Instant noodles are a global convenience food enjoyed in almost every country. The industry is worth billions of dollars annually, with steady demand from both developing and developed markets. For food entrepreneurs, building an linie de producție instant de tăiței is an excellent investment, but it requires careful planning, specialized equipment, și respectarea standardelor de siguranță alimentară.

We provides a comprehensive guide on how to set up an instant noodle factory, including market considerations, step-by-step process design, machine selection, Specificații tehnice, Analiza costurilor, and factory layout.

1. Global Market and Business Potential

1.1 Worldwide Demand for Instant Noodles

Potrivit World Instant Noodles Association, peste 120 miliarde de porții are consumed globally every year. Key markets include:

- China: Peste 40 billion servings annually.

- Indonezia: More than 12 miliarde de porții.

- Japonia, STATELE UNITE ALE AMERICII, and South Korea: Mature markets with steady demand.

- Africa and South America: Fast-growing markets due to urbanization.

1.2 Product Trends

- Non-fried instant noodles are increasing in popularity due to health concerns.

- Cupă cu tăiței are popular in urban markets with younger demographics.

- Premium instant noodles with unique flavors are trending in developed countries.

Takeaway: Before building a line, identify your target consumer base and decide whether you will produce fried block noodles, taitei neprajiti, or cup noodles.

2. Planning Your Instant Noodle Production Line

2.1 Determining Production Capacity

Production lines are typically categorized as:

- La scară mică: 1,000–10,000 packs/day, suitable for startups.

- La scară medie: 10,000–100,000 packs/day, good for regional distribution.

- La scară largă: 100,000+ pachete/zi, targeting nationwide or export markets.

2.2 Choosing Automation Level

- Linii semi-automate: Require more labor but cost less to install.

- Linii complet automate: High output, lower labor cost, but higher initial investment.

2.3 Space and Infrastructure Requirements

- Small plant: 500–800 m².

- Medium plant: 1,000-1.500 m².

- Large plant: 2,000+ m².

- Must include space for raw material storage, production line, ambalaj, quality control lab, and finished goods warehouse.

3. Step-by-Step Process of Instant Noodle Production

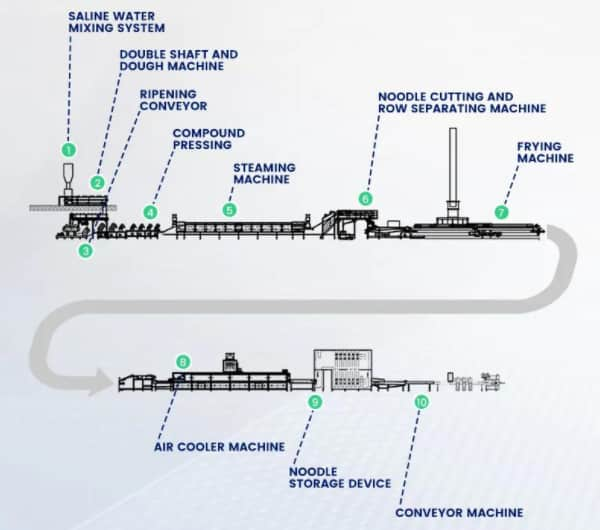

O completă linie de producție instant de tăiței follows these steps:

3.1 Amestecarea făinii

- Ingrediente: făină de grâu, apă, sare, apa alcalina (kansui), și aditivi.

- Maşină: Automatic flour mixer ensures uniform hydration.

3.2 Dough Sheeting

- Dough is compressed into sheets by a compound roller.

- Multiple rolling stages improve gluten structure and elasticity.

3.3 Cutting and Slitting

- Sheets are cut into thin strands using a slitter cutter.

- Noodles may be straight or wavy depending on cutter design.

3.4 Aburire

- Strands are steamed in a tunnel at 100–105°C.

- Gelatinization ensures proper texture after cooking.

3.5 Shaping and Cutting

- Noodles are folded and placed into molds or cups.

3.6 Frying or Drying

- Taitei prajiti: Dehydrated in edible oil at ~150°C for 1–2 minutes.

- Taitei neprajiti: Passed through a hot-air dryer at 70–90°C.

3.7 Răcire

- Essential for stabilizing product before packaging.

3.8 Ambalaj

- Bag noodles: Mașină de ambalat perne.

- Cupă cu tăiței: Cup sealing machine with seasoning sachet insertion…

4. Machinery and Technical Specifications

| Maşină | Funcţie | Capacitate | Putere | Dimensiuni | Note |

|---|---|---|---|---|---|

| Flour Mixer | Mix flour & apă | 200–500 kg/h | 4–7 kW | 1500×900×1200 mm | Oţel inoxidabil |

| Rolă compusă | Roll dough into sheets | 200–800 kg/h | 5-10 kW | 2000×1000×1500 mm | Grosime reglabilă |

| Slitter Cutter | Cut sheets into strands | 200–500 kg/h | 2–5 kW | 1200×800×1100 mm | Customizable width |

| Tunel abur | Steam strands | 200–1000 kg/h | 20–30 kW | 6000×1200×2200 mm | Controlul temperaturii |

| Friteuza | Fry noodles in oil | 200–1000 pcs/min | 25–45 kW | 7000×1600×2300 mm | Oil circulation |

| Dryer (neprajite) | Dry noodles | 200–800 kg/h | 30–50 kW | 9000×1800×2500 mm | Hot-air drying |

| Mașină de ambalare | Pack noodles | 30-120 pachete/min | 3–6 kW | 3500×900×1400 mm | Bag/cup options |

5. Utility Requirements

- Electricitate: Industrial 3-phase supply for high-power machines.

- Steam Boiler: Required for steaming and frying.

- Water Supply: Clean, filtered water for dough and cleaning.

- Ventilare & Exhaust: To remove oil fumes from frying section.

- Wastewater treatment: Required by food safety regulations.

6. Quality Control in Production

6.1 Materii prime

- Wheat flour must meet protein content standards.

- Palm oil should be food-grade and filtered regularly.

6.2 In-Process Control

- Dough moisture checked every batch.

- Steaming tunnel temperature continuously monitored.

6.3 Finished Product Tests

- Moisture content: De mai jos 10%.

- Oil content (taitei prajiti): 18–24%.

- Cooking time: 3–5 minutes.

- Perioada de valabilitate: 6–12 luni.

7. Cost Analysis for Instant Noodle Production Line

7.1 Investiție inițială

- Small-scale semi-automatic line: $100,000- 200.000 USD.

- Medium-scale automatic line: $300,000–$600,000.

- Large-scale fully automatic line: $800,000–$1,500,000.

7.2 Costuri de exploatare

- Materii prime: Făină, ulei, flavorings (50–60% of cost).

- Muncă: Operators, ingineri, QC staff.

- Energy: Electricitate + steam fuel (gas or coal).

- Întreţinere: Spare parts and cleaning.

7.3 Profitability Example

- Cost per pack: $0.10–$0.15.

- Pret de vanzare: $0.25–$0.40 (depending on market).

- Gross margin: 50–60%.

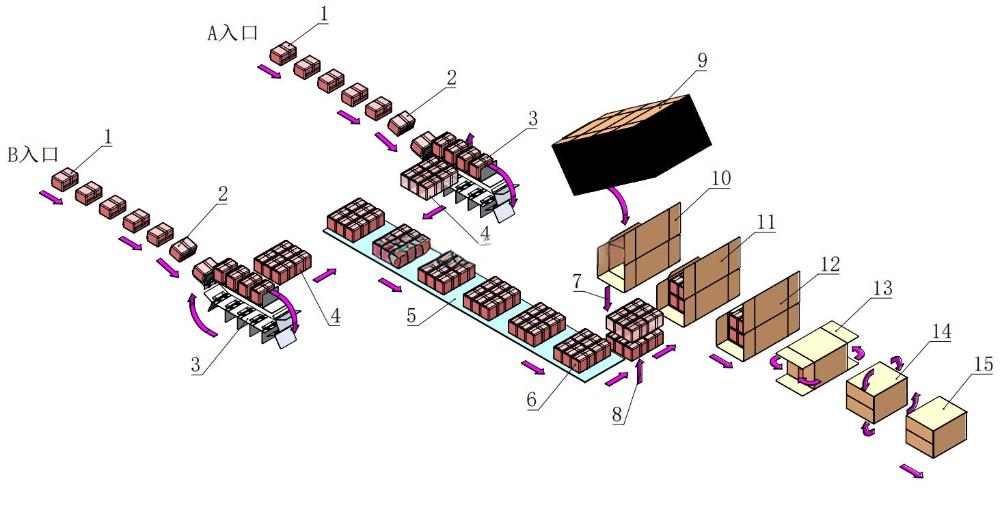

8. Factory Layout Design

Un tipic aspectul fabricii follows this sequence:

- Raw Material Storage Area – flour silos, oil tanks, seasoning storage.

- Amestecarea & Dough Room – flour mixing and dough sheet rolling.

- Aburire & Frying Area – requires steam boiler connection and exhaust system.

- Răcire & Packaging Area – separated from hot processing areas.

- Quality Control Lab – small room for testing samples.

- Finished Product Warehouse – dry, ventilated, pest-free environment.

Flow should be linear, avoiding cross-contamination between raw and finished goods.

9. Regulatory and Safety Considerations

- Food Safety Standards: HACCP, ISO 22000, FDA (for export).

- Worker Safety: Heat protection in frying section, slip-proof flooring.

- Fire Safety: Oil fryers must include fire suppression systems.

- Environmental Compliance: Proper oil filtration and wastewater treatment.

10. Tips for Success in the Instant Noodle Business

- Choose the right product type based on market demand.

- Invest in flavor R&D. – consumers often choose noodles for taste.

- Partner with reliable machinery suppliers offering after-sales service.

- Start with scalable capacity and expand as sales grow.

- Focus on packaging design to stand out on store shelves.

Choose us as your Instant noodle production line manufacturer

Building an instant noodle production line requires significant investment but offers strong profitability in a global growth market. By carefully selecting the right equipment, designing an efficient production flow, and implementing strict quality control, manufacturers can produce noodles that meet both consumer demand and international food safety standards.

With the right strategy, an instant noodle factory can evolve from a regional supplier to an international brand.