Pe piața de gustări cu creștere rapidă de astăzi, Beef sacadat a apărut ca unul dintre cele mai populare și profitabile produse. Bogat în proteine, de lungă durată, și ideal pentru diverși consumatori, Producția Jerky este o industrie în plină expansiune. in orice caz, Producerea sacadării la scară de înaltă calitate necesită echipamente avansate. Acolo este un Mașină Jerky de vită comercială intră.

Vom explora Proces complet de fabricație sacadat folosind echipamente industriale de vită sacad, furnizați a Fișă tehnică de date, și împărtășiți de ce suntem de încredere Producător și exportator de mașini de vită comercială cu o amprentă globală.

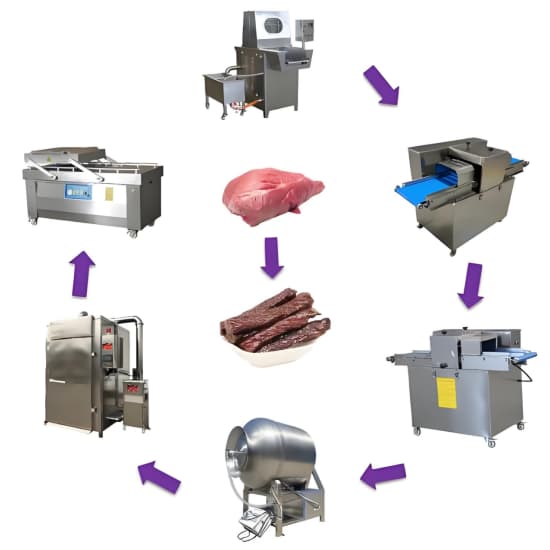

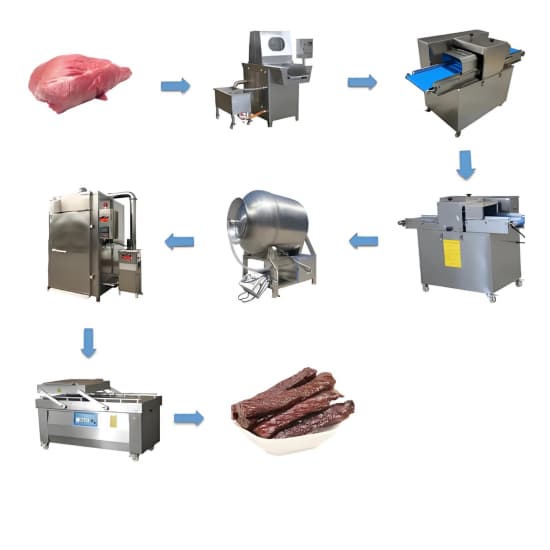

1. Flux de lucru industrial de prelucrare a cărnii de vită industrială

A comercial Mașină de prelucrare cu vită sacadă simplifică și automatizează procesul de realizare. Reduce costurile forței de muncă, îmbunătățește consistența, și asigură îndeplinirea standardelor de siguranță alimentară. Mai jos este o defalcare pas cu pas a modului în care se face carnea de vită folosind Echipamente profesionale de fabricație sacadat.

1.1 Selectarea cărnii și pregătirea inițială

Procesul începe cu Selectarea tăieturilor de vită slabă Ca rotund de top, rotund de jos, sau SIRLOIN. Materia primă de înaltă calitate asigură un produs final mai bun.

- Mașini de tuns manuale sau automate Îndepărtați excesul de grăsime.

- Felii uniforme se fac folosind un Mașină de feliere a cărnii- reglabil tipic de la 2mm la 10 mm grosime.

1.2 Marinarea folosind tumblere comerciale jalnice

Marinarea este esențială pentru aromă și textură. A Comercial Tumbler Jerky Tumbler sau Mașină de Marinare în vid asigură pătrunderea profundă a condimentului.

- Tehnologie de vid Reduce timpul de marinație la 15-30 de minute.

- Mașinile se pot descurca până la 300 kg pe lot în funcție de model.

Aromarea opțională poate fi ajustată folosind cronometre programabile și setări de rotație.

1.3 Drenarea și încărcarea

După marinație:

- Feliile de carne sunt drenate pe rafturi de picurare sau tăvi.

- Aceste tăvi sunt apoi încărcate pe cărucioare compatibile cu cuptor de uscare cu aer cald sau Camera de deshidratare.

1.4 Uscare cu cuptor de uscare a circulației aerului cald

Acesta este Etapa de bază în procesul de producție sacadat.

Noastre deshidrator de circulație a aerului cald sau Cuptor de uscare sacadat:

- Utilizări Controlul temperaturii PID și flux de aer cu mai multe straturi

- Menține chiar temperatura (gamă: 40–90 ° C.)

- Timp de uscare reglabil de la 4 la 12 ore În funcție de conținutul de umiditate și de grosimea cărnii

- Capacitate: din 50 kg la 1,000 kg pe lot

Camera de deshidratare păstrează aroma și textura în timp ce prelungește durata de valabilitate.

1.5 Răcire și ambalaje finale

După uscare:

- Jerky este mutat în Transportoare de răcire sau tăvi din oțel inoxidabil.

- Este apoi sortat și opțional tăiat în benzi sau bucăți.

- Mașinile de ambalare în vid sigilează sacadarea pentru piețe cu amănuntul sau cu ridicata.

Ambalajul se face adesea folosind Ambalaje automate de vid cu opțiuni de spălare a azotului pentru conservarea extinsă.

2. Specificații și modele de mașini de vită comercială

Mai jos este un eșantion Fișă tehnică de date dintre cele mai vândute noastre Mașini comerciale de carne de vită comercială. Aceste mașini sunt modulare și scalabile - ideale pentru mici, mediu, și linii de producție sacadate la scară industrială.

2.1 Tabelul de specificații tehnice: Mașini comerciale de procesare sacadative

| Numele mașinii | Model | Capacitate (kg/lot) | Putere (kW) | Voltaj | Dimensiuni (mm) | Material |

|---|---|---|---|---|---|---|

| Felie de carne pentru sacad | DS-MJ300 | 100–300 kg/oră | 1.5 kW | 220V/50Hz | 1000 × 600 × 900 | Sus304 Oțel inoxidabil |

| Mașină de marinație cu vid | DS-VT500 | 500 kg/lot | 2.2 kW | 380V/50Hz | 1600 × 1100 × 1300 | Sus304 Oțel inoxidabil |

| Cuptor de uscare a circulației aerului cald | DS-HC1000 | 1,000 kg/lot | 24–36 kW | 380V/50Hz | 3000 × 2200 × 2300 | Sus304 + Izolare |

| Transportor de răcire | DS-CC200 | 200 kg/h | 0.75 kW | 220V/50Hz | 2500 × 800 × 850 | Sus304 |

| Mașină de ambalare în vid | DS-VP400 | 200 pachete/ore | 2.5 kW | 220V/50Hz | 1000 × 800 × 1050 | Sus304 |

💡 Tensiune personalizată și capacitate disponibile la cerere.

2.2 Eficiența energetică și caracteristicile de siguranță

Toți ai noștri Echipament industrial de vită industrială este proiectat cu caracteristici de economisire a energiei și standarde de siguranță ridicate:

- Straturi de izolare termică Reduceți pierderea de energie în timpul uscării

- Protecție la supraîncălzire și senzori auto-scutire

- Certificări CE și ISO

- Deplin calitate alimentară 304 Construcție din oțel inoxidabil

Acestea asigură durata de viață lungă, Conformitatea igienei, și funcționare eficientă.

3. Producătorul dvs. de încredere și exportatorul de echipamente industriale sacadate

Suntem un Producător profesionist și exportator global de mașini de vită comercială de vită. Cu peste un deceniu de experiență în fabricarea mașinilor alimentare, Am furnizat echipament pentru fabricile de produse alimentare, Procesoare de carne, și mărci Jerky din toată lumea America de Nord, Europa, Asia, Africa, și Orientul Mijlociu.

3.1 De ce să alegem mașina noastră de vită comercială Jerky?

- ✅ Soluții de linie end-to-end: De la feliere la ambalaje

- ✅ Oem & Personalizare: Mașini adaptate la aspectul plantei dvs.

- ✅ Control strict al calității: Inspectăm fiecare unitate înainte de expediere

- ✅ Asistență tehnică: Asistență la distanță și instalare la fața locului

- ✅ Prețuri competitive: Vânzări directe din fabrică - Fără intermediari

- ✅ Transport rapid: Depozit strategic și parteneriate logistice

3.2 Aplicații ale mașinilor noastre profesionale sacadate

Mașinile noastre sunt utilizate pe scară largă în:

- Fabrici comerciale de vită comercială

- Instalații de fabricație a contractelor alimentare

- Plante de prelucrare a cărnii

- R&D Bucătărie pentru dezvoltarea produsului Scaun

- Companii de gustări care doresc integrare verticală

De asemenea, susținem Turcia sacadă, Pui sacadat, Pork sacadat, și Pește sacadat producție.

4. Întreținerea și garanția echipamentelor de carne uscată comercială

Menținerea ta Mașină Jerky de vită comercială asigură performanța optimă și consistența produsului. Oferim instruire completă și ghiduri pentru a vă ajuta să vă mențineți utilajele cu ușurință.

4.1 Întreținerea de rutină include:

- Curățarea și igienizarea suprafețelor după fiecare ciclu de producție

- Lubrifiant piese mobile lunar

- Verificarea circuitelor electrice și a controalelor de temperatură

- Înlocuirea filtrelor în deshidratoare în mod regulat

4.2 Garanție & Suport după vânzare

Toate mașinile vin cu un 12–18 luni garanție, În funcție de model. Sprijinul nostru după vânzare include:

- Piese de schimb gratuite în perioada de garanție

- Consultare tehnică pe viață

- Manuale video și PDF

- Diagnostice la distanță programate prin apel video

5. Întrebări frecvente despre mașini de vită comercială

Q1: Care este capacitatea cuptoarelor tale de uscare sacadate?

A: Cuptoarele noastre variază de la 50 kg la 2,000 kg pe lot. De asemenea, oferim uscătoare de tip tunel pentru producție continuă.

Q2: Mașinile pot gestiona alte carne precum puiul sau curcanul?

A: Da! Echipamentul nostru este potrivit pentru diverse carne, inclusiv păsări de curte și pește.

Q3: Oferiți instalarea peste mări?

A: Da, Oferim suport de instalare la distanță și putem expedia ingineri la cerere.

Q4: Ce certificări au mașinile dvs.?

A: CE, ISO9001, și design de calitate alimentară care respectă FDA.

Q5: Pot obține o linie de producție personalizată, sacadată?

A: Absolut. Realizăm dimensiunile mașinii, capacitate, Voltaj, și aspectul nevoilor dvs. specifice.

Concluzie: Crește -ți afacerea cu mașinile noastre industriale de vită sacad

Cererea de sacadat crește rapid - și investește în drept Mașină Jerky de vită comercială Poate fi un schimbător de jocuri. De la o feliere și condiment eficient la uscare cu volum mare și ambalaje sigure, Mașinile noastre sunt concepute pentru Scalați -vă operațiunea profitabil și igienic.

Ca a producător și exportator principal, Livrăm soluții de producție de înaltă performanță, susținute de asistență cu servicii complete. Permiteți -ne să vă ajutăm să transformați carnea crudă într -un produs global de gustări.