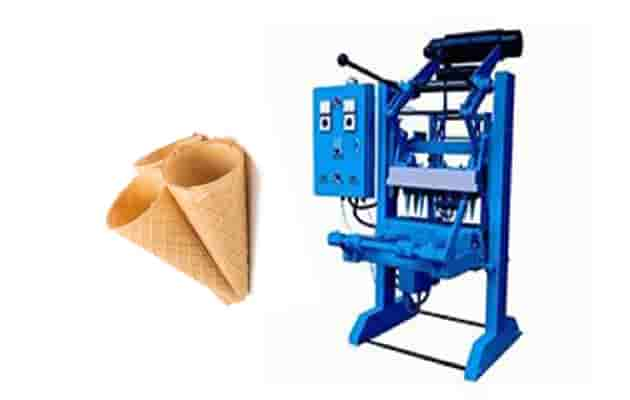

Când clienții intră în magazinul tău de înghețată, nu doar tânjesc dulceață, ci caută o experiență. Mirosul conurilor de vafe proaspăt coapte, crunchul de sub o lingură cremoasă, căldura a ceva făcut la comandă. Acolo este un comercial aparat de conuri de vafe pentru inghetata nu doar satisface o nevoie, ci creează un avantaj competitiv.

Ce face ca o mașină comercială de conuri de vafe să fie diferită de unitățile domestice?

Mulți noi intrați în industria alimentară presupun că se pot descurca cu un aparat de conuri în stil casnic, dar acesta este un pas greșit operațional critic.

Diferențele cheie includ:

| Caracteristică | Fier de călcat pentru vafele domestice | Producător de conuri comercial |

|---|---|---|

| Capacitate de ieșire | 1-2 conuri la 5-7 minute | 60-120 conuri pe oră |

| Ciclul de funcționare | Intermitent | Continuu |

| Materialul plăcii | Aluminiu turnat | Fontă cu acoperire antiaderentă sau oțel inoxidabil alimentar |

| Recuperarea temperaturii | Lent | Miez de încălzire rapidă cu control PID |

Unitatile comerciale sunt proiectat pentru un randament ridicat fără a sacrifica uniformitatea, asigurându-se că fiecare con menține o nuanță aurie consistentă, textură, și flexibilitate pentru rulare.

„Am trecut de la un producător de uz casnic la un Krampouz dublu, și am văzut instantaneu o creștere de trei ori a eficienței producției în timpul orelor de vârf,” spune Nora Liu, fondatorul Republicii Sundae (salon din LA). „Și acel con a sporit vânzările cu 42%.”

Tipuri de echipamente comerciale pentru cornet de înghețată: Alegeți Pe baza fluxului de ieșire

1. Fier de călcat cu conuri de vafe semi-automat (Model standard)

- Cel mai bun pentru magazinele producătoare <300 conuri/zi

- Porționarea manuală a aluatului și rularea conurilor

- Aproximativ. $250– 800 USD investitie

2. Mașini cu două plăci sau cu două etaje

- Două fiare de călcat independente cu termostate separate

- Ieșire: ~100–180 conuri/oră

- Ideal pentru magazinele cu statii multi-scooping

- Preţ: $800– 1.500 USD

3. Producători de conuri automate rotative

- Alimentare automată cu aluat, presare, și rostogolire

- Pentru la nivel de întreprindere sau producție la nivel de fabrică

- Ieșire: 1,000–3.000 conuri/oră

- Preţ: $5,000– 25.000 USD+

Pro Insight:

Dacă vânzările dvs. la orele de vârf depășesc 15 conuri în 10 minute, rularea manuală a conurilor devine un blocaj. În acest caz, fie treceți la funcționarea cu două etaje, fie prerulați în timpul ferestrelor de pregătire în afara orelor de vârf.

Profiluri termice și selecția materialelor: De ce contează

Tipuri de miezuri de încălzire

- Încălzitoare pe bază de bobine oferă o coacere stabilă la nivel mediu, dar poate avea puncte fierbinți.

- Miezuri pe bază de inducție oferi recuperare termică mai rapidă (ideal pentru conuri spate în spate).

Compoziția farfurii

- Fontă: Preîncălzire mai lungă, dar reținere superioară a căldurii - excelent pentru marginile crocante.

- Aluminiu acoperit cu teflon: Încălzire rapidă, dar o durată de viață mai scurtă și predispusă la deformare în cazul utilizării intense.

A 2023 sondaj de la Asociația Frozen Dessert a aratat ca:

Magazinele care foloseau aparate de fabricare a vafelor pe bază de fontă aveau o 9% coeficient de satisfacție mai mare al clarității conului în recenziile clienților decât cei care folosesc unități din aluminiu.

Flux de lucru din lumea reală: Integrarea unei stații de conuri de vafe

Să examinăm cum Linge & Roll Cremery în Austin și-au optimizat linia:

Înainte de optimizare

- Un aparat de conuri de vafe cu o singură placă

- 5-timp de pregătire minute pentru fiecare con

- Răcire frecventă a plăcilor între utilizări

→ Rezultat: 7-minut de așteptare medie per client

După optimizare

- Upgrade la a ALDKitchen cu două capete mașină cu control digital PID

- Implementat flux de lucru pentru 2 persoane: unul pentru oala de aluat, unul pentru rulare

- A construit un suport de răcire conic folosind tăvi din plasă de calitate alimentară

→ Rezultat: 2.5-minut de schimbare a clientului, +28% în valoarea medie a comenzii prin intermediul vânzărilor de conuri

Loturi, Pre-rulare, și Perioada de valabilitate: Tactici operaționale care funcționează

Nu întotdeauna trebuie să coaceți la cerere. Multe magazine de succes precoaceți și depozitați conurile în timpul orelor de pregătire.

Sfaturi pentru depozitare:

- Răciți complet conurile pe rafturi înainte de depozitare

- Utilizați etanș, recipiente cu alimente căptușite cu siliciu pentru a păstra crocanta

- Perioada de valabilitate: 24-36 de ore pentru o textura optima

„Facem trei loturi de 60 de conuri la 8 A.M, care acoperă traficul de prânz. În timpul eliberării liceului la 3 P.M, trecem la laminare la cald pentru efectul de aromă,” spune Javier Corroza, coproprietar al Helado Fresco din Miami.

Acest abordare hibridă asigură eficiența fără a sacrifica atracția senzorială a clienților.

Dezvoltarea rețetei: Știința unui con crocant

Iată un reteta de baza de aluat de conuri de vafe comerciale, plus ajustări pentru performanță.

Raport de bază (Pe 100 conuri):

- Făină: 1,200g

- Zahăr: 800g

- ouă: 12 mare

- Unt: 500g (topit)

- Vanilie: 25g

- Sare: 10g

- Lapte sau apă: 600-750 ml (ajustați pentru vâscozitate)

Ajustări de performanță:

- Adăuga 2% pudră de malț pentru o aromă mai profundă și rumenire

- Utilizare amidon de cartofi (5–7%) pentru o textura snap imbunatatita

- Înlocuiește puțin unt cu ulei de cocos rafinat pentru o reținere mai mare a clarității

Pentru vârf: Măsurați vâscozitatea aluatului utilizând un Consistometru Bostwick pentru a menține uniformitatea ieșirii între loturi.

Evitați aceste capcane comune în producția de conuri de vafe

| Problemă | Cauza probabilă | Soluţie |

|---|---|---|

| Conuri prea moi după răcire | Umiditate ridicată în aluat | Reduceți lapte/apă cu 10%, crește timpul de coacere |

| Conurile care se sparg în timpul rulării | Nu este suficient de fierbinte | Rulează înăuntru 5 secunde după ridicare |

| Conuri lipite de farfurii | Condiment incomplet sau teflon vechi | Aplicați agent de degajare de calitate alimentară sau înlocuiți farfuria |

Întotdeauna rulați testarea QC în timpul primului dvs. lot zilnic. Un cornet insuficient gătit sau un fier lipicios poate crea un stoc de producție la care nu vă puteți permite 5 P.M.

Perspective de marketing: Transformă fabricarea conurilor de vafe într-o experiență vizuală

Consumatorii mănâncă cu ochii — și cu nasul.

Coacerea conului viu ca instrument de marketing:

- Poziționați aparatul de conuri lângă fereastra de comandă

- Utilizați ventilatoare de evacuare pentru a emana mirosul către intrare

- Evidențiați „Proaspăt copt zilnic” în meniuri

- Oferi conuri în ediție limitată (matcha, vârtej de ciocolată, scorţişoară)

Sfat demn de Instagram:

Oferi conuri scufundate (de exemplu., ciocolata cu migdale zdrobite) si incarca $1.00 suplimentar. Această actualizare simplă vă poate crește veniturile zilnice cu $50–100 cu un minim de cap.

Valori cheie pentru monitorizarea rentabilității investiției pe stația dvs. conică

| Metric | Benchmark |

|---|---|

| Costul conului pe unitate | $0.07– 0,11 USD |

| Încărcarea conului peste ceașcă | $0.50– 1,00 USD |

| Vânzări medii de conuri/zi | 80–150 (sezonul de vârf) |

| Perioada de rambursare este activată $1,000 maşină | 15-30 de zile |

Odată ce ați depășit pragul de rentabilitate a investiției, conurile devin a produs cu marjă mare— de multe ori cu un markup de 700–1.200%..

Producători de conuri comerciale de top (2024 Recomandări)

| Marca | Model | Tip | Ieșire/h | Preţ (USD) |

|---|---|---|---|---|

| ALDBucătărie | Fier dublu | Manual | 120 | $699 |

| Krampouz | Seria profesională | Manual | 140 | $980 |

| VEVOR | Semi-Automat | Manual | 100 | $299 |

| TT Italia | Seria RCM | Automat | 2,000+ | $9,800 |

Dacă vă gândiți la scară, contactați producătorii despre Dimensiuni de conuri personalizate OEM sau plăci în relief la comandă pentru diferențierea mărcii.

Concluzie: Deține Conul, Creșteți marca

Pe piața competitivă a deserturilor din 2025, o aparat comercial de conuri de vafe pentru înghețată este mai mult decât un simplu aparat – este o declarație. Le spune clienților că vă pasă de calitate, prospeţime, si experienta. Oferă mărcii dvs. un punct de diferență, niciun concurent nu este înghețat, conul din cutie se poate potrivi.

Indiferent dacă lucrați 80 conuri pe zi sau crescând în mii, mașina potrivită combinată cu fluxul de lucru inteligent și controlul rețetei poate crește-ți profiturile și povestea mărcii tale.