Potato chips are among the most popular snacks worldwide. From supermarkets and restaurants to street vendors, the demand for crispy potato chips never stops growing. For businesses planning to enter this market, Choisir le droit potato chips machine is the first and most important step. One of the key factors in making this investment decision is the potato chips machine price. Dans cet article, we will explore the price range of potato chips machines with capacities between 100kg and 1000kg per hour, analyze what affects the cost, and explain how to select the right equipment for your production needs.

1. Introduction to Potato Chips Machines

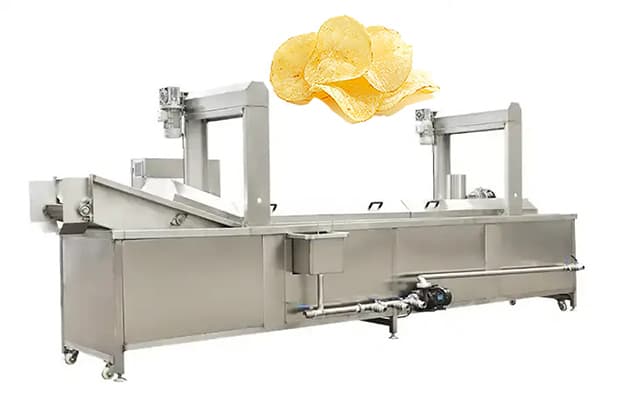

UN potato chips machine is a food processing system designed to wash, peel, slice, fry, season, and package potatoes into crispy chips. En fonction de l'ampleur de la production, machines can be small semi-automatic units or large fully automatic production lines.

Pour les petites entreprises, un 100kg/h potato chips machine may be sufficient. But for medium or large factories, capacities of 300kg/heure, 500kg/heure, or even 1000kg/h are more suitable. Each level of production capacity comes with different costs, Caractéristiques, and requirements.

2. Why Potato Chips Machine Price Matters

When starting or upgrading a potato chips business, machine price is not just a number. It represents:

- Investissement en capital: The upfront money needed to begin production.

- Production Capability: Higher price often reflects larger capacity and advanced automation.

- Long-Term Efficiency: Well-designed machines consume less energy and reduce waste.

- Product Quality: Better machines ensure consistent taste, texture, et l'apparence.

Ainsi, understanding the potato chips machine price is essential to balance budget, efficacité, and product quality.

3. Potato Chips Machine Capacity Range: 100kg-1000kg

Here is an overview of typical machine capacities and what they mean for your business:

| Machine Capacity | Adapté à | Typical Users | Fourchette (USD) |

|---|---|---|---|

| 100kg/heure | Petits commerces, local restaurants, startups | Local snack producers, new entrepreneurs | $5,000 - $15,000 |

| 200-300kg/heure | Medium production | Regional distributors, growing businesses | $15,000 - $35,000 |

| 500kg/heure | Medium-large factories | Snack brands, contract manufacturers | $35,000 - $60,000 |

| 1000kg/heure | Grandes installations industrielles | International brands, high-volume suppliers | $60,000 - $120,000 |

Note: Prices vary depending on machine design (semi-automatic vs fully automatic), matériel (stainless steel quality), efficacité énergétique, et personnalisation.

4. Key Factors Affecting Potato Chips Machine Price

4.1. Niveau d'automatisation

- Machines semi-automatiques: Lower cost but require manual labor.

- Machines entièrement automatiques: Higher investment but reduce labor costs and ensure continuous production.

4.2. Matériel de machine

- De haute qualité acier inoxydable 304/316 ensures food safety and longer durability.

- Cheaper materials reduce cost but may lead to hygiene or corrosion issues.

4.3. Capacité de production

- A 100kg/h machine is compact and affordable.

- A 1000kg/h system requires larger equipment, more advanced controls, and higher energy supply, thus increasing price.

4.4. Technologie & Caractéristiques

- Automatic frying systems with oil filtration.

- Continuous washing and peeling machines.

- Contrôle numérique de la température.

- Integrated seasoning and packaging lines.

The more advanced the features, plus le prix est élevé.

4.5. Source d'énergie

- Machines can be powered by électricité, gaz, ou diesel.

- Gas-fired systems are often cheaper in terms of running cost, but initial price may be higher.

5. Cost Breakdown of a Potato Chips Production Line

When calculating potato chips machine price, it’s helpful to understand the cost distribution within a production line:

- Lavage & Peeling Unit - 10-15% of total cost.

- Slicing Machine - 5-10%.

- Machine de blanchiment - 10-15%.

- Déshydratation & Drying Unit - 5-10%.

- Friture - 25-35% (most expensive part).

- Dé-pétrole & Circuit de refroidissement - 5-10%.

- Machine à assaisonner - 5-10%.

- Machine d'emballage - 15-20%.

6. Potato Chips Machine Price Comparison: 100kg vs 1000kg

100kg/h System

- Prix: $5,000 - $15,000

- Best for small businesses or pilot projects.

- Requires more manual labor.

500kg/h System

- Prix: $35,000 - $60,000

- Balanced solution for medium-sized companies.

- Good efficiency with moderate investment.

1000kg/h System

- Prix: $60,000 - $120,000

- Designed for large-scale, 24/7 opérations.

- Fully automated, with oil filtration and advanced controls.

7. Coûts supplémentaires à considérer

Besides the machine price, businesses should plan for:

- Installation & Entraînement: $2,000 - $10,000 depending on complexity.

- Expédition & Customs: Varie selon le pays.

- Des pièces de rechange & Entretien: Annual budget of 5-10% of machine cost.

- Consommation d'énergie: Electricity or gas bills.

- Factory Setup: Approvisionnement en eau, oil storage, ventilation, and workspace design.

8. Retour de retour (Retour sur investissement) of Potato Chips Machines

A potato chips business can be highly profitable. Considérons un exemple:

- Raw Potato Cost: $0.30/kilos

- Selling Price of Chips: $3.00/kilos

- Yield: 1kg potato = 0.35kg chips

- Marge bénéficiaire: Around $0.70 - $1.20 per kg of potato used

With a 500machine kg / h, a factory can process 4,000kg per day (8 heures). That equals 1,400kg of chips daily, with potential profits exceeding $1,000 per day. Cela signifie que l'investissement de la machine peut être récupéré dans 6-12 mois.

9. Comment choisir la bonne machine à croustilles de pomme de terre

When evaluating potato chips machine price, do not just look at numbers. Considérer:

- Your Production Scale: Start small or go large depending on market size.

- Besoins d'automatisation: Reduce labor cost with full automation if budget allows.

- Normes de qualité: Choose food-grade stainless steel for hygiene and export compliance.

- Supplier Reputation: Work with reliable manufacturers that provide installation, entraînement, et service après-vente.

- Personnalisation: Some suppliers offer customized solutions for seasoning flavors, packaging design, and energy sources.

10. Future Trends in Potato Chips Machines

- Efficacité énergétique: Machines with lower oil and electricity consumption.

- Digital Monitoring: IoT-enabled machines to track production in real time.

- Healthier Chips: Low-oil frying and baked chips technology.

- Compact Designs: Space-saving models for urban food factories.

These innovations may slightly increase the potato chips machine price but will bring long-term savings and higher consumer demand.

11. Pourquoi choisir DT Food Machine

If you are planning to invest in a potato chips machine (100kg-1000kg capacity), price is an important factor—but reliability, durabilité, and service matter just as much.

À Machine alimentaire DT, we specialize in designing and supplying high-quality potato chips machines for businesses of all sizes. Our machines are made of food-grade stainless steel, equipped with advanced automation, and designed for long-term performance.

Whether you need a 100machine kg / h for a startup or a 1000Kg / H Ligne entièrement automatique for large-scale production, Machine alimentaire DT provides the right solution with competitive pricing, aide à l'installation, and excellent after-sales service.

👉 DT Food Machine – Your Professional Potato Chips Machine Supplier