As the demand for fresh pasta increases in restaurants, hoteluri, and food manufacturing facilities, commercial spaghetti making machine are becoming essential equipment. These machines streamline the production process, ensuring consistency, viteză, and top-quality spaghetti every time.

În acest ghid, we’ll explore everything from machine types and features to tips for choosing the right model and maintaining it.

What Is a Commercial Spaghetti Making Machine?

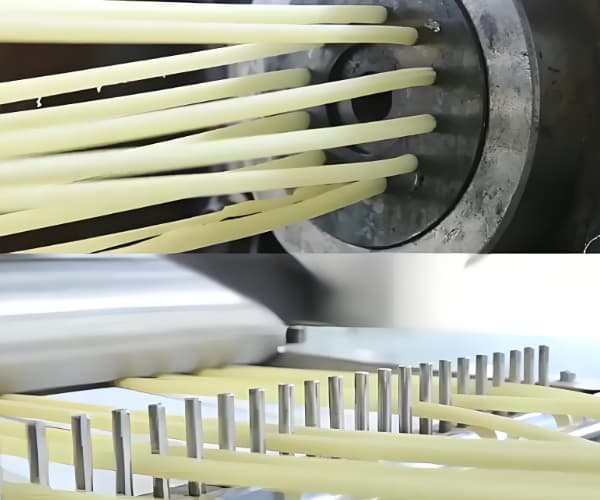

A comercial spaghetti making machine is an industrial-grade kitchen appliance designed to produce large quantities of spaghetti. It automates the mixing, frământare, and extrusion of dough through specialized dies to form perfectly shaped spaghetti strands.

Types of Commercial Spaghetti Machines

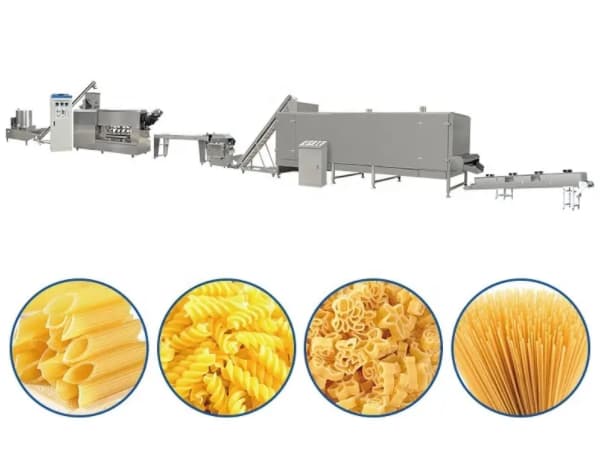

🏭 Automatic Spaghetti Extruder Machine

Un automatic spaghetti extruder machine is designed to handle the complete pasta-making cycle. From mixing flour and water to extruding the dough into spaghetti, this type of machine minimizes manual labor and maximizes efficiency.

Caracteristici:

- Built-in mixer and extruder

- Variable speed controls

- Die attachments for multiple pasta types

- Stainless steel construction for hygiene

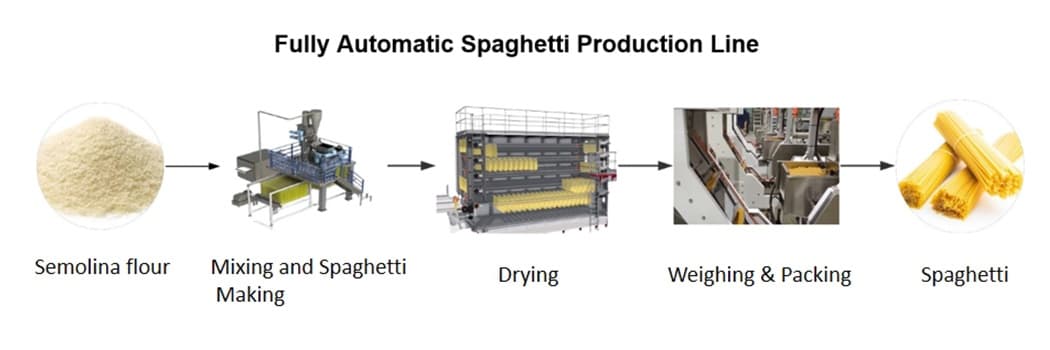

🍝 Industrial Spaghetti Production Line

Un industrial spaghetti production line is ideal for large food factories. These systems include dough mixers, extruders, transportoare, drying tunnels, and cutting stations.

Beneficii:

- Output of 100–1000+ kg per hour

- Fully automated systems

- Conceput pentru 24/7 operație

- Customizable layouts for factory use

🧑🍳 Restaurant-Grade Spaghetti Maker

For smaller operations such as restaurants or fresh pasta shops, compact commercial spaghetti makers offer efficiency and ease of use.

Repere:

- Tabletop or floor-standing models

- Fast die-switching system

- Output from 10 la 50 kg/oră

- Ideal for daily fresh pasta preparation

Benefits of Using a Professional Spaghetti Machine

✅ Consistency in Size and Texture

With a professional spaghetti machine, each strand of pasta has uniform thickness, textură, and length—crucial for even cooking and visual appeal.

✅ Time-Saving and Efficient

Automating the dough preparation and extrusion process saves time and reduces labor costs, making it easier to meet peak demand periods.

✅ Cost-Effective for Bulk Production

In-house pasta production eliminates the need to purchase pre-made products, cutting down costs while improving product freshness and quality.

Long-Tail Benefits of Industrial Spaghetti Making Equipment

💼 Best Commercial Spaghetti Machine for Restaurants

Restaurants that produce fresh pasta daily benefit from small to mid-range commercial models. These machines are easy to use, clean, and can switch pasta types with minimal downtime.

🏢 Heavy-Duty Spaghetti Maker for Factories

Food factories require machines capable of continuous operation and high throughput. These are integrated with drying and packaging systems for a streamlined workflow.

💧 Commercial Pasta Machine with Built-in Water Cooling

Some high-capacity models come with water cooling systems to prevent overheating during long hours of production, especially critical in industrial settings.

Types of Spaghetti You Can Make

🍽️ Classic Spaghetti (2mm Diameter)

Standard spaghetti made from semolina flour and water is perfect for most recipes, from carbonara to marinara.

🧄 Whole Wheat Spaghetti

Made with whole wheat flour, this variant is ideal for health-conscious consumers and is easily processed using commercial machines with adjustable dough mixing capabilities.

🌱 Gluten-Free Spaghetti

Machines that allow flour variation (like rice flour or corn flour) enable businesses to cater to gluten-intolerant customers.

How to Choose the Right Commercial Spaghetti Maker

🧮 1. Determine Your Production Needs

Evaluate your daily or hourly production goals:

- Small restaurant: 10–30 kg/hr

- Pasta shop: 30-100 kg/h

- Factory: 100–1000+ kg/hr

🔌 2. Power Source and Voltage

Ensure the machine is compatible with your facility’s electrical setup. Industrial models usually require 380V or 440V 3-phase power.

🔧 3. Die Compatibility and Variety

Look for models that offer interchangeable dies for other pasta shapes like linguine, tagliatelle, or macaroni. More die options mean more menu flexibility.

🧼 4. Ease of Cleaning and Maintenance

Choose machines with detachable parts and dishwasher-safe components. Stainless steel finishes resist rust and bacterial growth.

Commercial Spaghetti Machine Specifications Table

| Model | Ieșire (kg/h) | Putere (kW) | Dimensiuni (mm) | Material | Die Options |

|---|---|---|---|---|---|

| SPG-30 | 30 | 2.2 | 500x450x700 | SS304 | 5+ |

| SPG-100 | 100 | 4.0 | 800x700x1100 | SS304/316 | 10+ |

| SPG-300 Pro | 300 | 7.5 | 1200x950x1300 | SS316 | 15+ |

| Line-SPG-1000 | 1000 | 18.0 | Customized | SS316 + Teflon | 20+ |

Best Commercial Spaghetti Machine Brands

🇮🇹 1. La Monferrina (Italia)

Famous for reliability and innovation, offering machines from 10 kg/h to full-scale production lines.

🇺🇸 2. EMILIOMITI (STATELE UNITE ALE AMERICII)

Well-known in North America for compact machines for artisan pasta shops and restaurants.

🇨🇳 3. JY Machinery (China)

Offers affordable, CE-certified pasta machines with custom options for SMEs and startups.

🇩🇪 4. Fava (Germania)

Specializes in high-volume, continuous pasta lines including spaghetti, fettuccine, and macaroni.

Sfaturi de curățare și întreținere

🧽 1. Clean Dies and Extrusion Head Daily

Use warm water and a soft brush. Avoid harsh chemicals to preserve brass dies.

🧴 2. Lubricate Moving Parts Monthly

Apply food-safe lubricants to moving parts like drive shafts and gears to reduce wear.

🔄 3. Replace Worn Components Periodically

Inspect extrusion screws, cutting blades, and seals for wear and replace as needed to maintain output quality.

Spaghetti Machine Safety Features to Look For

- Butoane de oprire de urgență

- Protecție la supraîncălzire

- Covered belts and motors

- Low-noise operation

- Non-slip base or lockable wheels

Commercial Spaghetti Machine Price Guide

| Dimensiunea mașinii | Gama de prețuri (USD) |

|---|---|

| Mic (10–30 kg/h) | $1,500 - $3,500 |

| Mediu (50-100 kg/h) | $4,000 - $9,000 |

| Large Industrial (100–500 kg/h) | $10,000 - $35,000 |

| Complete Line (1000+ kg/h) | $50,000 - $150,000+ |

Prices vary based on brand, material, Nivel de automatizare, and included accessories.

Aplicații în industria alimentară

🍽️ Restaurants and Pasta Bars

Proaspăt, made-to-order spaghetti enhances the guest experience and can be a unique selling point.

🏪 Retail Pasta Brands

Local pasta brands can use commercial machines to manufacture and package spaghetti for supermarkets.

🛒 Supermarkets and Deli Counters

In-house pasta production for take-home products or ready-to-cook meal kits.

🎪 Catering pentru evenimente

On-site production of fresh spaghetti for festivals, nunti, and banquets.

Comparison: Manual vs Commercial Spaghetti Machines

| Caracteristică | Manual Spaghetti Maker | Commercial Spaghetti Machine |

|---|---|---|

| Ieșire | 1–2 kg/hour | 10–1000+ kg/oră |

| Forța de muncă necesară | Ridicat | Scăzut |

| Skill Level Needed | Mediu spre ridicat | Scăzut (automatizate) |

| Best Use Case | Home use | Restaurant/Factory |

| Cost | $50 - $300 | $1,500 - $100,000+ |

Întrebări frecvente

❓ Can one machine make different types of pasta?

Da. Most machines support interchangeable dies to produce spaghetti, linguine, Fusilli, si mai mult.

❓ Do I need a separate mixer?

Some machines have built-in mixers; others require external dough mixers for large-scale production.

❓ How long does it take to make spaghetti?

It varies by model. Most commercial machines produce 10–100 kg/hour, depending on size and dough type.

Concluzie: Should You Invest in a Commercial Spaghetti Making Machine?

If your business requires consistent, high-quality pasta production, then the answer is a resounding yes. A commercial spaghetti making machine offers speed, precizie, și eficiența costurilor, while also allowing you to control the ingredients and freshness of your product.

From boutique restaurants to massive pasta factories, choosing the right machine tailored to your needs can elevate your culinary offerings and streamline your production.