Le patatine sono tra gli spuntini più popolari in tutto il mondo. Dai supermercati e ristoranti ai venditori ambulanti, La domanda di patatine croccanti non smette mai di crescere. Per le aziende che intendono entrare in questo mercato, Scegliere il diritto macchina per patatine è il primo e più importante passo. Uno dei fattori chiave nel prendere questa decisione di investimento è il prezzo macchina per patatine. In questo articolo, esploreremo la fascia di prezzo delle macchine per patatine con capacità comprese tra 100kg e 1000 kg all'ora, analizzare cosa influenza il costo, e spiegare come selezionare l'attrezzatura giusta per le vostre esigenze di produzione.

1. Introduzione alle macchine per patatine

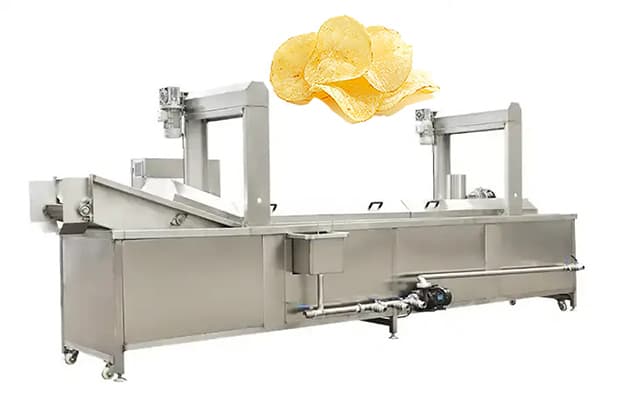

UN macchina per patatine è un sistema di lavorazione alimentare progettato per il lavaggio, buccia, fetta, friggere, stagione, e confezionare le patate in patatine croccanti. A seconda della scala di produzione, le macchine possono essere piccole unità semiautomatiche o grandi linee di produzione completamente automatiche.

Per le piccole imprese, UN 100macchina per patatine da kg/h potrebbe essere sufficiente. Ma per fabbriche medie o grandi, capacità di 300kg/h, 500kg/h, o anche 1000kg/h sono più adatti. Ogni livello di capacità produttiva comporta costi diversi, specifiche, e requisiti.

2. Perché il prezzo delle macchine per patatine è importante

Quando si avvia o si aggiorna un'attività di patatine, il prezzo della macchina non è solo un numero. Rappresenta:

- Investimento di capitale: Il denaro iniziale necessario per iniziare la produzione.

- Capacità di produzione: Il prezzo più elevato spesso riflette una maggiore capacità e un'automazione avanzata.

- Efficienza a lungo termine: Le macchine ben progettate consumano meno energia e riducono gli sprechi.

- Qualità del prodotto: Macchine migliori garantiscono un gusto coerente, struttura, e aspetto.

Così, comprendere il prezzo della macchina per patatine è essenziale per bilanciare il budget, efficienza, e la qualità del prodotto.

3. Gamma di capacità della macchina per patatine fritte: 100kg-1000kg

Ecco una panoramica delle capacità tipiche delle macchine e del loro significato per la tua attività:

| Capacità della macchina | Adatto per | Utenti tipici | Fascia di prezzo (Dollaro statunitense) |

|---|---|---|---|

| 100kg/h | Piccoli negozi, ristoranti locali, startup | Produttori locali di snack, nuovi imprenditori | $5,000 - $15,000 |

| 200-300kg/h | Produzione media | Distributori regionali, imprese in crescita | $15,000 - $35,000 |

| 500kg/h | Fabbriche medio-grandi | Marche di snack, produttori a contratto | $35,000 - $60,000 |

| 1000kg/h | Grandi impianti industriali | Marchi internazionali, fornitori ad alto volume | $60,000 - $120,000 |

Nota: I prezzi variano a seconda del design della macchina (semiautomatico vs completamente automatico), materiale (qualità dell'acciaio inossidabile), efficienza energetica, e personalizzazione.

4. Fattori chiave che influenzano il prezzo della macchina per patatine fritte

4.1. Livello di automazione

- Macchine semiautomatiche: Costo inferiore ma richiede manodopera.

- Macchine completamente automatiche: Investimenti più elevati ma riduzione dei costi di manodopera e garanzia di una produzione continua.

4.2. Materiale della macchina

- Alta qualità acciaio inossidabile 304/316 garantisce la sicurezza alimentare e una maggiore durata.

- I materiali più economici riducono i costi ma possono causare problemi di igiene o corrosione.

4.3. Capacità produttiva

- Una macchina da 100 kg/h è compatta ed economica.

- Un sistema da 1000 kg/h richiede attrezzature più grandi, controlli più avanzati, e un maggiore approvvigionamento energetico, aumentando così il prezzo.

4.4. Tecnologia & Caratteristiche

- Sistemi di frittura automatica con filtrazione dell'olio.

- Macchine per il lavaggio e la pelatura continua.

- Controllo digitale della temperatura.

- Linee integrate di stagionatura e confezionamento.

Più avanzate sono le funzionalità, più alto è il prezzo.

4.5. Fonte di energia

- Le macchine possono essere alimentate da elettricità, gas, o diesel.

- I sistemi alimentati a gas sono spesso più economici in termini di costi di esercizio, ma il prezzo iniziale potrebbe essere più alto.

5. Ripartizione dei costi di una linea di produzione di patatine fritte

Quando si calcola il prezzo della macchina per patatine, è utile comprendere la distribuzione dei costi all’interno di una linea di produzione:

- Lavaggio & Unità di pelatura - 10-15% del costo totale.

- Affettatrice - 5-10%.

- Macchina per sbollentare - 10-15%.

- De-watering & Unità di asciugatura - 5-10%.

- Macchina frittura - 25-35% (parte più costosa).

- De-oiling & Sistema di raffreddamento - 5-10%.

- Macchina per condimenti - 5-10%.

- Macchina da imballaggio - 15-20%.

6. Confronto prezzi macchina per patatine fritte: 100kg contro 1000 kg

100kg/ora Sistema

- Prezzo: $5,000 - $15,000

- Ideale per piccole imprese o progetti pilota.

- Richiede più lavoro manuale.

500kg/ora Sistema

- Prezzo: $35,000 - $60,000

- Soluzione equilibrata per le aziende di medie dimensioni.

- Buona efficienza con investimenti moderati.

1000kg/ora Sistema

- Prezzo: $60,000 - $120,000

- Progettato per la grande scala, 24/7 operazioni.

- Completamente automatizzato, con filtrazione dell'olio e controlli avanzati.

7. Costi aggiuntivi da considerare

Oltre al prezzo della macchina, le aziende dovrebbero pianificare:

- Installazione & Formazione: $2,000 - $10,000 a seconda della complessità.

- Spedizione & Dogana: Varia in base al paese.

- Pezzi di ricambio & Manutenzione: Budget annuale di 5-10% del costo della macchina.

- Consumo di energia: Bollette di luce o gas.

- Configurazione di fabbrica: Approvvigionamento idrico, stoccaggio del petrolio, ventilazione, e progettazione dello spazio di lavoro.

8. ROI (Ritorno sugli investimenti) di macchine per patatine fritte

Un’attività di patatine può essere altamente redditizia. Consideriamo un esempio:

- Costo della patata cruda: $0.30/kg

- Prezzo di vendita delle patatine: $3.00/kg

- Prodotto: 1kg di patate = 0,35 kg di patatine

- Margine di profitto: In giro $0.70 - $1.20 per kg di patate utilizzate

Con a 500kg/h macchina, una fabbrica può processare 4.000 kg al giorno (8 ore). Questo è uguale 1,400kg di patatine al giorno, con profitti potenziali superiori $1,000 al giorno. Ciò significa che l'investimento nella macchina può essere recuperato all'interno 6-12 mesi.

9. Come scegliere la macchina per patatine giusta

Nel valutare prezzo macchina per patatine, non guardare solo i numeri. Considerare:

- La tua scala di produzione: Inizia in piccolo o diventa grande a seconda delle dimensioni del mercato.

- Esigenze di automazione: Riduci il costo della manodopera con l'automazione completa se il budget lo consente.

- Standard di qualità: Scegli l'acciaio inossidabile per uso alimentare per l'igiene e la conformità all'esportazione.

- Reputazione dei fornitori: Collabora con produttori affidabili che forniscono l'installazione, formazione, e servizio post-vendita.

- Personalizzazione: Alcuni fornitori offrono soluzioni personalizzate per i sapori di condimento, progettazione dell'imballaggio, e fonti energetiche.

10. Tendenze future nelle macchine per patatine fritte

- Efficienza energetica: Macchine con minor consumo di olio ed elettricità.

- Monitoraggio digitale: Macchine abilitate all'IoT per monitorare la produzione in tempo reale.

- Patatine più sane: Tecnologia di frittura e patatine al forno a basso contenuto di olio.

- Design compatti: Modelli salvaspazio per fabbriche alimentari urbane.

Queste innovazioni potrebbero aumentare leggermente il prezzo delle macchine per patatine, ma porteranno risparmi a lungo termine e una maggiore domanda da parte dei consumatori.

11. Perché scegliere DT Food Machine

Se hai intenzione di investire in a macchina per patatine (100capacità kg-1000 kg), il prezzo è un fattore importante, ma l’affidabilità, durata, e il servizio conta altrettanto.

A Macchina alimentare DT, siamo specializzati nella progettazione e fornitura di alta qualità macchine per patatine per aziende di ogni dimensione. Le nostre macchine sono realizzate in acciaio inossidabile per uso alimentare, dotato di automazione avanzata, e progettato per prestazioni a lungo termine.

Se hai bisogno di un 100kg/h macchina per una startup o a 1000kg/h linea completamente automatica per la produzione su larga scala, Macchina alimentare DT fornisce la soluzione giusta a prezzi competitivi, supporto per l'installazione, e un eccellente servizio post-vendita.

👉 DT Food Machine: il tuo fornitore professionale di macchine per patatine fritte