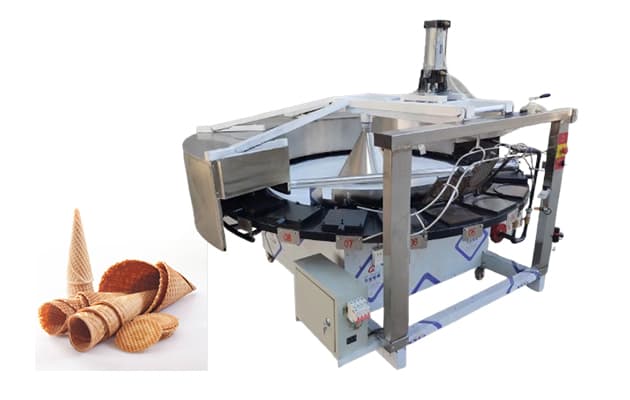

Impostazione di un Macchina per cono gelato-se si tratta di a macchina per coni per waffle, macchina per coni di zucchero, macchina per cuocere i coni di wafer, o completamente linea di produzione di cono di gelato automatico—è uno dei passaggi più importanti prima di iniziare la produzione dei coni. Una macchina installata correttamente garantisce una temperatura di cottura stabile, colore uniforme del cono, Alta efficienza, e lunga durata.

Molti acquirenti acquistano l'attrezzatura ma non conoscono la procedura di installazione corretta. Ciò porta spesso a una cottura non uniforme, errori della macchina, o qualità del cono incoerente. Questa guida ti guiderà attraverso ogni fase dell'installazione, dalla preparazione dell'officina alla calibrazione e alla produzione dei test.

1. Perché una corretta installazione è fondamentale

Una qualità elevata Macchina per cono gelato può operare 24 ore ininterrottamente, ma solo quando è installato correttamente.

Una corretta configurazione garantisce:

- Distribuzione stabile del calore

- Consistenza e croccantezza ottimali del cono

- Minori consumi di gas o elettricità

- Flusso di produzione più fluido

- Costi di manutenzione ridotti

- Meno tempi di inattività

- Qualità del prodotto costante

Un'installazione errata può causare:

- Coni bruciati o poco cotti

- Colore del cono non uniforme

- Perdita della pastella

- Consumo eccessivo di carburante

- Coni rotti o incrinati

- Interruzioni della produzione

Perciò, comprendere il processo di configurazione corretto è essenziale per qualsiasi produttore che avvia un attività di produzione di coni.

2. Preparazione dell'officina prima dell'installazione

Prima di posizionare il produttore di coni industriali, preparare l'officina in base ai requisiti della macchina.

2.1 Requisiti di spazio

Uno standard forno rotante per coni gelato O macchina per cuocere i coni di wafer esigenze:

- Spazio libero attorno alla macchina: 1–1,5 metri per manutenzione

- Un appartamento, terreno pianeggiante

- Spazio di flusso di lavoro fluido per gli operatori

- Spazio per l'impastatrice, trasportatore, e stazione di imballaggio

Per una produzione completamente automatica:

- Spazio aggiuntivo per il trasportatore di raffreddamento

- Sistema di conteggio dei coni

- Sezione imballaggio

2.2 Requisiti ambientali

La produzione del cono gelato richiede un ambiente controllato:

- Temperatura: 10–35°C

- Umidità: <75%

- Senza polvere e asciutto

- Buona circolazione dell'aria

- Nessuna luce solare diretta sulla sezione di cottura

L'elevata umidità può ammorbidire i coni o causare problemi di conservazione.

2.3 Preparazione dell'approvvigionamento energetico

A seconda del tipo di macchina:

Macchine per coni gelato con riscaldamento a gas

- Linea GPL o metano

- Regolatore di pressione del gas

- Valvola gas antideflagrante

- Tubi in acciaio o in gomma certificata

- Ventilazione adeguata

Macchine per cono gelato con riscaldamento elettrico

- 380V trifase

- Voltaggio stabile (±5%)

- Messa a terra adeguata

- Stabilizzatore di tensione (consigliato per l'Africa, America Latina, Asia meridionale)

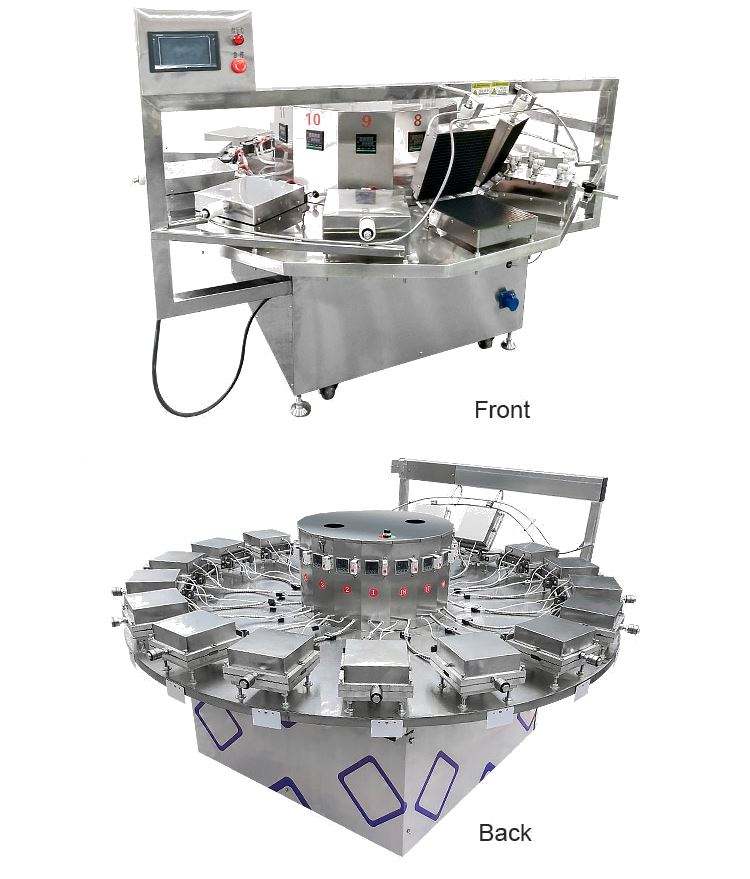

3. Controllo della macchina per il cono gelato prima dell'installazione

Quando ricevi l'attrezzatura, ispezionare i seguenti componenti:

- Stampi da forno / piatti

- Bruciatori a gas o tubi riscaldanti

- Armadio elettrico

- Catena di trasmissione

- Stampi per la laminazione dei coni

- Pompa per pastella

- Pannello di controllo HMI/PLC

- Trasportatore di raffreddamento

- Pezzi di ricambio (molle, cinture, sensori, fusibili)

Controllare eventuali danni dovuti al trasporto o dispositivi di fissaggio allentati.

4. Passo-passo: Come impostare una macchina per coni gelato

Di seguito è riportato il processo di configurazione completo per entrambi macchine per coni semiautomatiche E linee automatiche di produzione di coni industriali.

Fare un passo 1: Posizionare la macchina correttamente

Posiziona il macchina per fare i coni per waffle O forno di cottura a cono di wafer rotante su una superficie piana.

Requisiti:

- Mantenere 1 metro di spazio intorno

- Utilizzare un righello di livello per garantire la stabilità

- Evitare pavimenti umidi o irregolari

- Lasciare spazio per l'alimentazione della pastella e il sistema di raffreddamento

Il corretto posizionamento previene le vibrazioni e garantisce una cottura uniforme.

Fare un passo 2: Collegare l'impianto del gas (Se applicabile)

Alimentato a gas Macchine del cono di zucchero richiedono una pressione stabile.

2.1 Connessione alla pipeline

Utilizzo:

- Gasdotto indipendente

- Regolatore di alta pressione

- Tubi d'acciaio

- Nastro sigillante in teflon

2.2 Requisiti di pressione del gas

- GPL: 30–50mbar

- Gas naturale: 15–25 mbar

2.3 Ispezione di sicurezza

- Applicare acqua saponata sui giunti per verificare le perdite

- Assicurarsi che la ventola di scarico funzioni

- Installare l'arresto di emergenza del gas

Non avviare mai i bruciatori finché non è stata completata la prova di tenuta.

Fare un passo 3: Collegare l'impianto elettrico

Anche per macchine da riscaldamento a gas, i controlli richiedono energia elettrica.

Controllare quanto segue:

- Filo di terra

- Interruttore di alimentazione principale

- Cablaggio del quadro elettrico

- Connessioni relè

- Funzione di arresto di emergenza

- Il PLC/HMI si avvia correttamente

Requisiti elettrici

- Trifase 380V

- Tensione stabilizzata

- Messa a terra sicura (<4OH)

Fare un passo 4: Installa la miscelazione della pastella & Sistema di alimentazione

Tuo macchine per la lavorazione del cono gelato necessita di un sistema di alimentazione della pastella coerente.

4.1 Macchina per impastare la pastella

Preparare la pastella con:

- Farina

- Zucchero

- Acqua

- Olio

- Aromatizzazione

Mescolare per 10–20 minuti per coerenza.

4.2 Collegare la pompa della pastella

- Utilizzare tubi flessibili per alimenti

- Verificare la presenza di perdite

- Garantire un'aspirazione e un'uscita regolari

4.3 Regola la quantità di riempimento (Dosaggio)

Il dosaggio determina lo spessore del cono:

- Coni piccoli: 8–15 g

- Coni medi: 12-25 g

- Coni grandi: 20–40 g

Regolazione tramite PLC o valvola meccanica a seconda del modello.

Fare un passo 5: Prova a secco (Nessuna pastella)

Prima di aggiungere la pastella, esegui il produttore di coni industriali vuoto.

Controllo:

- Movimento della catena di trasmissione

- Rotazione della piastra

- Stato della fiamma del gas

- Risposta del riscaldamento elettrico

- Rumore del motore

- Aumento della temperatura

Di solito è necessario il preriscaldamento 8–12 minuti.

Fare un passo 6: Aggiungi la pastella e avvia la produzione di prova

Una volta preriscaldato, iniziare il primo lotto di prova.

- Avviare il sistema di dosaggio

- Lascia che la pastella entri negli stampi

- Osservare la qualità della cottura

- Controllare l'uniformità del colore del cono

- Se necessario, regolare lo spessore

6.1 Controllo della temperatura

Impostazioni tipiche:

| Tipo di cono | Temperatura |

|---|---|

| Coni di cialda | 160–180 ° C. |

| Coni di zucchero | 180–200°C |

| Coni di waffle | 190–220°C |

6.2 Tempo di cottura

Dipende dal modello:

- 45–90 secondi per ciclo

Fare un passo 7: Regolare il sistema di rotolamento del cono

Il cono deve avere la forma perfetta.

Controllo:

- Chiusura a punta

- Spessore della parete

- Precisione della forma

- Nessuna crepa

Regolare:

- Pressione di rotolamento

- Allineamento dello stampo

- Temperatura del mandrino del cono

Fare un passo 8: Raffreddamento e stabilizzazione dell'umidità

I coni freschi sono ancora morbidi.

Il raffreddamento avviene tramite:

- Tunnel di raffreddamento ad aria

- Nastro trasportatore

- Vassoio di raffreddamento

Tempo di raffreddamento: 2–6 minuti.

Un corretto raffreddamento previene la deformazione.

Fare un passo 9: Test di qualità finale

Ispezionare:

- Colore del cono

- Croccantezza

- Forma e angolo

- Lunghezza

- Levigatezza

- Nessuna bolla o foro

Solo dopo che si sarà verificata una qualità stabile, la produzione potrà iniziare ufficialmente.

5. Problemi comuni e soluzioni durante l'installazione

Problema 1: Colore del cono non uniforme

- Fiamma del gas non uniforme → pulire i bruciatori

- Temperatura errata → regolare il riscaldamento

- Dosaggio non uniforme → calibrare la pompa

Problema 2: Perdita della pastella

- Piastre non chiuse saldamente → regolare la cerniera

- Troppa pastella → ridurre il dosaggio

Problema 3: I coni si rompono facilmente

- Pressione troppo alta → regolare lo stampo di formatura

- Troppa poca umidità → modificare la ricetta

Problema 4: Coni che si attaccano ai piatti

- Stampi sporchi → pulire & olio

- Piastre surriscaldate → stabilizzano la temperatura

6. Requisiti di sicurezza

Sicurezza nel riscaldamento a gas

- Controllare quotidianamente le perdite

- Installare la valvola di intercettazione del gas

- Mantenere la ventilazione

- Tenere l'estintore nelle vicinanze

Sicurezza elettrica

- Assenza di acqua vicino al quadro elettrico

- Evitare il sovraccarico

- Stringere regolarmente i collegamenti

Sicurezza dell'operatore

- Utilizzare guanti resistenti al calore

- Non bypassare i sensori di sicurezza

- Tenere gli indumenti lontani dalle parti in movimento

7. Requisiti di formazione per gli operatori

Ogni operatore dovrebbe imparare:

- Rapporti di miscelazione della pastella

- Controllo della temperatura e del tempo

- Alimentazione corretta dell'impasto

- Regolazione dello stampo

- Risoluzione dei problemi

- Procedure di pulizia quotidiana

Una buona formazione riduce notevolmente gli sprechi e migliora l’efficienza.

8. Lista di controllo del funzionamento quotidiano

Prima di avviare la macchina:

- Preriscaldare per 10 minuti

- Controlla il gas o l'elettricità

- Confermare il volume di dosaggio

- Stampi puliti

- Garantire la lubrificazione della catena

- Testare la qualità del cono ogni ora

9. Guida alla manutenzione

Quotidiano

- Piatti puliti

- Rimuovere i residui

- Pulisci gli stampini a cono

Settimanale

- Lubrificare i cuscinetti

- Controllare la tensione della catena

- Ispezionare i bruciatori

Mensile

- Ispezione completa della macchina

- Prova di sicurezza

- Controllare PLC e sensori

Con una manutenzione adeguata, tuo Macchina per cono gelato durerà 8–12 anni o più.

Installa la macchina per il cono gelato

Impostazione di un Macchina per cono gelato, se è un macchina per coni per waffle, macchina per la produzione di coni di zucchero, attrezzatura industriale per la cottura del cono di wafer, O linea automatica per la produzione di coni, è la chiave per garantire una produzione stabile e coni di alta qualità.

Preparando correttamente il workshop, collegare gas ed elettricità in tutta sicurezza, calibratura del dosaggio, regolazione degli stampi, testare i risultati della cottura, e formazione degli operatori, la tua fabbrica otterrà:

- Colore del cono uniforme

- Alta efficienza

- Funzionamento stabile 24 ore su 24

- Costi operativi inferiori

- ROI più veloce