Introduzione: Revolutionizing Biscuit Manufacturing

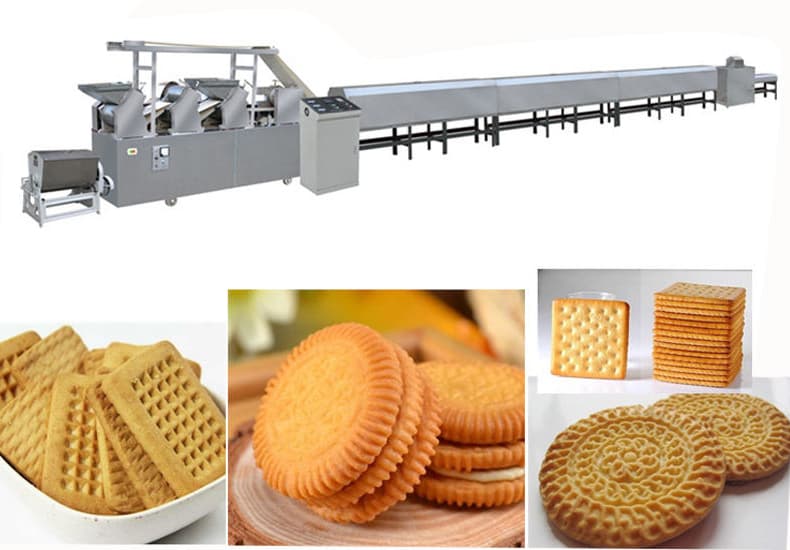

The global demand for high-quality biscuits is continuously on the rise, guidato dalla preferenza dei consumatori per il conveniente, delizioso, e snack convenienti. Per soddisfare questa crescente domanda garantendo al tempo stesso la coerenza, igiene, ed efficienza, UN fully automatic biscuit production line has become the gold standard in industrial food manufacturing.

This article presents a comprehensive overview of the modern linea di produzione di biscotti, detailing the machinery involved, production flow, Specifiche tecniche, automation features, and business advantages for biscuit factories around the world.

1. What Is a Fully Automatic Biscuit Production Line?

UN fully automatic biscuit production line is an integrated system of machinery designed to process raw ingredients into finished, packaged biscuits through automated operations. It eliminates the need for manual labor across various stages such as mixing, formando, cottura al forno, raffreddamento, e imballaggio.

From classic butter cookies to cream-filled sandwich biscuits, this production line accommodates a wide range of product types with high precision and minimal waste.

2. Key Components of a Biscuit Production Line

Un professionista linea di produzione di biscotti consists of the following major equipment:

2.1 Impastatrice

- Mixes flour, grasso, acqua, zucchero, and additives into a uniform dough.

- Opzioni: Horizontal mixer, vertical spiral mixer.

2.2 Dough Feeding Conveyor

- Transfers the dough to the forming machine.

- Speed-controlled with stainless steel construction.

2.3 Biscuit Forming Machine

- Tipi: Rotary moulder, rotary cutter, wire-cut, or extruder.

- Custom molds for different biscuit shapes and patterns.

2.4 Forno da forno a tunnel

- Fonte di calore: Elettrico, gas, diesel, or infrared.

- Uniform baking with temperature zones for precise control.

2.5 Oil Sprayer (Opzionale)

- Applies oil or glaze for shine and flavor enhancement.

2.6 Biscuit Cooling Conveyor

- Reduces the temperature of baked biscuits before packaging.

- Ensures product firmness and prevents condensation.

2.7 Packaging Line

- Tipi: Horizontal flow wrapper, vertical form-fill-seal (Vff).

- Caratteristiche: Date coding, nitrogen flushing, label application.

3. Specifiche tecniche

| Parametro | Specifica |

|---|---|

| Capacità produttiva | 100 kg/ora a 2000 kg/h |

| Biscuit Types Supported | Hard biscuits, soft biscuits, sandwich, biscotti |

| Oven Length | 20m–60m (personalizzabile) |

| Heat Source | Elettrico / Gas / Diesel / GPL |

| Requisiti di alimentazione | 50 KW - 200 kW (varies by configuration) |

| Operating Voltage | 380V/50 Hz 3 Fase (personalizzabile) |

| Sistema di controllo | Plc + HMI (touch screen panel) |

| Materiale | Acciaio inossidabile SUS304 di grado alimentare |

| Moulding Speed | Up to 25–40 molds/min (depending on type) |

| Velocità di confezionamento | 20–120 packs/min |

4. Production Process Flow

Fare un passo 1: Preparazione dell'impasto

Ingredients are weighed and blended in the automatic mixer.

Fare un passo 2: Dough Conveying

The mixed dough is transferred to the forming system without human contact.

Fare un passo 3: Biscuit Forming

Biscuits are shaped using a rotary cutter or extruder, forming dough sheets or individual cookies.

Fare un passo 4: Cottura al forno

The shaped biscuits pass through a tunnel oven with multiple temperature zones.

Fare un passo 5: Raffreddamento

The baked biscuits cool down uniformly via conveyor fans to maintain their shape and texture.

Fare un passo 6: Confezione

Biscuits are aligned, counted, and packed into bags, trays, or cartons automatically.

5. Types of Biscuits Produced

UN linea di produzione di biscotti can manufacture various biscuit styles including:

| Biscuit Type | Descrizione |

|---|---|

| Hard Biscuits | Low sugar/fat, consistenza croccante (PER ESEMPIO., Marie, Soda) |

| Soft Biscuits | High sugar/fat, soft texture (PER ESEMPIO., Shortbread) |

| Cream Sandwich Biscuits | Two biscuits with cream filling |

| Biscotti | Spesso, consistenza gommosa (often wire-cut formed) |

| Wafer Biscuits | Thin layers with cream filling |

6. Automazione & Intelligent Features

- PLC Control Panel – Real-time monitoring and adjustment of parameters.

- Touch Screen HMI – User-friendly interface for recipe setting.

- Temperature Sensors – Multi-zone oven temperature regulation.

- Servo Motor Drive – For precision biscuit forming and alignment.

- Remote Maintenance (Opzionale) – Support via IoT cloud connection.

7. Advantages of a Fully Automatic Biscuit Production Line

✅ 1. Maggiore efficienza

Continuo, high-speed production with minimal downtime.

✅ 2. Qualità costante del prodotto

Accurate ingredient dosing, formando, and baking ensures every biscuit is uniform.

✅ 3. Riduzione del costo del lavoro

Fully automated operation drastically cuts manual labor needs.

✅ 4. Igiene e Sicurezza

Closed processing with food-grade stainless steel equipment meets HACCP and GMP standards.

✅ 5. Energy Optimization

Modern ovens and conveyors are designed for energy efficiency.

8. Factory Layout Consideration

A biscuit factory must be designed based on:

- Capacità produttiva

- Space for raw material and finished goods storage

- Ventilation and heat insulation zones

- Separate zones for dough, cottura al forno, raffreddamento, e imballaggio

- Power and water supply availability

A typical layout may range from 25 meters to over 100 meters in length depending on output and biscuit types.

9. Caso di studio: 1000 kg/h Biscuit Production Line

Client: Snack Manufacturer in Southeast Asia

Setup Highlights:

- 60-meter gas oven

- Dual rotary cutters for shape variation

- Nitrogen-filled horizontal packaging machine

- 24/7 operazione, three shifts

Outcome:

- Production increased 4×

- Waste reduced by 35%

- ROI achieved in 14 mesi

10. Common Buyer Questions (Sezione RFQ)

Q1: What is the minimum capacity available?

UN: Our smallest biscuit production line starts at 100 kg/h, ideal for small and medium-sized factories.

Q2: Can the production line handle different biscuit shapes?

UN: SÌ, molds can be quickly replaced to support various shapes and patterns.

Q3: Is operator training provided?

UN: SÌ, we provide on-site or remote training for your staff.

Q4: Can the line integrate with an existing plant?

UN: Assolutamente. We customize layouts to match existing infrastructure.

Q5: How long is delivery time?

UN: Standard delivery is 35–60 days depending on customization.

11. Manutenzione e supporto

- Preventive Maintenance Schedule

Regular checks on bearings, cinture, motori, and sensors. - Disponibilità pezzi di ricambio

Fast global shipping for critical components. - Diagnostica remota

Enabled via industrial routers and PLC diagnostics.

12. Pricing & Investment Return

| Capacità | Approximate Price (Dollaro statunitense) |

|---|---|

| 100–200 kg/h | $35,000 - $60,000 |

| 300–500 kg/h | $70,000 - $120,000 |

| 800–1000 kg/h | $150,000 - $220,000 |

| 1500 kg/h+ | $250,000 and above |

ROI Period: In genere 12 A 24 months depending on scale and market conditions.

13. Tendenze del mercato & Future Outlook

- Crescente domanda di healthier biscuits (low sugar, gluten-free).

- Growing investments in smart factories E Industry 4.0.

- Increased export opportunities in Africa, il Medio Oriente, e l'America Latina.

14. Conclusione: Build Your Biscuit Factory with Confidence

A fully automatic linea di produzione di biscotti empowers food manufacturers to deliver high-quality products at scale with consistency, igiene, and flexibility. Whether you are starting a biscuit plant or upgrading your facility, investing in modern biscuit production technology is the cornerstone of long-term profitability.

Ready to take the next step? Contact us for a tailored proposal, layout design, and quotation.