1. Introduzione alla produzione di burro di arachidi

Il burro di arachidi è una crema spalmabile amata in tutto il mondo, Realizzato per arrostire e macinare le arachidi in una pasta liscia o croccante. Non è solo un punto fermo in molte diete occidentali, Ma sta anche guadagnando trazione nei mercati globali a causa del suo valore nutrizionale e versatilità. Un moderno linea di produzione del burro di arachidi offre efficiente, scalabile, e soluzioni igieniche per la lavorazione commerciale.

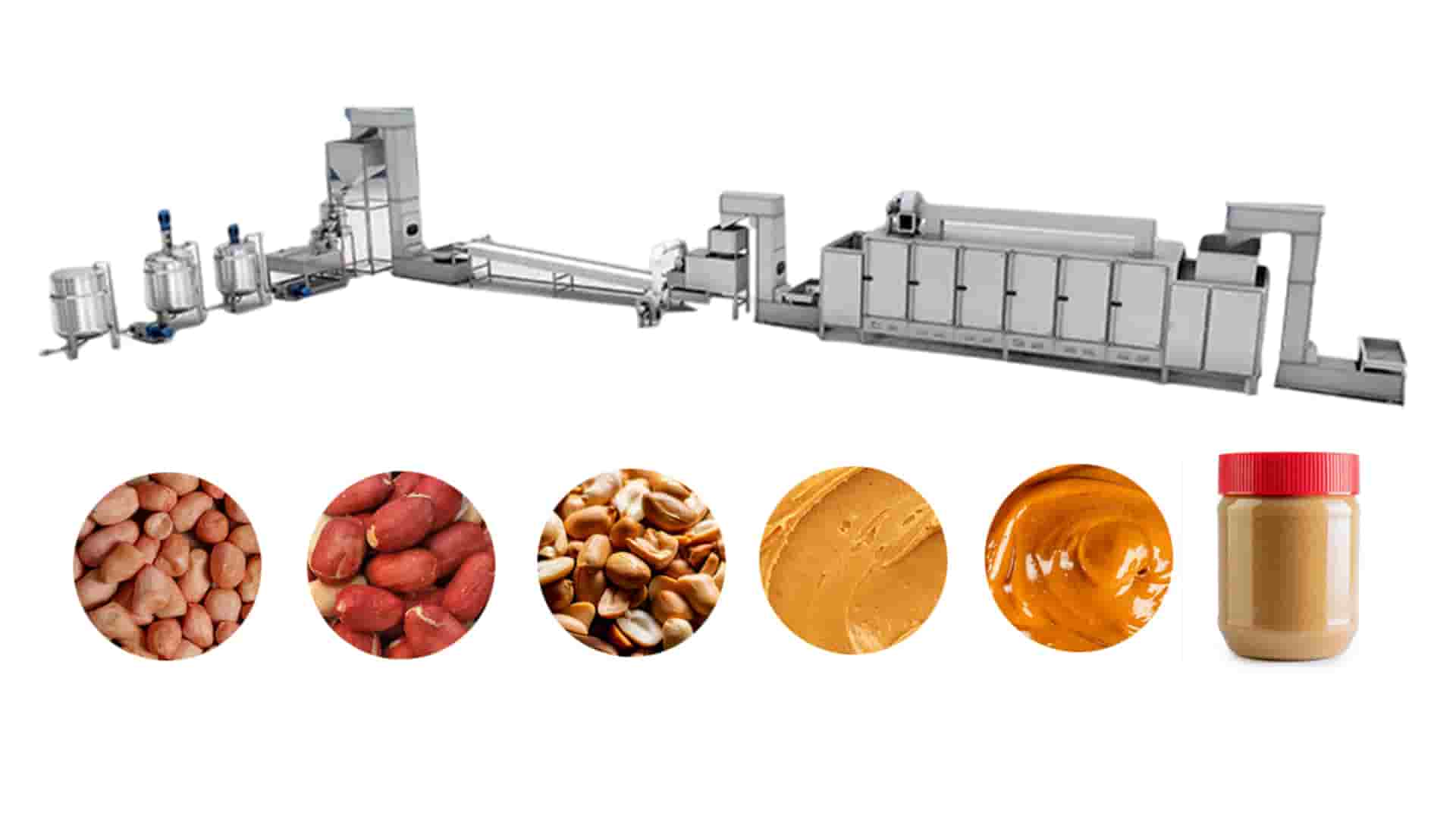

2. Cos'è una linea di produzione di burro di arachidi?

UN linea di produzione del burro di arachidi è un sistema integrato di macchinari e processi progettati per convertire le arachidi crude in burro di arachidi confezionato. Comprende varie unità per la torrefazione, peeling, macinazione, miscelazione, riempimento, e imballaggio. Spesso indicato come a sistema di produzione della pasta di noci O linea di lavorazione industriale delle arachidi, garantisce una produzione in serie con elevati standard di qualità e sicurezza.

3. Panoramica del mercato e tendenze della domanda globale

L’industria del burro di arachidi è in forte espansione, soprattutto con l’aumento dei consumatori attenti alla salute. Le tendenze del mercato includono:

- Richiesta di burro di arachidi biologico e senza zucchero

- Crescente popolarità in Asia, Africa, e Sudamerica

- Utilizzo crescente negli snack proteici, frullati, e ricette vegane

- Automazione e linee di produzione economicamente vantaggiose guidano l'espansione globale

4. Componenti chiave di una linea di produzione di burro di arachidi

- Tostatrice di arachidi

- Trasportatore di raffreddamento

- Macchina pelatrice

- Macchina per macinare e omogeneizzare

- Serbatoio di miscelazione e miscelazione

- Serbatoi di stoccaggio

- Unità di degasaggio

- Pastorizzatore o sterilizzatore

- Riempimento, sigillatura, e macchine etichettatrici

- Sistemi di confezionamento di fine linea

5. Macchina per tostare le arachidi: Fondamento dello sviluppo del sapore

La tostatura è essenziale per il sapore, aroma, e lo sviluppo del colore. I sistemi di tostatura comuni includono:

- Torrefazioni in lotti (per operazioni di piccole e medie dimensioni)

- Tostatrici a nastro continuo (per la produzione in grandi volumi)

- Intervallo di temperatura: 160–180 ° C.

- Sistemi di tostatura dell'olio opzionali

6. Sistema di trasporto di raffreddamento: Controllo della temperatura per una consistenza ottimale

Dopo la tostatura, le arachidi devono essere raffreddate rapidamente per evitare una tostatura eccessiva. Caratteristica dei trasportatori di raffreddamento:

- Cinghie in rete di acciaio inossidabile

- Sistemi ad aria forzata

- Sensori di temperatura automatizzati

7. Macchina per sbucciare le arachidi: Rimozione della pelle rossa per la purezza

Il peeling migliora il colore e la durata di conservazione. Le macchine possono elaborare:

- 200–1000 kg/h

- Rimozione della pelle secca o bagnata

- Separazione pneumatica della pelle

- Selezionatore di kernel opzionale

8. Macinatrice per arachidi: Macinazione fine e omogeneizzazione

Questo è il cuore della linea di pasta di arachidi. Le caratteristiche includono:

- Macina colloidale o macina a pietra

- Finezza di macinazione regolabile (50–100 micron)

- Emulsione ad alta velocità (fino a 2800 giri/min)

- Parti di contatto in acciaio inossidabile

9. Unità di miscelazione e miscelazione: Personalizzazione del gusto e della consistenza

La miscelazione consente l'integrazione degli ingredienti:

- Zucchero, sale, Miele, olio di palma

- Cacao, proteine in polvere, vaniglia

- Possono essere miscelatori discontinui o continui

- Dotato di camicia riscaldante e agitatore

10. Serbatoi di stoccaggio e di contenimento: Stoccaggio temporaneo igienico

Utilizzato per contenere il burro di arachidi prima del riempimento:

- Serbatoi incamiciati per il controllo della temperatura

- Agitatori per evitare la sedimentazione

- Design compatibile con CIP

11. Macchina per degasaggio sotto vuoto: Migliorare la stabilità del prodotto

I sistemi di aspirazione rimuovono le bolle d'aria:

- Prevenire l'ossidazione

- Migliora la viscosità

- Prolungare la durata di conservazione

12. Pastorizzazione e sterilizzazione: Garantire la sicurezza alimentare

A seconda delle esigenze del mercato:

- Pastorizzatore per lavorazione a 65–85°C

- Sterilizzatore UHT per prodotti a lunga conservazione

- Monitoraggio in linea della temperatura e della pressione

13. Macchine Riempitrici e Confezionatrici: Dal barattolo al mercato

Il burro di arachidi finale viene riempito in contenitori:

- Vaso, spremere la bottiglia, bustina, o secchio

- Ugelli di riempimento servoazionati

- Sistemi antigoccia e CIP

- Produttività: 10–100 contenitori/min

14. Etichettatura, Coding, e attrezzature per la sigillatura

Include:

- Sigillatrici ad induzione di calore

- Maniche termoretraibili

- Codifica a getto d'inchiostro o laser per la tracciabilità

15. Soluzioni di fine linea: Palettizzatori e Sistemi di Avvolgimento

Automatizzare i processi di fine linea:

- Pallettizzazione robotizzata

- Avvolgimento termoretraibile

- Macchine per sigillare cartoni

16. Automazione nella produzione di burro di arachidi

- Sistemi di automazione basati su PLC

- Sensori IoT per il monitoraggio in tempo reale

- Controllo SCADA e report batch

17. Considerazioni sul design industriale: Disposizione, Flusso di lavoro, e Spazio

- Design lineare o ad U

- Ingresso della materia prima all'uscita del prodotto finito

- Spazio per la manutenzione e gli spazi di sicurezza

18. Personalizzazione della linea di produzione della pasta di arachidi

- Capacità: da 100 kg/ora a 2,000 kg/h

- Croccante vs. opzioni fluide

- Aggiunta di cioccolato, mandorla, sesamo

- Integrazione con linee tostatura nocciole e snack

19. Componenti aggiuntivi comuni: Miscelatori, Iniettori di sapore, Sistemi di schiaccianoci

- Miscelatori a nastro

- Dosatori di aromi a vite

- Dispenser a doppia consistenza

- Serbatoi sottovuoto con doppia camicia

20. Pulizia sul posto (CIP) Sistema: Mantenere l'igiene nella produzione

- Completamente automatico o semiautomatico

- Coinvolge l'acqua calda, lavaggio alcalino, risciacquo acido

- Riduce i tempi di inattività e i costi di manodopera

21. Specifiche tecniche delle macchine chiave

| Attrezzatura | Capacità | Energia | Materiale |

|---|---|---|---|

| Torrefazione | 100–1000 kg/h | 25–60kW | SS304/SS316 |

| Smerigliatrice (mulino colloidale) | 100–2000 kg/h | 5–15kW | SS304, per uso alimentare |

| Riempitivo | 10–100 bpm | 3–8kW | Controllato da PLC |

| Serbatoio del miscelatore | 200–2000 litri | 2–10kW | Con agitatore |

22. Efficienza energetica e considerazioni ambientali

- Utilizzo di sistemi di recupero del calore

- Condotte e serbatoi isolati

- Materiali di imballaggio riciclabili

23. Analisi dei costi: CapEx e OpEx nella produzione di burro di arachidi

- Piccola linea: $15,000 - $50,000

- Linea media: $50,000 - $150,000

- Linea completamente automatica: $200,000 - $1,000,000+

- ROI in genere entro 12-24 mesi

24. Conformità normativa e certificazioni di livello alimentare

- FDA, Ce, Iso 22000, HACCP

- Buone pratiche di produzione (GMP)

- Sistemi di controllo e tracciabilità degli allergeni

25. Misure e standard di controllo della qualità

- Campionamento e test (microbiologia, viscosità, gusto)

- Monitoraggio in linea del pH e della temperatura

- Rilevazione di metalli e ispezione a raggi X

26. Risoluzione dei problemi e manutenzione delle apparecchiature per il burro di arachidi

- Difetti comuni: intasamento, surriscaldamento del motore, macinazione irregolare

- Programmi di manutenzione preventiva

- Disponibilità kit ricambi

27. Vantaggi di investire in una linea di produzione di burro di arachidi chiavi in mano

- Installazione più rapida

- Supporto tecnico del venditore

- Flusso di processo ottimizzato

- Minore rischio di mancata corrispondenza delle apparecchiature

28. Aumentare la produzione: Dalla piccola impresa alla fabbrica

- A partire dalle tostatrici batch e dalle riempitrici manuali

- Passaggio alla macinazione e al confezionamento automatici

- Ingresso nel mercato attraverso canali di nicchia o di esportazione

29. Casi studio: Impianti di lavorazione del burro di arachidi di successo

- Caso A: Startup di burro di arachidi biologico negli Stati Uniti

- Caso B: Esportatore di medie dimensioni in Nigeria

- Caso C: Grande stabilimento industriale in India

30. Il futuro delle tecnologie di lavorazione del burro di noci

- Fabbriche intelligenti con controllo dell’intelligenza artificiale

- Sistemi di lavorazione multinoci

- Linee di confezionamento completamente robotizzate

- Integrazione con sistemi ERP

31. Come avviare un'attività di produzione di burro di arachidi

- Condurre ricerche di mercato

- Scegli la giusta scala di produzione

- Acquistare terreni e servizi

- Acquista la linea di equipaggiamento

- Assumere e formare il personale

- Rispettare le norme sulla sicurezza alimentare

32. Selezione dei fornitori: Valutazione dei produttori di apparecchiature

- Esperienza e recensioni dei clienti

- Certificazioni globali

- Disponibilità del supporto locale

- Funzionalità ingegneristiche personalizzate

33. Conclusione: Costruire un impianto redditizio per il burro di arachidi

Una qualità elevata linea di produzione del burro di arachidi è la spina dorsale di un'azienda di successo nella produzione di noccioline. Dalla tostatura all'etichettatura, ogni fase influisce sulla qualità e sulla redditività del prodotto. Investire in affidabilità, per uso alimentare, e i sistemi automatizzati garantiscono successo e scalabilità a lungo termine.