Les rouleaux de printemps sont l'une des collations les plus appréciées du monde, apprécié pour leur texture nette et leur délicieuse garnitures. Pour les restaurants, entreprises de restauration, et fabricants d'aliments, produisant cohérent, Les emballages de rouleaux de printemps de haute qualité sont un défi s'il est fait manuellement. C'est là qu'un Machine d'emballage de rouleaux de printemps devient essentiel. Cet équipement de transformation alimentaire avancé automatise la production d’emballages, Assurer l'efficacité, hygiène, et la rentabilité.

Nous allons approfondir tout ce que vous devez savoir sur machines à rouleau de printemps-leurs caractéristiques, avantages, principe de fonctionnement, Spécifications techniques, et comment ils peuvent transformer votre entreprise alimentaire.

Qu'est-ce qu'une machine d'emballage de rouleaux de printemps?

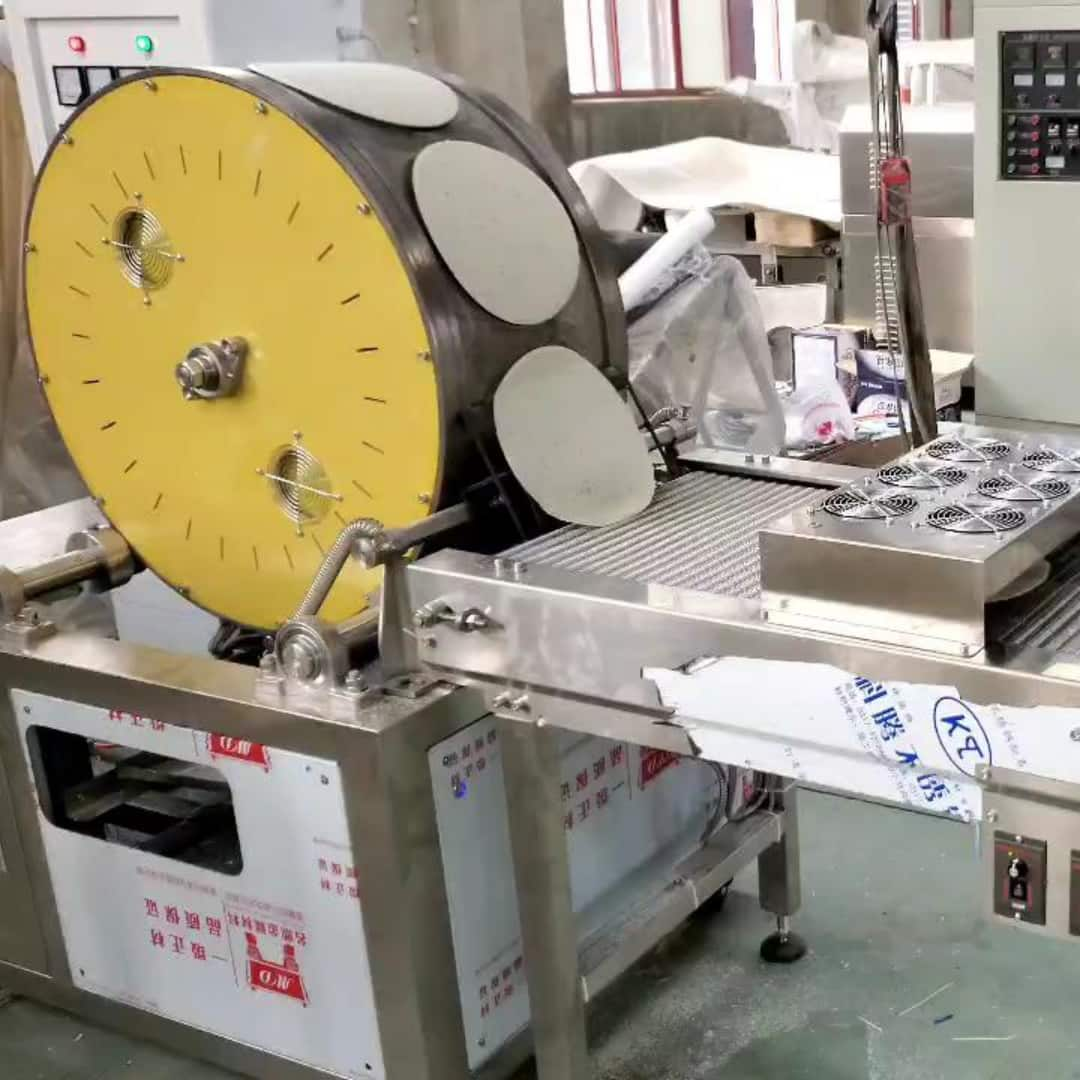

UN machine d'emballage de rouleaux de printemps est une machine de transformation des aliments conçue pour produire des, rond, et feuilles de pâtisserie uniformes (emballages) utilisé pour faire des rouleaux de printemps, samoussas, boulettes, et d'autres collations similaires. Traditionnellement, fabriquer ces emballages à la main nécessite des compétences, temps, et cohérence. Une machine automatise le processus, permettant une production en grand volume avec un minimum de main d'œuvre.

La machine est largement utilisée dans:

- Usines de transformation des aliments

- Fournisseurs de produits surgelés

- Hôtels et restaurants très demandés

- Entreprises de restauration

Avec cette machine, les entreprises peuvent répondre à la demande croissante des consommateurs tout en maintenant les normes de qualité.

Pourquoi investir dans une machine de fabrication d'emballage de rouleaux impériaux?

L'achat d'un machine d'emballage de rouleaux de printemps est plus qu’une simple mise à niveau d’équipement : c’est un investissement dans l’efficacité et l’évolutivité. Voici quelques raisons pour lesquelles les entreprises du secteur alimentaire font le changement:

- Cohérence de la qualité

Les emballages fabriqués à la main varient souvent en épaisseur et en taille, ce qui peut affecter le produit final. Une machine garantit l’uniformité. - Capacité de production élevée

Selon le modèle, les machines peuvent produire des centaines, voire des milliers d'emballages par heure. - Économies de coûts de main-d'œuvre

La production manuelle d’emballages demande beaucoup de main d’œuvre. Une machine réduit le besoin de personnel supplémentaire. - Hygiène et sécurité alimentaire

La machine minimise le contact direct avec les mains, assurer le respect des réglementations en matière de sécurité alimentaire. - Versatilité

Hormis les rouleaux de printemps, la machine peut produire des feuilles de samosa, emballages de lumpia, peaux de boulettes, et même des crêpes.

Comment fonctionne une machine d'emballage de rouleaux de printemps?

Comprendre le principe de fonctionnement d'une machine d'emballage de rouleaux de printemps aide les entreprises à le gérer efficacement.

- Préparation de la pâte

Farine, eau, et parfois l'amidon est mélangé pour former une consistance lisse, pâte sans grumeaux. - Système d'alimentation automatique

La pâte est pompée dans le système d’épandage de la machine. - Chauffage & Pâtisserie

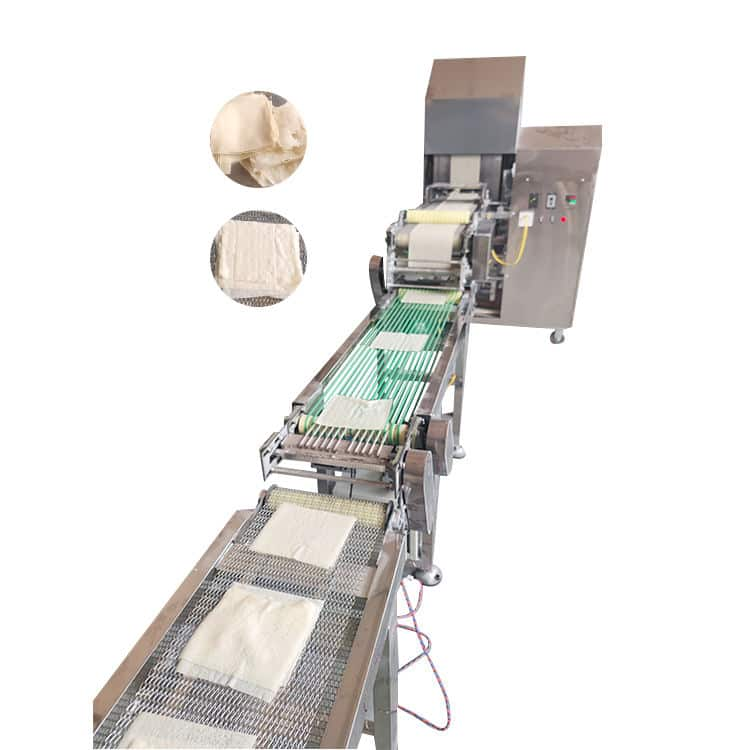

La pâte est répartie uniformément sur un tambour ou une plaque rotative chauffée. En quelques secondes, il forme une fine feuille cuite. - Coupe & Mise en forme

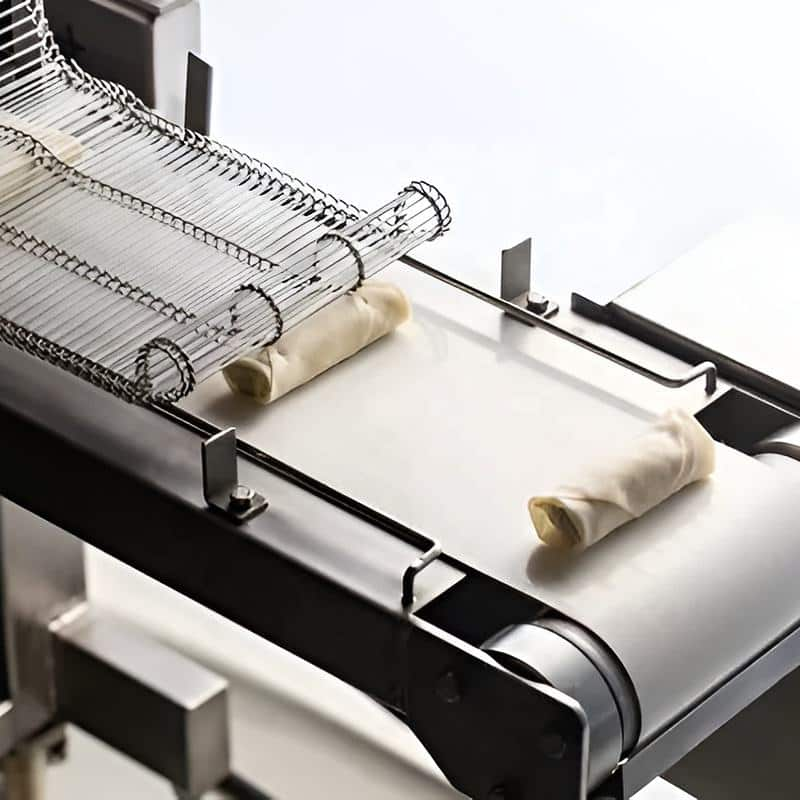

La feuille est automatiquement découpée dans les formes souhaitées : ronde, carré, ou rectangulaire, selon les besoins de production. - Empilement & Compte

Les emballages finis sont empilés et comptés automatiquement, prêt à être emballé ou utilisé immédiatement.

Principales caractéristiques de la machine d'emballage automatique de rouleaux de printemps

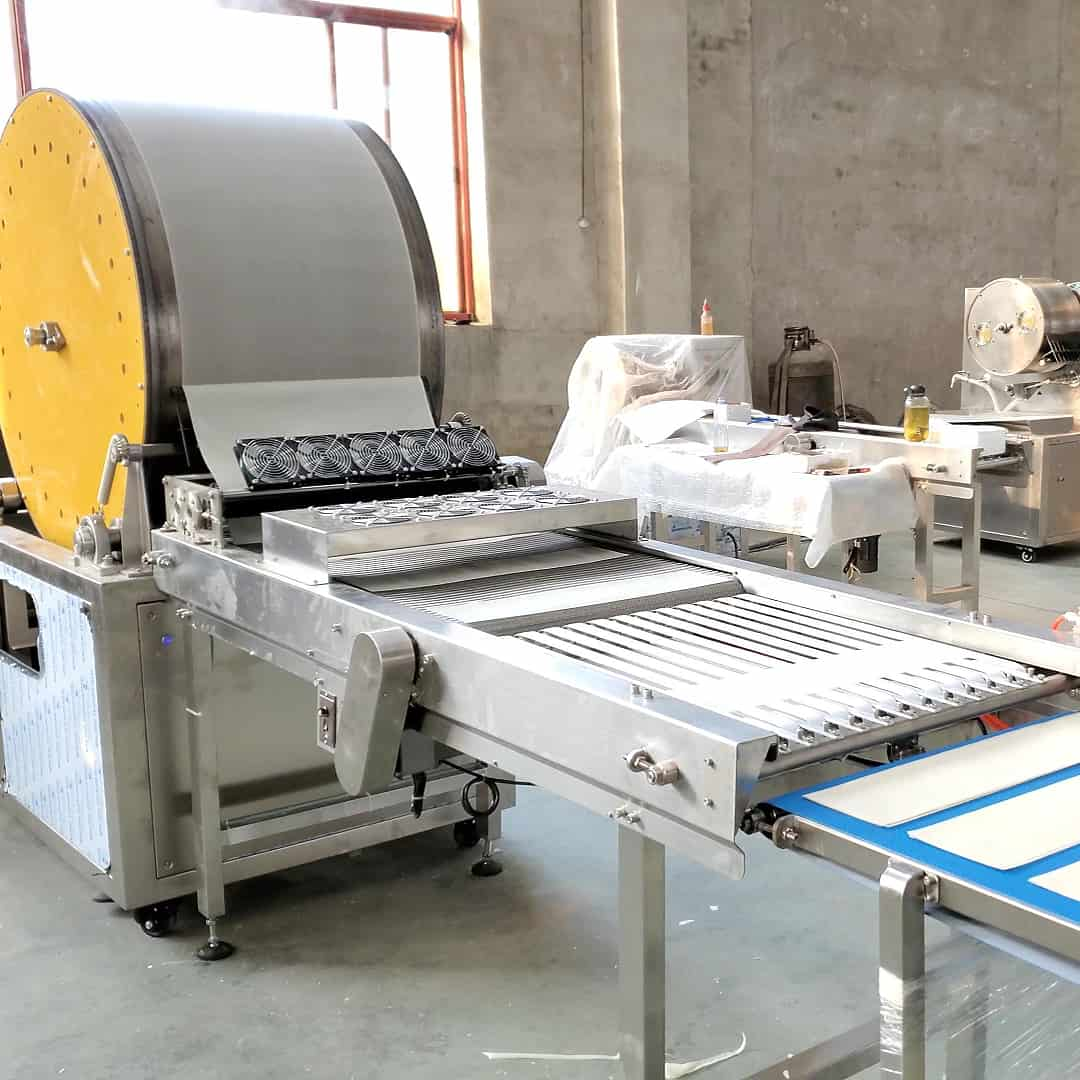

Moderne machines automatiques d'emballage de rouleaux de printemps sont dotés d'une technologie avancée qui garantit un fonctionnement convivial et un rendement maximal. Certaines fonctionnalités incluent:

- Construction en acier inoxydable (de qualité alimentaire, résistant à la rouille, facile à nettoyer)

- Épaisseur d'emballage réglable (généralement 0,3 mm à 1,2 mm)

- Plusieurs options de forme (rond, carré, rectangle)

- Système de contrôle de la température (chauffage précis pour une cuisson uniforme)

- Coupe automatique & Empilement

- Efficacité énergétique (le système de chauffage optimisé réduit la consommation d'énergie)

Paramètres techniques de la machine d'emballage de rouleaux de printemps

Ci-dessous est un général tableau des paramètres techniques pour une machine commerciale d'emballage de rouleaux de printemps:

| Modèle | Capacité (PC / HR) | Taille de l'emballage (mm) | Épaisseur de l'emballage (mm) | Pouvoir (kW) | Dimensions (mm) | Poids (kilos) |

|---|---|---|---|---|---|---|

| SRW-300 | 3000 | 100–200 | 0.3–1,0 | 6.5 | 1200×800×1300 | 350 |

| SRW-600 | 6000 | 100–220 | 0.3–1,2 | 9.0 | 1500×1000×1500 | 500 |

| SRW-1000 | 10,000 | 100–250 | 0.3–1,2 | 12.5 | 1800×1200×1600 | 750 |

Note: Les spécifications peuvent varier en fonction du fabricant et des besoins de personnalisation.

Types de machines d'emballage de rouleaux impériaux

Il existe différents modèles en fonction de l'échelle de production et des exigences de l'entreprise:

1. Machine d'emballage de rouleaux de printemps à petite échelle

Idéal pour les restaurants, petits services de restauration, ou des startups. Compact, facile à utiliser, et abordable.

2. Machine d'emballage semi-automatique de rouleaux de printemps

Nécessite une assistance manuelle dans certaines étapes, adapté à une production à moyenne échelle.

3. Machine d'emballage de rouleaux de printemps entièrement automatique

Gère l’ensemble du processus : alimentation, pâtisserie, coupe, et empilage : idéal pour les usines alimentaires ayant une demande de production élevée.

Avantages de la machine d'emballage de rouleaux de printemps entièrement automatique

- Opération par une seule personne – Facile à gérer avec un minimum de personnel.

- Grande vitesse & Efficacité – Peut produire des milliers d’emballages par heure.

- Options de personnalisation – Taille réglable, épaisseur, et forme.

- Durabilité – Longue durée de vie avec corps en acier inoxydable.

- Retour sur investissement – Retour sur investissement plus rapide grâce aux économies de main d’œuvre et à une production plus élevée.

Applications de la machine de fabrication d'emballage de rouleaux impériaux

Hormis les rouleaux de printemps, le machine d'emballage peut également produire:

- Feuilles de samosas

- Emballages de Lumpia

- Peaux de boulettes

- Emballages de wonton

- Crêpes ou Pancakes

Cette polyvalence en fait un incontournable pour les entreprises du secteur des produits surgelés et des snacks..

Prix de la machine d'emballage de rouleaux de printemps: Facteurs à considérer

Le prix de la machine d'emballage de rouleaux de printemps dépend de plusieurs facteurs:

- Capacité de production – Les machines de plus grande capacité sont plus chères.

- Niveau d'automatisation – Les modèles entièrement automatiques coûtent plus cher que les modèles semi-automatiques.

- Matériel & Qualité de construction – La construction en acier inoxydable augmente la durabilité mais aussi le coût.

- Options de personnalisation – Formes spécialisées, tailles, ou les fonctions affectent les prix.

En moyenne, les petits modèles peuvent coûter environ $3,000–8 000 $, tandis que les machines à grande échelle entièrement automatiques varient entre $15,000–50 000$ selon spécifications.

Comment choisir la meilleure machine d'emballage de rouleaux de printemps

Lors de la sélection d'un machine à pâtisserie pour rouleaux de printemps, Considérez ce qui suit:

- Besoins de production - Petit, moyen, ou capacité industrielle.

- Disponibilité de l'espace – Assurez-vous que la machine s’adapte à votre zone de production.

- Facilité d'utilisation – Recherchez des commandes conviviales.

- Service après-vente – Des fournisseurs fiables assurent l’installation, entraînement, et assistance à la maintenance.

- Efficacité énergétique – Économisez sur les coûts d’électricité grâce à des systèmes de chauffage avancés.

Conseils d'installation et d'entretien

- Placer la machine sur un plat, surface stable.

- Assurer les connexions électriques appropriées selon les spécifications.

- Nettoyer soigneusement la machine après chaque quart de production.

- Vérifiez régulièrement l'usure des plaques chauffantes et des bandes transporteuses..

- Lubrifier les pièces mobiles selon les recommandations du fabricant.

Avec des soins appropriés, un machine d'emballage de rouleaux de printemps peut durer 8 à 10 ans ou plus.

Machine d'emballage de rouleaux de printemps pour les usines alimentaires

Les usines alimentaires qui produisent des snacks surgelés en vrac peuvent grandement bénéficier d'un machine d'emballage de rouleaux de printemps entièrement automatique. Combiné avec la congélation, conditionnement, et machines à sceller, cela peut former un ligne de production complète de rouleaux de printemps, réduire les coûts et augmenter l’efficacité de la production.

Ligne de production d'emballages pour rouleaux impériaux

Pour les grands fabricants, un ligne de production d'emballages de rouleaux de printemps peut inclure:

- Machine à mélanger la pâte

- Machine d'emballage automatique

- Remplissage (en option pour la fabrication automatique de rouleaux de printemps)

- Machine à frire ou à congeler

- Machine d'emballage

Cette ligne intégrée aide les entreprises à produire des milliers de rouleaux de printemps par jour.

Pourquoi nous choisir comme fournisseur de machines d'emballage de rouleaux impériaux?

- Sur 20 années d'expérience dans les machines de transformation des aliments

- Solutions personnalisables pour répondre aux besoins de votre entreprise

- Construction en acier inoxydable de haute qualité pour la durabilité

- Prix directs usine compétitifs

- Assistance à la livraison et à l'installation à l'échelle mondiale

Questions fréquemment posées (FAQ)

1. La machine peut-elle fabriquer différentes tailles d'emballages?

Oui, la plupart des machines permettent d'ajuster le diamètre et l'épaisseur de l'emballage.

2. Est-ce difficile à utiliser?

Non. Avec une formation de base, une seule personne peut le faire fonctionner facilement.

3. Puis-je utiliser la machine pour des emballages de raviolis ou de samosas ??

Oui, avec de petits ajustements, la machine peut produire plusieurs types de feuilles.

4. Combien de temps prennent l'expédition et l'installation?

Généralement 2 à 6 semaines selon l'emplacement et le modèle.

5. Quelle est la période de garantie?

La plupart des machines sont livrées avec un 1–2 ans de garantie.

Pour l'avenir

UN machine d'emballage de rouleaux de printemps change la donne pour les entreprises alimentaires qui souhaitent produire des emballages de haute qualité à grande échelle. Que vous dirigiez un petit restaurant ou une grande usine de produits surgelés, investir dans la bonne machine garantit une qualité de produit constante, économies de coûts, et des bénéfices plus élevés.

En choisissant un fabricant fiable, vous obtenez non seulement une machine, mais également un partenaire à long terme dans votre parcours de production alimentaire.

Si vous êtes prêt à moderniser votre entreprise avec un machine d'emballage de rouleaux de printemps, contactez-nous aujourd'hui pour une solution sur mesure.