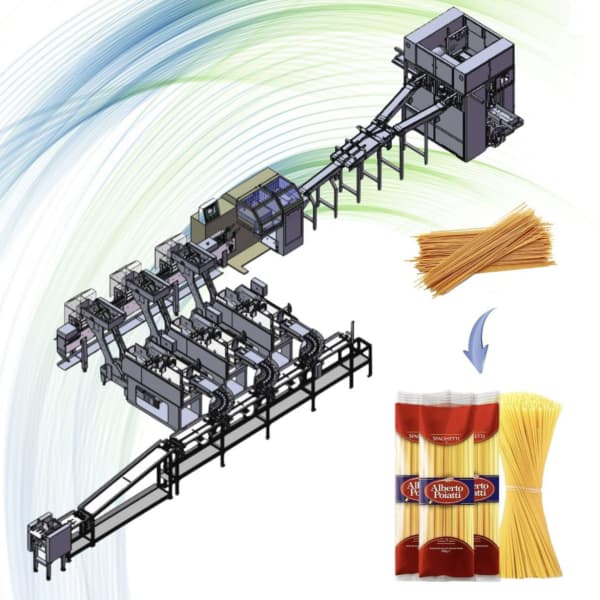

А упаковочная машина для спагетти специализированная автоматическая система для обработки длинных макаронных изделий. Процесс обычно включает в себя:

- Взвешивание: Точно отмеряем порции макарон.

- Объединение: Выравнивание прядей спагетти в аккуратные пучки.

- Упаковка или формирование пакета: Создание пакета из пленки или использование готовых пакетов..

- Наполнение и герметизация: Заполнение упаковки и запечатывание ее для сохранения свежести.

- Маркировка и резка: Печать сроков годности или номеров партий, обрезка по длине.

Современные машины оснащены передовыми датчиками, серводвигатели, и системы управления ПЛК для обеспечения стабильной работы и высокой скорости работы.. Некоторые из них являются частью полного линия упаковки спагетти, беспрепятственное подключение к расположенным выше сушильным и охлаждающим установкам и последующим системам упаковки в картонные коробки.

3. Зачем инвестировать в автоматическую упаковочную машину для спагетти?

3.1 Эффективность и производительность

Ручная упаковка требует много времени и непоследовательна.. С автоматическая машина для упаковки спагетти, операторы могут упаковывать сотни килограммов в час. Усовершенствованные модели достигают 30–60 упаковок в минуту, в зависимости от длины изделия и упаковочного материала.

3.2 Точность и сокращение отходов

Оснащен интеллектуальными системами взвешивания., машина гарантирует, что каждая упаковка соответствует точному весу — обычно 250 глин, 500 глин, или 1 кг — минимизация перелива или отходов продукта.

3.3 Гигиена и безопасность пищевых продуктов

Сделано из Айси 304 или 316 нержавеющая сталь, Оборудование для упаковки спагетти соответствует международным стандартам безопасности пищевых продуктов (HACCP, CE, FDA). Полностью закрытая конструкция защищает макароны от загрязнения..

3.4 Гибкость для разных типов упаковки

Упаковываете ли вы длинноразрезанные спагетти в пакетах-подушках, пачки в термоусадочной пленке, или коробки, машину можно настроить для различных форматов и упаковочных материалов, таких как полипропилен. (ПП), полиэтилен (ЧП), или рулоны композитной пленки.

3.5 Экономия стоимости

Хотя первоначальные инвестиции могут показаться высокими, автоматизация значительно снижает затраты на рабочую силу и уменьшает количество человеческих ошибок. Через некоторое время, тот возврат инвестиций (Рентабельность) имеет большое значение для крупных производителей.

4. Основные компоненты и принцип работы

Высококачественное машина для взвешивания и запечатывания спагетти обычно включает в себя следующие модули:

| Компонент | Функция |

|---|---|

| Питающий конвейер | Транспортирует спагетти с линии сушки на участок упаковки.. |

| Вибрационное выравнивающее устройство | Равномерно выравнивает пряди спагетти перед укладкой в пучок.. |

| Весовой блок | Измеряет точный вес пакета с помощью датчиков или датчиков веса.. |

| Система размотки пленки | Подает упаковочную пленку в формовочную трубу.. |

| Блок формирования пакетов | Сворачивает пленку в трубочку и запечатывает один конец, образуя пакет.. |

| Раздел наполнения | Вкладывает пачки спагетти в сформированный пакет.. |

| Запечатывание & Режущий блок | Термосваривает верхнюю часть пакета и обрезает его по длине.. |

| Кодирование & Маркировочное устройство | Печатает коды даты или этикетки. |

| Выходной конвейер | Передаёт готовые мешки на следующий процесс (картонная упаковка). |

Большинство автоматические машины для упаковки спагетти в пакеты использовать ПЛК + сенсорный экран (HMI) интерфейсы, позволяя операторам настраивать такие параметры, как скорость, длина сумки, температура уплотнения, и вес упаковки с легкостью.

5. Технические характеристики (Пример)

Ниже приведен пример таблицы технических характеристик промышленного оборудования. линия упаковки спагетти:

| Параметр | Спецификация |

|---|---|

| Модель | ДТ-СП600 |

| Тип продукта | Длинные макароны (Спагетти, Лингвини, Вермишель) |

| Вес упаковки | 250 г – 1000 глин |

| Длина сумки | 200 мм – 500 мм |

| Скорость упаковки | 30–60 упаковок/мин |

| Материал пленки | ОПП/КПП, ПЭТ/ПЭ, БОПП/КПФ, и т. д.. |

| Источник питания | 380 В / 50 Гц / 3 Фаза |

| Общая мощность | 4.5 кВт |

| Машино -измерение | 3800 мм × 1200 мм × 2000 мм |

| Вес машины | 850 кг |

| Материал | ИХ 304 Нержавеющая сталь |

| Система управления | ПЛК + Сенсорный экран |

| Давление воздуха | 0.6 МПа |

Эти параметры могут быть настроены в зависимости от производственной мощности и формата упаковки..

6. Ключевые слова и приложения с длинным хвостом

А упаковочная машина для спагетти является частью более широкой семьи системы упаковки макаронных изделий, который также включает в себя:

- Автоматическая машина для взвешивания и фасовки макаронных изделий

- Оборудование для упаковки длиннорезаных макарон в пакеты

- Промышленная машина для упаковки спагетти в пакеты

- Машина для упаковки спагетти в флоу-пленку

- Машина для запечатывания и резки спагетти-пленки

- Высокоскоростная система упаковки макаронных изделий

- Автоматическая машина для упаковки спагетти

- Машина для запечатывания пакетов для спагетти

Эти машины широко используются в промышленные макаронные фабрики, компании по упаковке пищевых продуктов, и контрактные производственные предприятия.

Они также могут обрабатывать аналогичные продукты, такие как лингвини, феттучини, вермишель, и рисовая лапша с минимальной регулировкой.

7. Параметры настройки

При выборе линия упаковки спагетти, производители часто запрашивают индивидуальные конфигурации. Некоторые доступные настройки включают в себя:

- Длина пачки & регулировка диаметра: 200Варианты длины спагетти –500 мм.

- Совместимость типов пленки: Ламинированная пленка, термоусадочная пленка, перерабатываемые упаковочные материалы.

- Многовесовая упаковка: 250 g розничные упаковки или 5 мешки для еды кг..

- Интегрированная маркировка & печать штрих-кода.

- Системы паллетирования в конце линии для крупных заводов.

- Системы автоматического переключения для быстрого переключения типа продукта.

Пищевая машина ДТ, например, предложения полные индивидуальные решения для упаковки спагетти интегрированное взвешивание, наполнение, упаковка в мешки, и маркировка — все в одной строке.

8. Интеграция с линией по производству макаронных изделий

А упаковочная машина для спагетти обычно подключается после установка для сушки и охлаждения макаронных изделий. Интегрированный рабочий процесс может выглядеть так:

- Экструзия: Тесто для макарон раскатывается в длинные пряди..

- Резка & Сушка: Пряди состригаются до стандартной длины спагетти и сушатся..

- Охлаждение & Выравнивание: Высушенные спагетти охлаждают и складывают в связки..

- Автоматическая подача: Пачки автоматически передаются на упаковочную линию..

- Взвешивание & Упаковка: Спагетти взвешивают и упаковывают в пакеты..

- Запечатывание & Маркировка: Мешки запечатываются и маркируются с информацией о производстве..

- Картонирование & Паллетирование: Готовые упаковки упаковываются в картонные коробки для отправки..

Эта бесшовная интеграция обеспечивает непрерывный, гигиеничный, и эффективное производство— имеет решающее значение для поддержания качества и срока годности макаронных изделий..

9. Как правильно выбрать оборудование для упаковки спагетти

Выбор лучшего упаковочная машина для спагетти зависит от ваших производственных потребностей. Учитывайте следующие факторы:

9.1 Объем производства

Если вы упаковываете небольшие партии, полуавтоматической модели может быть достаточно. Для промышленного производства, выбрать Полностью автоматическая высокоскоростная линия упаковки спагетти.

9.2 Тип упаковки

Вы предпочитаете сумки-подушки?, пачки в термоусадочной пленке, или картонные коробки? Каждый формат требует специального оборудования..

9.3 Пространство и планировка

Проверьте планировку вашего завода. Машины для производства макаронных изделий длинной нарезки требуют достаточно места для конвейеров и систем выравнивания пачек..

9.4 Техническая поддержка

Выберите поставщика, предлагающего установку, Обучение оператора, и послепродажная поддержка. Такие бренды, как Пищевая машина ДТ обеспечить глобальное техническое обслуживание и доступность запасных частей.

9.5 Бюджет и рентабельность инвестиций

Хотя стоимость машин варьируется (от долларов США 15,000 к 60,000+ в зависимости от конфигурации), автоматизация быстро окупается за счет экономии труда и эффективности.

10. Советы по обслуживанию и безопасности

Поддержание вашего оборудование для упаковки спагетти обеспечивает долговечность и безопасность пищевых продуктов:

- Регулярно очищайте уплотнительные губки и конвейеры, чтобы предотвратить загрязнение..

- Проверьте датчики и тензодатчики на предмет точности взвешивания..

- Своевременно заменяйте изношенные ремни или уплотнительные элементы..

- Часто проверяйте натяжение и выравнивание пленки..

- Соблюдайте процедуры безопасности: аварийная остановка, блокировочные ограждения, и обучение операторов.

График профилактического технического обслуживания может продлить срок службы машины за пределы 10 лет стабильной работы.

11. Почему стоит выбрать DT Food Machine в качестве партнера по упаковке спагетти

Пищевая машина ДТ специализируется на индивидуальные решения по переработке и упаковке макаронных изделий для клиентов по всему миру. Имея более чем десятилетний опыт, ДТ предоставляет:

- Под ключ линии по производству и упаковке спагетти

- Оборудование, сертифицированное CE и ISO

- Индивидуальные конфигурации для макаронных изделий различной формы и производительности.

- Монтаж и послепродажное обслуживание по всей Азии., Европа, и Латинская Америка

- Энергоэффективный, высокоскоростной, и прочные конструкции

Сотрудничая с DT Food Machine, вы получаете не только надежное оборудование, но и профессиональную техническую команду, которая поможет при установке, обучение, и постоянное улучшение.

12. Запросить предложение (RFQ)

Если вы планируете модернизировать упаковочную линию или построить новую фабрику по производству макаронных изделий, свяжитесь с DT Food Machine для индивидуальное предложение.

Пожалуйста, включите:

- Тип пасты (например, спагетти, лингвини, феттучини)

- Вес и формат упаковки

- Целевая мощность (упаковок/час или кг/день)

- Предпочтительный упаковочный материал (фильм, сумка, коробка)

- Информация о напряжении и заводской компоновке

Электронная почта: info@dtfoodmachine.com

Веб-сайт: www.dtfoodmachine.com

13. Упаковочная машина для спагетти

Макаронная отрасль развивается быстрыми темпами., автоматизация больше не является необязательной — она необходима. А упаковочная машина для спагетти оптимизирует операции, повышает качество продукции, и увеличивает прибыльность.

От автоматические машины для взвешивания и запечатывания спагетти к комплексные системы упаковки макаронных изделий, современные технологии позволяют производить стабильное, привлекательный, и безопасные упаковки для макарон, соответствующие международным рыночным стандартам..

Благодаря инновационным решениям от Пищевая машина ДТ, вы можете поднять свою линию по производству спагетти на новый уровень эффективности, точный, и создан для долгосрочного успеха.