Nell’industria dei dessert di oggi, i coni di cialda croccanti sono diventati l'anima di ogni gelato. Dalle più grandi fabbriche di gelato del mondo alle gelaterie boutique, un pezzo di attrezzatura guida silenziosamente questo successo: IL produttore di coni di wafer. Questa macchina, preciso ma creativo, consente ai produttori di trasformare ingredienti semplici: la farina, zucchero, and oil—into perfectly baked cones that define the customer’s first bite.

While customers enjoy the taste, business owners understand that the key to consistent flavor and quality lies in the machine itself. Scegliere il diritto macchina per la produzione del cono wafer is not only a technical decision but a strategic investment in efficiency, qualità, and brand reputation.

The Technology Behind a Wafer Cone Maker

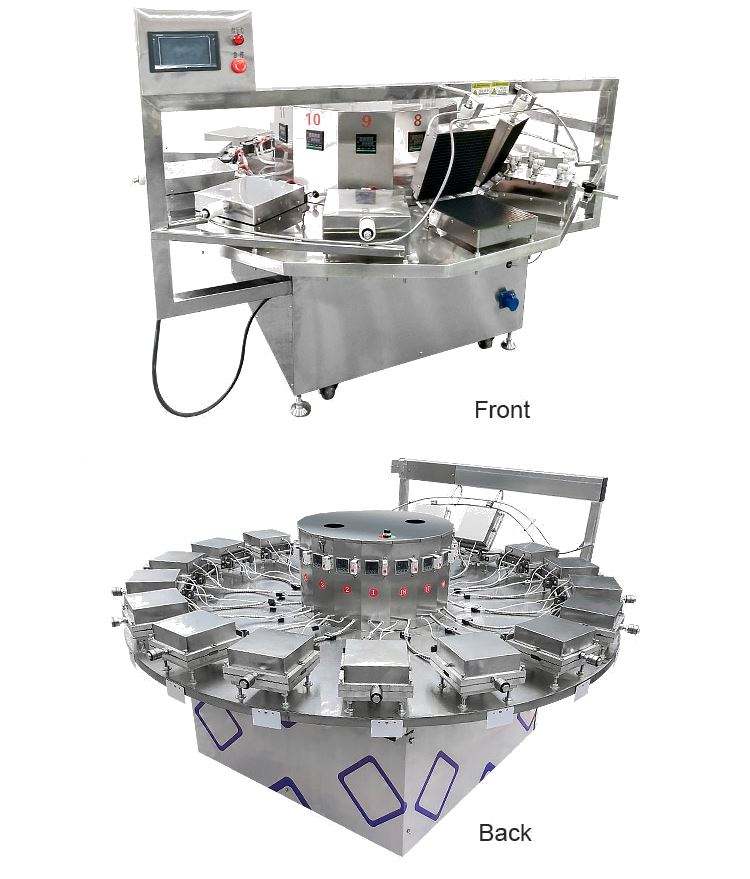

Unlike a regular waffle iron or home-use cone press, a professional industrial wafer cone maker integrates mechanical, thermal, and digital control systems to handle large-scale production. Inside the machine, precise temperature control and automated rolling ensure each cone has the same golden color, freschezza, e trama.

The production process begins with a specially formulated batter—mixed in a tank until smooth. The batter is then evenly deposited onto hot baking plates, forming thin sheets. In pochi secondi, those sheets are rolled into cone shapes by the cone rolling unit, cooled naturally on conveyors, and finally discharged for packaging.

The entire process is fast, automatico, and remarkably consistent. For manufacturers producing thousands of cones daily, this automation is crucial to meet market demand while maintaining uniform quality.

Automatic Wafer Cone Machine: Innovation for Efficiency

IL macchina automatica per coni di cialda represents the evolution of traditional cone baking. Older manual models required workers to pour batter and roll each cone individually—a labor-intensive process. Modern automatic systems, Tuttavia, can produce up to 10,000 cones per hour with minimal supervision.

Each baking mold opens and closes rhythmically, forming dozens of cones simultaneously. IL PLC touchscreen control panel allows operators to set baking temperature, rotation speed, and cone size with precision. Gas or electric heating systems can be selected based on production needs.

This innovation not only increases speed but also ensures better consistency, which is vital for ice cream brands that rely on product uniformity.

Ice Cream Cone Making Machine vs. Macchina del cono waffle

Many customers wonder about the difference between a produttore di coni di wafer e a macchina per coni per waffle. Though both produce ice cream cones, they serve different purposes and markets.

UN cono di cialda is thin, croccante, and light. It breaks with a satisfying crunch and is ideal for large-scale, cost-effective production. It’s the cone you’ll find in supermarkets, vending machines, and fast-food ice cream brands.

UN cono waffle, al contrario, is thicker, più dolce, and often made fresh in shops. Its pattern and caramelized flavor suit premium desserts. Macchine come la macchina per cuocere il cono della cialda O produttore di coni di zucchero operate at slightly lower temperatures and handle denser batter.

In other words:

- Wafer cone = industrial mass production, low cost per piece.

- Waffle cone = artisanal presentation, higher price point.

Understanding this distinction helps investors choose the right machinery for their target market.

The Role of the Wafer Cone Production Line

For large-scale factories, a single machine is often not enough. Ecco dove a wafer cone production line arriva.

This fully automated system combines several interconnected machines:

- Batter Mixer and Storage Tank – Prepares and feeds batter automatically.

- Wafer Baking Oven – Contains dozens of molds for continuous baking.

- Cone Rolling Machine – Rolls each baked sheet into cones.

- Trasportatore di raffreddamento – Stabilizes texture before packaging.

- Stacker and Counter – Organizes cones into batches for wrapping.

The result is a streamlined process capable of producing 24/7, delivering thousands of perfect cones per hour with minimal human input.

Produttori come Macchina alimentare DT design modular lines, allowing clients to start small and expand capacity as business grows.

Commercial Wafer Cone Maker Features That Matter

Al momento dell'acquisto di un commercial wafer cone maker, several key specifications determine performance and ROI.

1. Construction and Durability

Food-grade stainless steel structure ensures hygiene and corrosion resistance. Cast iron or aluminum alloy molds maintain heat evenly.

2. Energy Source Options

Both electric and gas heating are available. Gas models heat faster and suit high-output environments, while electric systems are cleaner and easier to install indoors.

3. Temperature and Time Control

Digital thermostats and PLC systems guarantee precise baking—preventing over-browning or undercooked cones.

4. Customizable Cone Shapes and Sizes

From small bite-sized cones (50 mm) to jumbo waffle-style cones (115 mm), molds can be customized for shape, diametro, and pattern.

5. Safety Systems

Pulsanti di arresto di emergenza, overload protection, and automatic cooling fans make the production environment safe for operators.

Industrial Wafer Cone Machine Technical Overview

A typical industrial macchina per cuocere i coni di wafer includes 24–60 pairs of molds arranged in a rotary oven. Each pair operates automatically: batter is poured, baked, and rolled in a continuous loop.

| Parametro | Specifica |

|---|---|

| Modello | DT-WF800 |

| Voltaggio | 380V / 50Hz |

| Energia | 12 - 18 kW |

| Capacità di output | 5,000–10,000 cones/hour |

| Fonte di riscaldamento | Gas or Electric |

| Dimensione del cono | 60–115 mm |

| Sistema di controllo | Touchscreen del PLC |

| Peso | 1,500 - 2,000 kg |

| Materiale | Acciaio inossidabile + Cast Iron Mold |

| Garanzia | 12 mesi |

This setup allows for long production hours, low maintenance, e qualità costante, making it the backbone of many ice cream factories worldwide.

Energy Efficiency and Cost Considerations

Energy cost plays a big role in the long-term profitability of cone production. Un moderno produttore di coni di wafer with smart heat recovery and insulation can reduce energy use by up to 20%. Gas models often provide lower operational costs, especially in regions with high electricity prices.

The price of a professional Macchina del cono wafer varies widely:

- Entry-level manual models: around USD $500–$1,000

- Semi-automatic units: USD $3,000–$5,000

- Fully automatic wafer cone lines: USD $10,000–$50,000+

While the initial investment may seem high, the reduced labor cost and increased output often allow businesses to recover their investment within one or two production seasons.

Maintenance Tips for a Long-Lasting Wafer Cone Machine

Keeping your machine clean and well-maintained ensures reliability and safety. Dopo ogni ciclo di produzione, wipe baking molds with a non-abrasive cloth and remove batter residues. Once a week, inspect mechanical parts and apply food-grade lubricant to moving components.

Avoid using sharp tools that could scratch the plates. Calibration should be checked monthly to ensure even heating. Many modern machines from Macchina alimentare DT come with self-diagnosis systems that display alerts if temperature or rotation speed deviates from the preset range.

The Global Market for Wafer Cone Makers

As global ice cream consumption increases—particularly in Asia, il Medio Oriente, and Latin America—the market for automatic wafer cone machines continues to expand. Local producers are investing in machinery to meet rising domestic demand rather than importing cones from abroad.

Technological improvements, ad esempio AI-driven temperature control E energy-efficient burners, make production more sustainable. Nel frattempo, customization options—like branding on cones or different edge designs—help manufacturers differentiate their products.

Why Choose DT Food Machine for Your Wafer Cone Equipment

When selecting a partner for your cone production line, experience and support matter. Macchina alimentare DT stands out as one of the most trusted manufacturers of wafer cone makers E macchine per coni di cialda in China, exporting to more than 60 Paesi.

The company offers:

- Custom-designed cone molds for different shapes and capacities.

- Turnkey wafer cone production lines.

- CE and ISO-certified machines with energy-saving systems.

- Comprehensive after-sales service, including installation training and spare parts supply.

DT Food Machine’s philosophy is simple: build machines that produce quality and consistency every time.

Future Trends in Wafer Cone Production

Automation and digitalization are defining the next era of food processing. Future wafer cone baking machines will use smart sensors to control moisture levels, adjust baking temperature in real-time, and even predict maintenance needs before breakdowns occur.

Sustainability is another focus—eco-friendly gas burners, recyclable packaging, and reduced energy consumption are becoming key factors for international buyers.

As global dessert chains expand, demand for reliable and efficient macchine per la produzione di coni gelato will continue to rise, making early investment in advanced equipment a strategic move.

Build a Profitable Ice Cream Business with the Right Machine

UN produttore di coni di wafer is more than just a piece of equipment—it’s the foundation of every successful ice cream brand. From the aroma of freshly baked cones to the crisp bite that delights customers, everything starts with the precision and performance of your machine.

By choosing the right model, maintaining it properly, and working with a trusted supplier like Macchina alimentare DT, you can achieve high output, qualità costante, and strong profitability in your cone production business.