Введение в машину для изготовления блинов

А Машина для изготовления блинов это профессиональное оборудование для пищевой промышленности, предназначенное для эффективного производства блинов., последовательно, и гигиенично. Блинчики, известен своей тонкой текстурой и универсальностью, популярны в кафе, уличные ларьки с едой, магазины десертов, рестораны быстрого питания, отели, и промышленные пищевые заводы по всему миру. Поскольку потребительский спрос продолжает расти, ручное производство блинов уже недостаточно для предприятий, требующих высокой производительности, стандартизированное качество, и экономическая эффективность.

Вот где коммерческая машина для изготовления блинов, автоматическая блинница, и промышленная машина для изготовления блинов стать важными инструментами. Эти машины помогают предприятиям повысить производительность, сократить трудозатраты, и доставляйте блины однородной формы в больших масштабах.

Что такое машина для изготовления блинов?

А Машина для изготовления блинов специализированное пищевое оборудование, автоматизирующее процесс выкладывания теста, обогрев, приготовление пищи, и иногда переворачиваю блины. В зависимости от уровня автоматизации, оно может варьироваться от полуавтоматические электрические блинные машины к полностью автоматические промышленные линии по производству блинов.

Общие альтернативные имена и ключевые слова с длинным хвостом включают::

- Автоматическая машина для изготовления блинов

- Коммерческая блинная машина

- Электрическая блинница для бизнеса

- Промышленная блинная машина

- Машина для производства блинов

- Профессиональная блинница

- Машина для приготовления блинов

Все эти термины относятся к оборудованию, предназначенному для производства блинов постоянной толщины., размер, и текстура.

Как работает машина для изготовления блинов?

Рабочий процесс А. Машина для изготовления блинов простой, но очень эффективный:

- Подача теста

Тесто для блинов заливается вручную или автоматически подается в машину через бункер или систему дозирования.. - Распределение теста

Вращающийся барабан, разбрасывающий валик, или плоская нагревательная пластина равномерно распределяет тесто тонким круглым слоем.. - Отопление и приготовление пищи

Машина использует электрический или газовый нагрев для приготовления блинов при контролируемой температуре.. - Переворачивание или пилинг

В зависимости от модели, блин можно автоматически перевернуть или снять с барабана после приготовления. - Охлаждение и сбор

Готовые блины собираются вручную или передаются на конвейер для охлаждения и упаковки..

Этот автоматизированный процесс обеспечивает равномерное приготовление., стабильный выход, и высокие стандарты безопасности пищевых продуктов.

Типы машин для изготовления блинов

1. Ручная и полуавтоматическая машина для изготовления блинов

А полуавтоматическая машина для изготовления блинов обычно требует ручной разливки теста и удаления блинов, но автоматизирует нагрев и распространение. Эти машины идеально подходят для:

- Маленькие кафе

- Продовольственные грузовики

- Продавцы уличной еды

- Стартап-бизнес

Они компактны, простой в эксплуатации, и доступный.

2. Коммерческая машина для изготовления блинов

А коммерческая машина для изготовления блинов предназначен для непрерывного ежедневного использования. Он предлагает:

- Более высокая выходная мощность

- Прочные пищевые материалы.

- Точный контроль температуры

- Стабильная производительность

Этот тип блинница для бизнеса обычно используется в ресторанах, десертные цепочки, и торговые центры.

3. Полностью автоматическая машина для изготовления блинов

А полностью автоматическая машина для изготовления блинов интегрирует подачу теста, распространение, приготовление пищи, и сброс в одну систему. Преимущества включают в себя:

- Минимальная потребность в рабочей силе

- Высокая консистенция

- Непрерывное производство

- Подходит для блинов стандартного размера.

Эти машины идеально подходят для средних и крупных предприятий пищевой промышленности..

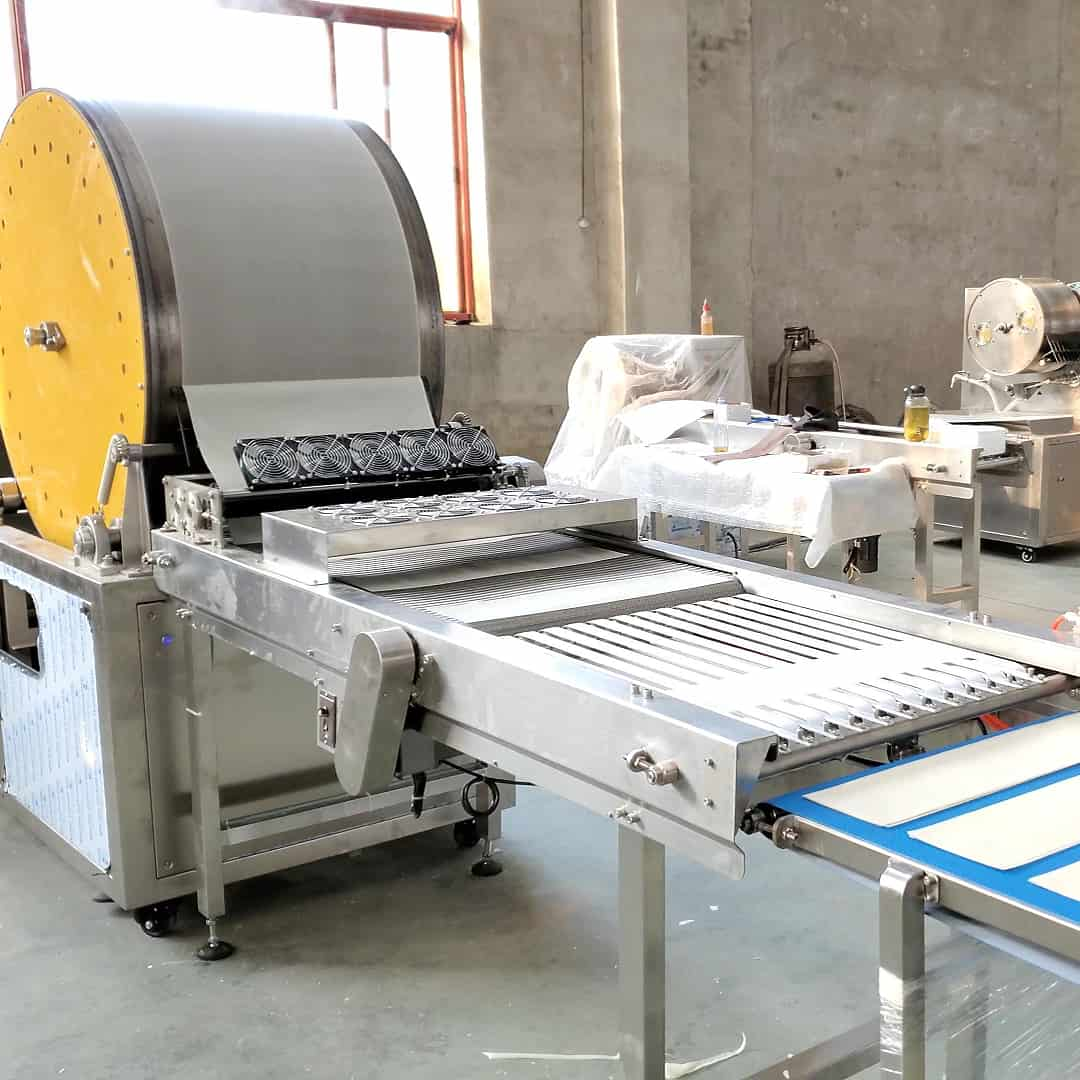

4. Промышленная машина для изготовления блинов

Анонца промышленная машина для изготовления блинов предназначен для крупных производств и пищевых предприятий. Часто это работает как часть линия по производству блинов и может быть интегрирован с системой охлаждения, штабелирование, и системы упаковки.

Ключевые особенности включают в себя:

- Высокая выходная мощность

- Система управления ПЛК

- Непрерывное приготовление в барабане

- Легкая очистка и обслуживание

Основные характеристики машины для изготовления блинов

Высококачественное Машина для изготовления блинов обычно включает в себя следующие функции:

- Конструкция из пищевой нержавеющей стали

- Точный контроль температуры

- Равномерная система распределения теста

- Варочная поверхность с антипригарным покрытием

- Энергоэффективное отопление

- Стабильная и безопасная работа

- Легкая очистка и обслуживание

Усовершенствованные модели могут также включать:

- Управление сенсорным экраном ПЛК

- Регулируемая толщина крепа

- Регулируемый диаметр

- Автоматическая система штабелирования

Применение машины для изготовления блинов

The Машина для изготовления блинов имеет широкий спектр применения в различных отраслях промышленности:

Пищевая промышленность

- Кафе и пекарни

- Магазины десертов

- Рестораны быстрого питания

- Отели и курорты

Уличная еда и розничная торговля

- Продовольственные грузовики

- Ночные рынки

- Киоски торговых центров

Пищевая промышленность

- Производство замороженных блинов

- Готовая к употреблению упаковка для крепов

- Центральные кухни

- Кейтеринговые компании

Потому что блины могут быть сладкими или солеными, тот коммерческая блинная машина поддерживает разнообразные варианты меню.

Преимущества использования машины для изготовления блинов

1. Более высокая эффективность производства

По сравнению с приготовлением вручную, а машина для изготовления блинов значительно увеличивает производительность и скорость.

2. Последовательное качество продукта

Автоматизированная температура и распределение обеспечивают однородную толщину и текстуру крепа..

3. Снижение затрат на рабочую силу

Один оператор может управлять несколькими машинами, снижение расходов на персонал.

4. Улучшенная безопасность пищевых продуктов

Пищевые материалы и контролируемые процессы соответствуют гигиеническим стандартам..

5. Масштабируемость для роста бизнеса

От небольших магазинов до промышленных предприятий, блинные машины поддерживают масштабируемое производство.

Машина для изготовления блинов и ручное приготовление блинов

| Аспект | Ручное приготовление блинов | Машина для изготовления блинов |

|---|---|---|

| Выход | Низкий | Высокий |

| Последовательность | Нестабильный | Униформа |

| Стоимость рабочей силы | Высокий | Низкий |

| Гигиена | Зависит от оператора | Контролируемый |

| Масштабируемость | Ограничен | Отличный |

Это сравнение ясно показывает, почему предприятия предпочитают коммерческая или промышленная машина для изготовления блинов.

Как правильно выбрать машину для изготовления блинов

При выборе а Машина для изготовления блинов, Рассмотрим следующие факторы:

Производственные мощности

Определите, сколько блинов в час требуется вашему бизнесу.

Уровень автоматизации

Выбирайте между полуавтоматом., автоматический, или промышленные машины.

Источник питания

Электрические машины для изготовления блинов чище и проще в управлении, в то время как газовые модели могут снизить эксплуатационные расходы в некоторых регионах.

Размер и толщина крепа

Убедитесь, что машина поддерживает желаемый диаметр и толщину блинов..

Послепродажная поддержка

Надежная техническая поддержка и наличие запасных частей имеют решающее значение..

Техническое обслуживание и очистка машины для изготовления блинов

Правильное обслуживание обеспечивает длительный срок службы и стабильную работу.:

- Ежедневно очищайте варочную поверхность

- Регулярно проверяйте нагревательные элементы

- Осмотр электрических компонентов

- При необходимости смажьте движущиеся части.

- Следуйте рекомендациям производителя

Ухоженный машина для изготовления блинов может эффективно работать в течение многих лет.

Тенденции рынка машин для изготовления блинов

Мировой рынок для Машины для изготовления блинов растет из-за:

- Растущий спрос на уличную еду

- Расширение десертных сетей

- Рост автоматизации пищевой промышленности

- Рост рынков замороженных и готовых к употреблению продуктов питания

Будущие тенденции включают в себя:

- Умные системы управления

- Энергосберегающие конструкции

- Компактные многофункциональные машины

- Интеграция с упаковочными линиями

Общие часто задаваемые вопросы о машине для изготовления блинов

Проста ли в эксплуатации машина для изготовления блинов??

Да, большинство машин предназначены для простой эксплуатации с минимальной подготовкой.

Может ли одна машина производить разные виды блинов?

Да, корректируя рецепты и настройки теста.

Подходит ли автоматическая машина для изготовления блинов для малого бизнеса?

Абсолютно. Многие компактные автоматические модели идеально подходят для стартапов..

Зачем инвестировать в машину для изготовления блинов?

А Машина для изготовления блинов это разумная инвестиция для любого бизнеса, занимающегося производством блинов. Независимо от того, управляете ли вы небольшим кафе или крупной пищевой фабрикой, используя коммерческая или промышленная машина для изготовления блинов помогает вам повысить эффективность, Обеспечить последовательное качество, сократить трудозатраты, и успешно масштабируйте свой бизнес.

С ростом популярности блинов во всем мире, выбор правильного автоматическая машина для изготовления блинов может дать вашему бизнесу сильное конкурентное преимущество и долгосрочную прибыльность.