Введение: Революция в производстве печенья

Мировой спрос на высококачественное печенье постоянно растет., обусловлено предпочтением потребителей к удобному, вкусный, и доступные закуски. Чтобы удовлетворить этот растущий спрос, обеспечивая при этом последовательность, гигиена, и эффективность, а полностью автоматическая линия по производству печенья стал золотым стандартом в промышленном производстве продуктов питания.

В данной статье представлен комплексный обзор современной линия по производству печенья, подробное описание используемого оборудования, производственный поток, Технические спецификации, функции автоматизации, и бизнес-преимущества для бисквитных фабрик по всему миру.

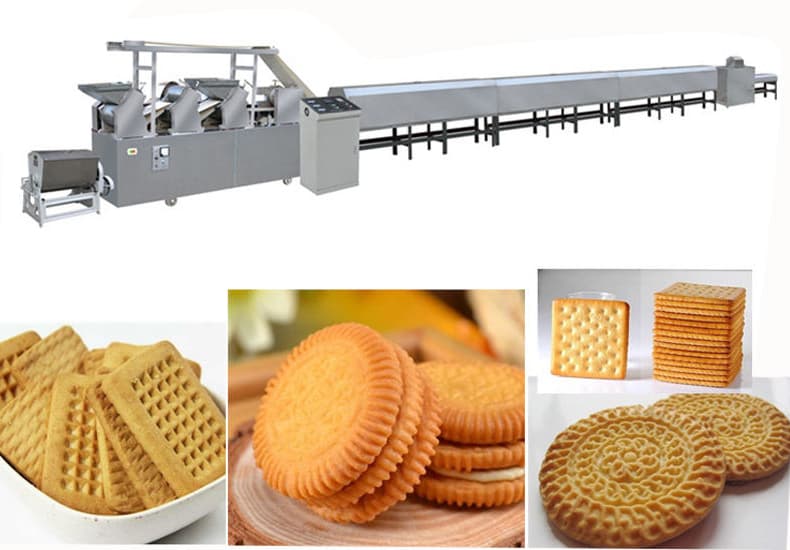

1. Что такое полностью автоматическая линия по производству печенья?

А полностью автоматическая линия по производству печенья представляет собой интегрированную систему оборудования, предназначенную для переработки сырья в готовые, фасованное печенье с помощью автоматизированных операций. Это устраняет необходимость ручного труда на различных этапах, таких как смешивание., формирование, выпечка, охлаждение, и упаковка.

От классического сдобного печенья до печенья-сэндвича с кремовой начинкой., эта производственная линия позволяет производить широкий спектр типов продукции с высокой точностью и минимальными отходами..

2. Ключевые компоненты линии по производству печенья

Профессионал линия по производству печенья состоит из следующего основного оборудования:

2.1 Тесто миксер

- Смешивает муку, толстый, вода, сахар, и добавок замесить однородное тесто.

- Параметры: Горизонтальный смеситель, вертикальный спиральный смеситель.

2.2 Конвейер подачи теста

- Переносит тесто в формовочную машину..

- Регулируемая скорость, конструкция из нержавеющей стали..

2.3 Машина для формования печенья

- Типы: Ротационная формовочная машина, роторный резак, перерезка проволоки, или экструдер.

- Изготовленные на заказ формы для печенья различной формы и рисунка..

2.4 Туннельная печь для выпечки

- Источник тепла: Электрический, газ, дизель, или инфракрасный.

- Равномерное выпекание с температурными зонами для точного контроля..

2.5 Масляный распылитель (Необязательный)

- Наносит масло или глазурь для блеска и усиления вкуса..

2.6 Конвейер охлаждения печенья

- Снижает температуру выпечки печенья перед упаковкой..

- Обеспечивает твердость продукта и предотвращает образование конденсата..

2.7 Упаковочная линия

- Типы: Горизонтальная упаковочная машина, вертикальная форма-заполнение-уплотнение (VFFS).

- Функции: Кодирование даты, промывка азотом, приложение для этикеток.

3. Технические характеристики

| Параметр | Спецификация |

|---|---|

| Производственные мощности | 100 кг/ч до 2000 кг/ч |

| Поддерживаемые типы печенья | Твёрдое печенье, мягкое печенье, бутерброд, печенье |

| Длина духовки | 20м–60м (настраиваемый) |

| Источник тепла | Электрический / Газ / Дизель / сжиженный нефтяной газ |

| Требование к питанию | 50 кВт – 200 кВт (зависит от конфигурации) |

| Рабочее напряжение | 380V/50 Гц 3 Фаза (настраиваемый) |

| Система управления | ПЛК + HMI (сенсорная панель) |

| Материал | Пищевая зерна SUS304 нержавеющая сталь |

| Скорость формования | До 25–40 форм/мин. (в зависимости от типа) |

| Скорость упаковки | 20–120 упаковок/мин |

4. Схема производственного процесса

Шаг 1: Приготовление теста

Ингредиенты взвешиваются и смешиваются в автоматическом миксере..

Шаг 2: Транспортировка теста

Замешанное тесто передается в формовочную систему без контакта с человеком..

Шаг 3: Формирование печенья

Печенью придают форму с помощью ротационного резака или экструдера., формирование листов теста или отдельных печенек.

Шаг 4: Выпечка

Формованное печенье проходит через туннельную печь с несколькими температурными зонами..

Шаг 5: Охлаждение

Выпеченное печенье равномерно охлаждается с помощью вентиляторов конвейера, чтобы сохранить форму и текстуру..

Шаг 6: Упаковка

Печенье выровнено, посчитал, и упакованы в пакеты, подносы, или коробки автоматически.

5. Виды производимого печенья

А линия по производству печенья можем производить различные стили печенья, в том числе:

| Тип печенья | Описание |

|---|---|

| Твёрдое печенье | Низкое содержание сахара/жира, Хрустящая текстура (например, Мари, Газировка) |

| Мягкое печенье | Высокое содержание сахара/жира, мягкая текстура (например, песочное печенье) |

| Сэндвич-печенье со сливками | Два бисквита с кремовой начинкой |

| Файлы cookie | Толстый, жевательная текстура (часто образуются обрывы проволоки) |

| Вафельное печенье | Тонкие слои с кремовой начинкой. |

6. Автоматизация & Интеллектуальные функции

- Панель управления ПЛК – Мониторинг и корректировка параметров в режиме реального времени.

- Сенсорный экран ЧМИ – Удобный интерфейс для настройки рецептов.

- Датчики температуры – Многозонное регулирование температуры духовки..

- Сервомоторный привод – Для точного формирования и выравнивания печенья.

- Удаленное обслуживание (Необязательный) – Поддержка через облачное соединение IoT.

7. Преимущества полностью автоматической линии по производству печенья

✅ 1. Повышенная эффективность

Непрерывный, высокоскоростное производство с минимальными простоями.

✅ 2. Последовательное качество продукта

Точная дозировка ингредиентов., формирование, и выпечка гарантирует, что каждое печенье будет однородным.

✅ 3. Сокращение затрат на рабочую силу

Полностью автоматизированная работа радикально сокращает потребность в ручном труде..

✅ 4. Гигиена и безопасность

Закрытая обработка на оборудовании из пищевой нержавеющей стали соответствует стандартам HACCP и GMP..

✅ 5. Оптимизация энергопотребления

Современные печи и конвейеры разработаны с учетом энергоэффективности..

8. Рассмотрение планировки завода

Бисквитную фабрику необходимо проектировать исходя из:

- Производственная мощность

- Помещения для хранения сырья и готовой продукции

- Зоны вентиляции и теплоизоляции

- Отдельные зоны для теста, выпечка, охлаждение, и упаковка

- Наличие электро- и водоснабжения

Типичная планировка может варьироваться от 25 метров до более 100 метров в длину в зависимости от мощности и вида печенья.

9. Тематическое исследование: 1000 кг/ч Линия по производству печенья

Клиент: Производитель закусок в Юго-Восточной Азии

Основные моменты настройки:

- 60-газовая духовка по счетчику

- Двойные вращающиеся ножи для изменения формы.

- Азотозаполненная горизонтальная упаковочная машина

- 24/7 операция, три смены

Исход:

- Производство увеличилось в 4 раза

- Количество отходов сократилось на 35%

- Окупаемость инвестиций достигнута в 14 месяцы

10. Распространенные вопросы покупателей (Раздел запросов цен)

Q1: Какова минимальная доступная мощность?

А: Наша самая маленькая линия по производству печенья начинается в 100 кг/ч, идеально подходит для малых и средних предприятий.

Q2: Может ли производственная линия обрабатывать печенье различной формы??

А: Да, формы можно быстро заменить для поддержки различных форм и узоров..

Q3: Проводится ли обучение операторов?

А: Да, мы проводим очное или дистанционное обучение вашего персонала.

Q4: Может ли линия интегрироваться с существующим заводом??

А: Абсолютно. Мы настраиваем планировки в соответствии с существующей инфраструктурой..

Q5: Как долго длится доставка?

А: Стандартная доставка составляет 35–60 дней в зависимости от индивидуальных особенностей..

11. Техническое обслуживание и поддержка

- График профилактического обслуживания

Регулярные проверки подшипников, ремни, моторы, и датчики. - Доступность запасных частей

Быстрая доставка критически важных компонентов по всему миру. - Удаленная диагностика

Включается через промышленные маршрутизаторы и диагностику ПЛК..

12. Цены & Возврат инвестиций

| Емкость | Ориентировочная цена (доллар США) |

|---|---|

| 100–200 кг/ч | $35,000 - $60,000 |

| 300–500 кг/ч | $70,000 - $120,000 |

| 800–1000 кг/ч | $150,000 - $220,000 |

| 1500 кг/ч+ | $250,000 и выше |

Период окупаемости инвестиций: Обычно 12 к 24 месяцев в зависимости от масштаба и рыночных условий.

13. Рыночные тенденции & Перспективы на будущее

- Растущий спрос на более полезное печенье (низкий уровень сахара, не содержит глютен).

- Растущие инвестиции в умные фабрики и Промышленность 4.0.

- Расширение экспортных возможностей в Африке, Ближний Восток, и Латинская Америка.

14. Заключение: Создайте свою фабрику по производству печенья с уверенностью

Полностью автоматический линия по производству печенья дает производителям продуктов питания возможность поставлять высококачественную продукцию в больших масштабах и на постоянной основе, гигиена, и гибкость. Независимо от того, запускаете ли вы завод по производству печенья или модернизируете свое предприятие, инвестиции в современную технологию производства печенья – залог долгосрочной прибыльности.

Готов сделать следующий шаг? Свяжитесь с нами для получения индивидуального предложения, дизайн макета, и цитата.