Quand les entreprises alimentaires se développent ou commencent à automatiser leur production, l'une des premières questions qui se pose est: "Quel est le prix d'une machine automatique à rouleaux impériaux?"

Il s'agit d'une question très pratique, mais la réponse dépend de plusieurs facteurs clés tels que la capacité, niveau d'automatisation, type de remplissage, marque, pays d'origine, et accessoires en option. Dans cet article, nous explorerons tout ce que vous devez savoir sur prix des machines automatiques à rouleaux de printemps, comment choisir le bon modèle pour votre entreprise, et ce que vous devez rechercher avant de faire un investissement.

🏭 1. Comprendre la machine automatique à rouleaux de printemps

Un machine automatique à rouleaux de printemps est un équipement spécialisé de transformation des aliments conçu pour produire des rouleaux de printemps en grande quantité et de taille constante., forme, et goûter. Il effectue plusieurs étapes automatiquement, y compris:

- Formation d'emballage

- Alimentation de remplissage

- Roulage et scellement

- Comptage et emballage (facultatif)

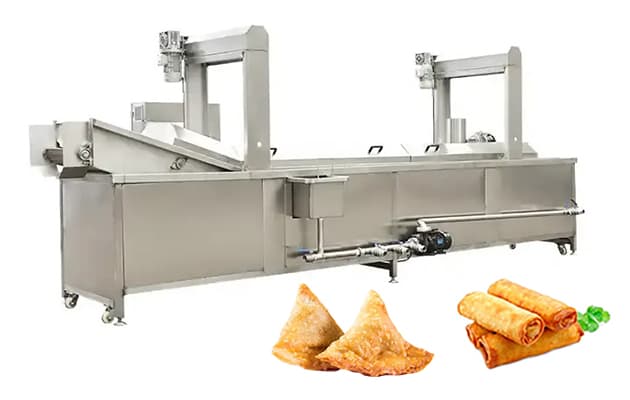

Il est largement utilisé dans les usines produisant des aliments surgelés, grignotine, ou des plats préparés. Ces machines peuvent produire non seulement des rouleaux de printemps à la chinoise mais également des rouleaux vietnamiens., samoussas, rouleaux de printemps, et même des petits pains pâtissiers selon les réglages.

💰 2. Gamme de prix générale des machines automatiques à rouleaux impériaux

Le prix d'une machine automatique à rouleaux impériaux peut varier considérablement en fonction de son niveau d'automatisation et de sa capacité de production.. Vous trouverez ci-dessous une référence générale:

| Type de machine | Capacité (PC / Hour) | Fourchette (USD) | Niveau d'automatisation |

|---|---|---|---|

| Petite machine à rouleaux de printemps semi-automatique | 500–1500 | $2,000–5 000$ | Remplissage manuel |

| Machine à rouleaux de printemps automatique et compacte | 2000–4000 | $6,000- 10 000 $ | Formage automatique des emballages |

| Machine à rouleaux de printemps automatique industrielle | 5000–8000 | $10,000–18 000 $ | Entièrement automatique |

| Grande ligne de production avec friteuse & emballage | 8000–15000+ | $20,000–60 000 $+ | Entièrement intégré |

👉 Résumé:

- Les petits magasins ou les restaurants locaux peuvent commencer avec un modèle semi-automatique à faible coût.

- Les usines de taille moyenne devraient envisager des machines entièrement automatiques pour réduire les coûts de main-d'œuvre.

- Les grands fabricants de produits alimentaires investissent généralement dans des lignes de production intégrées.

⚙️ 3. Facteurs clés qui affectent le prix de la machine

3.1 Capacité de production

Plus la production est élevée (morceaux par heure), plus le prix est élevé. Les machines conçues pour un usage industriel nécessitent des moteurs plus puissants, systèmes API avancés, et cadres en acier inoxydable pour gérer un fonctionnement continu.

3.2 Niveau d'automatisation

Une machine semi-automatique automatise uniquement la fabrication des emballages, tandis qu'un machine à rouleaux de printemps entièrement automatique effectue l'ensemble du processus, y compris le remplissage, pliant, et scellage. Cette différence peut doubler voire tripler le prix.

3.3 Système et matériel de remplissage

Si vos rouleaux de printemps contiennent des garnitures mélangées comme des légumes, nouilles en verre, ou viande hachée, tu auras besoin d'un système de remplissage personnalisé. Les systèmes de remplissage pneumatiques avec contrôle précis du volume sont plus chers que les systèmes manuels.

3.4 Technologie de formage d'emballage

Certains fabricants utilisent des tambours chauffants; d'autres utilisent des bandes de cuisson continues. Machines avec réglage automatique de l'épaisseur, contrôle de la température, et le revêtement antiadhésif coûte généralement plus cher.

3.5 Matériel de construction

De qualité alimentaire 304 acier inoxydable est standard, mais si l'ensemble du cadre et du système d'alimentation est en acier inoxydable, le coût sera plus élevé. Cela garantit l’hygiène et la durabilité à long terme.

3.6 Marque et pays d'origine

Machines fabriquées en Chine et Taïwan sont souvent plus rentables que ceux fabriqués au Japon ou en Europe. Cependant, de grandes marques chinoises comme Machine alimentaire DT allier qualité et prix abordable, ce qui les rend idéaux pour les acheteurs internationaux.

3.7 Équipement optionnel

L'ajout d'équipements supplémentaires tels qu'un friteuse, convoyeur de refroidissement, machine d'emballage, ou Congélateur IQF augmentera considérablement l’investissement total.

🔍 4. Exemples de prix typiques (2025 Mise à jour)

Pour vous donner une idée plus claire, voici des approximations prix du marché à compter de 2025:

| Modèle | Capacité | Caractéristiques | Prix estimé |

|---|---|---|---|

| DT-SRM2000 | 2000 PC / Hour | Conception compacte, emballeuse automatique, remplissage manuel | $6,000–8 000 $ |

| DT-SRM4000 | 4000 PC / Hour | Formage entièrement automatique, pliant, scellage | $10,000–12 000$ |

| DT-SRM8000 | 8000 PC / Hour | Contrôle PLC industriel, remplissage automatique, double ceinture | $15,000–20 000$ |

| Ligne complète DT | 12000 PC / Hour | Ligne complète avec friteuse, convoyeur, emballage | $35,000–60 000 $+ |

💡 Note: Ce sont des prix d'usine approximatifs (Exw). Frais supplémentaires comme l'expédition, douane, et l'installation varient selon les pays.

🧩 5. Ce qui est inclus dans le prix?

Lorsque vous recevez un devis d'un fabricant professionnel tel que Machine alimentaire DT, le prix standard comprend généralement:

- Machine de formage de rouleaux de printemps principale

- Système de chauffage (gaz ou électrique)

- Panneau de commande avec PLC

- Trémie de remplissage & buses

- Pièces de rechange et outils

- Manuel d'utilisation

- Garantie d'un an

Les éléments facultatifs peuvent inclure:

- Friteuse continue

- Convoyeur de refroidissement

- Compteur automatique

- Machine d'emballage

Avant de confirmer la commande, vérifiez toujours ce qui est inclus et si l’installation ou la formation fait partie de l’offre.

🌍 6. Comparaison des prix par pays

| Pays | Niveau de prix | Caractéristiques notables |

|---|---|---|

| Chine | ★★★ Abordable | Forte performance, conception personnalisable |

| Japon | ★★★★★ Cher | Précision haut de gamme, adapté aux usines de produits surgelés haut de gamme |

| Europe | ★★★★☆ Élevé | Conforme aux normes CE et HACCP |

| Inde | ★★ Faible | Fonctions de base, automatisation limitée |

| Thaïlande / Vietnam | ★★★ Modéré | Machines chinoises souvent rebaptisées |

Pour la plupart des acheteurs, Machines à rouleaux de printemps fabriquées en Chine offrir le meilleur équilibre entre prix, qualité, et service après-vente.

🧮 7. Coûts supplémentaires à considérer

Lors de la planification de votre budget, n'oubliez pas d'inclure:

- Expédition et fret: Selon l'emplacement, le fret maritime peut coûter entre 500 et 2 000 $.

- Droits de douane et taxes à l'importation: Varie selon le pays (5%–20%).

- Conversion de tension ou type de prise: Peut nécessiter un ajustement aux normes locales.

- Formation des opérateurs: Certains fabricants proposent une formation en ligne gratuite.

- Entretien et pièces de rechange: Généralement peu coûteux pour les machines chinoises.

Tous ces facteurs affectent votre coût total d'investissement, pas seulement le prix de la machine.

🧠 8. Comment choisir la bonne machine automatique à rouleaux de printemps

En comparant les prix, ne vous concentrez pas uniquement sur le coût – évaluez valeur et performance. Voici des conseils pratiques:

- Définissez vos besoins en capacité:

Choisissez un modèle qui répond à vos objectifs de production mais laisse une marge de croissance. - Vérifier les matériaux de la machine:

Assurez-vous que toutes les pièces en contact avec les aliments sont fabriquées en 304 acier inoxydable. - Confirmer la compatibilité de remplissage:

Demandez si votre remplissage spécifique (légume, viande, nouilles en verre, etc.) peut être traité en douceur. - Demander une vidéo ou une démo en direct:

Des fabricants fiables comme DT Food Machine proposent des vidéos de test ou des démonstrations en ligne. - Renseignez-vous sur le support après-vente:

Garantie, Disponibilité des pièces de rechange, et le guidage à distance sont essentiels pour une utilisation à long terme. - Comparez l'efficacité énergétique:

Les modèles chauffés au gaz sont généralement moins chers à faire fonctionner que les modèles électriques.

🔧 9. Coûts d'entretien et de fonctionnement

Même si le prix initial est important, le coût d'exploitation affecte également votre rentabilité.

Les machines automatiques à rouleaux impériaux ont généralement de faibles coûts de maintenance si elles sont utilisées correctement. Les points d'entretien clés comprennent:

- Nettoyage du tambour d'enrubannage après chaque lot

- Contrôle de l'usure des bandes transporteuses

- Lubrifier régulièrement les pièces mobiles

- Remplacement périodique des éléments chauffants

Un entretien adéquat prolonge non seulement la durée de vie de la machine, mais améliore également l'efficacité de la production, vous permettant ainsi d'économiser de l'argent au fil du temps..

📈 10. Retour sur investissement (Retour de retour)

Calculons un exemple simple de retour sur investissement:

- Coût de la machine: $12,000

- Sortir: 4000 PC / Hour

- Production quotidienne: 32,000 pièces (8 heures)

- Bénéfice par pièce: $0.05

👉 Bénéfice quotidien: 32,000 × 0.05 = $1,600/jour

Vous pouvez récupérer le coût total en moins de 10 jours ouvrables — ce qui en fait l'un des investissements les plus rentables dans l'industrie alimentaire.

🤝 11. Pourquoi choisir DT Food Machine

Machine alimentaire DT est un fabricant professionnel de machines à rouleau de printemps automatiques et lignes de transformation des aliments avec des années d'expérience dans l'exportation vers l'Asie, Europe, le Moyen-Orient, et Amérique du Sud.

Avantages de choisir DT Food Machine:

- Prix direct usine

- Capacité et taille personnalisables

- Construction en acier inoxydable

- Options de tension internationales

- 24-assistance en ligne d'une heure

- Vidéos et manuels d'utilisation gratuits

- Certifié CE et approuvé ISO

Nous fournissons à la fois des machines autonomes et des lignes de production de rouleaux de printemps entièrement automatiques., aider nos clients à construire des usines de produits surgelés efficaces dans le monde entier.

📦 12. Comment obtenir un devis

Si vous souhaitez connaître exactement Prix de la machine à rouleaux de printemps automatique, contactez simplement notre équipe commerciale avec ces coordonnées:

- Capacité de production souhaitée (PC / Hour)

- Type de remplissage que vous prévoyez d'utiliser

- Exigences de tension et de puissance

- Besoin d'une friteuse ou d'un système d'emballage

- Port ou pays de destination

Dans 24 heures, notre équipe préparera un devis personnalisé avec spécifications de la machine, vidéos, et délai de livraison estimé.

📝 Prix d'une machine automatique à rouleaux impériaux

Le prix d'une machine automatique à rouleaux de printemps se pose de $6,000 à $60,000+, en fonction de la capacité de production, niveau d'automatisation, et équipement supplémentaire. Pour la plupart des usines alimentaires de taille moyenne, une machine fiable dans le $10,000–20 000$ la gamme est idéale – équilibrer les coûts, efficacité, et valeur à long terme.

En choisissant un fabricant de confiance comme Machine alimentaire DT, vous pouvez garantir non seulement des prix compétitifs mais également une excellente qualité, service mondial, et support technique.

Si vous êtes prêt à moderniser votre ligne de production ou à démarrer une nouvelle entreprise de rouleaux de printemps surgelés, un machine automatique à rouleaux de printemps est la clé d’une productivité et d’une rentabilité accrues.