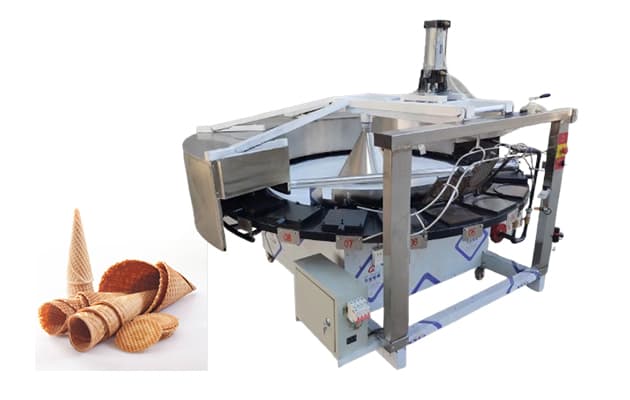

Mise en place d'un Machine à cornets de crème glacée- qu'il s'agisse d'un fabricant de cornets de gaufres, machine à cornets de sucre, machine de cuisson de cônes de gaufrettes, ou un entièrement ligne de production automatique de cornets de glace—est l’une des étapes les plus importantes avant de commencer la fabrication des cônes. Une machine correctement installée garantit une température de cuisson stable, couleur uniforme du cône, grande efficacité, et longue durée de vie.

De nombreux acheteurs achètent l'équipement mais ne connaissent pas la procédure d'installation correcte.. Cela conduit souvent à une cuisson inégale, erreurs de machines, ou qualité de cône incohérente. Ce guide vous guidera à travers chaque étape de l'installation, de la préparation de l'atelier à l'étalonnage et à la production des tests.

1. Pourquoi une bonne installation est cruciale

Une haute qualité Machine à cornets de crème glacée peut fonctionner 24 heures en continu, mais seulement lorsqu'il est correctement installé.

Une configuration appropriée garantit:

- Répartition stable de la chaleur

- Texture et croustillant optimaux du cône

- Baisse de la consommation de gaz ou d'électricité

- Flux de production plus fluide

- Coût de maintenance réduit

- Moins de temps d'arrêt

- Qualité cohérente du produit

Une installation incorrecte peut entraîner:

- Cônes brûlés ou insuffisamment cuits

- Couleur inégale du cône

- Fuite de pâte

- Consommation excessive de carburant

- Cônes cassés ou fissurés

- Interruptions de production

Donc, comprendre le processus de configuration correct est essentiel pour tout fabricant démarrant un entreprise de production de cônes.

2. Préparation de l'atelier avant l'installation

Avant de placer le fabricant de cônes industriels, préparer l'atelier selon les exigences de la machine.

2.1 Exigences spatiales

Une norme four rotatif à cornets de glace ou machine de cuisson de cônes de gaufrettes besoins:

- Libérer de l'espace autour de la machine: 1–1,5 mètres pour l'entretien

- Un appartement, terrain plat

- Espace de flux de travail fluide pour les opérateurs

- Local pour mixeur à pâte, convoyeur, et station d'emballage

Pour une production entièrement automatique:

- Espace supplémentaire pour le convoyeur de refroidissement

- Système de comptage de cônes

- Rubrique Emballage

2.2 Exigences environnementales

La production de cornets de glace nécessite un environnement contrôlé:

- Température: 10–35°C

- Humidité: <75%

- Sans poussière et sec

- Bonne circulation de l'air

- Pas de lumière directe du soleil sur la zone de cuisson

Une humidité élevée peut ramollir les cônes ou causer des problèmes de stockage.

2.3 Préparation de l'approvisionnement en énergie

Selon le type de machine:

Machines à cornets de crème glacée à chauffage au gaz

- Conduite de GPL ou de gaz naturel

- Régulateur de pression de gaz

- Vanne de gaz antidéflagrante

- Tuyaux en acier ou en caoutchouc certifié

- Une bonne ventilation

Machines à cornets de crème glacée à chauffage électrique

- 380V triphasé

- Tension stable (±5%)

- Mise à la terre appropriée

- Stabilisateur de tension (recommandé pour l'Afrique, l'Amérique latine, Asie du Sud)

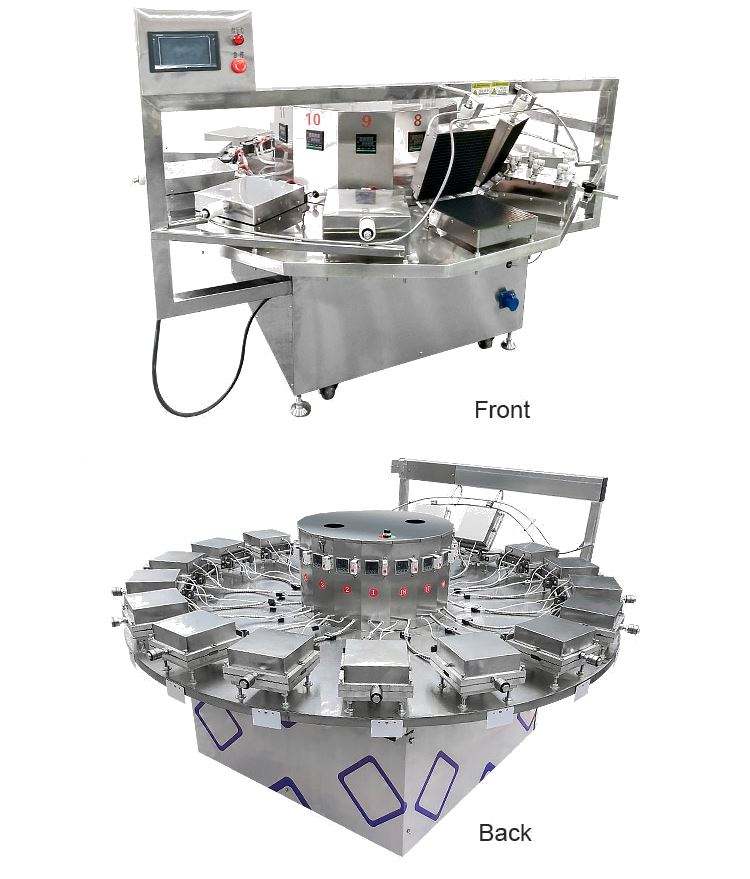

3. Vérification de la machine à cornets de crème glacée avant l'installation

Lorsque vous recevez le matériel, inspecter les composants suivants:

- Moules à cuisson / assiettes

- Brûleurs à gaz ou tubes chauffants

- Armoire électrique

- Chaîne de transmission

- Moules à rouler les cônes

- Pompe à pâte

- Panneau de contrôle IHM/automate

- Convoyeur de refroidissement

- Des pièces de rechange (ressorts, ceintures, capteurs, fusibles)

Vérifiez les dommages dus au transport ou les attaches desserrées.

4. Étape par étape: Comment configurer une machine à cornets de crème glacée

Vous trouverez ci-dessous le processus de configuration complet pour les deux fabricants de cônes semi-automatiques et lignes de production industrielles automatiques de cônes.

Étape 1: Positionner correctement la machine

Placez le machine à fabriquer des cornets de gaufres ou four de cuisson à cône de gaufrette rotatif sur une surface plane.

Exigences:

- Garder 1 mètre d'espace autour

- Utilisez une règle de niveau pour assurer la stabilité

- Évitez les sols humides ou inégaux

- Laissez de l'espace pour l'alimentation en pâte et le système de refroidissement

Un placement correct empêche les vibrations et assure une cuisson uniforme.

Étape 2: Connectez le système de gaz (Le cas échéant)

Au gaz Machines à cône de sucre nécessitent une pression stable.

2.1 Connexion de pipeline

Utiliser:

- Gazoduc indépendant

- Régulateur haute pression

- Tubes en acier

- Ruban d'étanchéité en téflon

2.2 Exigences en matière de pression de gaz

- GPL: 30–50 mbar

- Gaz naturel: 15–25 mbar

2.3 Inspection de sécurité

- Appliquez de l'eau savonneuse sur les joints pour vérifier les fuites.

- Assurez-vous que le ventilateur d’extraction fonctionne

- Installer un arrêt de gaz d'urgence

Ne démarrez jamais les brûleurs tant que le test de fuite n'est pas terminé..

Étape 3: Connectez le système électrique

Même pour les appareils de chauffage au gaz, les commandes nécessitent de l'électricité.

Vérifiez les éléments suivants:

- Fil de terre

- Interrupteur d'alimentation principal

- Câblage de l'armoire de commande

- Connexions relais

- Fonction d'arrêt d'urgence

- L'automate/l'IHM démarre avec succès

Exigences électriques

- Triphasé 380V

- Tension stabilisée

- Mise à la terre sécurisée (<4Oh)

Étape 4: Installez le mélange de pâte & Système d'alimentation

Ton machines de traitement de cornets de crème glacée a besoin d’un système d’alimentation en pâte cohérent.

4.1 Mélangeur de pâte

Préparez la pâte avec:

- Farine

- Sucre

- Eau

- Huile

- Arôme

Mélanger pour 10–20 minutes pour la cohérence.

4.2 Connecter la pompe à pâte

- Utilisez des tuyaux de qualité alimentaire

- Vérifier les fuites

- Assurer une aspiration et une sortie fluides

4.3 Ajuster la quantité de remplissage (Dosage)

Le dosage détermine l'épaisseur du cône:

- Petits cônes: 8–15g

- Cônes moyens: 12-25g

- Grands cônes: 20–40g

Ajuster via PLC ou vanne mécanique selon le modèle.

Étape 5: Essai à sec (Pas de pâte)

Avant d'ajouter la pâte, exécuter le fabricant de cônes industriels vide.

Vérifier:

- Mouvement de la chaîne de transmission

- Rotation de la plaque

- État de la flamme du gaz

- Réponse du chauffage électrique

- Bruit du moteur

- Augmentation de la température

Le préchauffage prend généralement 8–12 minutes.

Étape 6: Ajoutez de la pâte et démarrez la production de tests

Une fois préchauffé, commencer le premier lot de tests.

- Démarrer le système de dosage

- Laisser la pâte entrer dans les moules

- Observer la qualité de la cuisson

- Vérifier l'uniformité de la couleur du cône

- Ajuster l'épaisseur si nécessaire

6.1 Contrôle de la température

Paramètres typiques:

| Type de cône | Température |

|---|---|

| Cônes de gaufrettes | 160–180°C |

| Cônes de sucre | 180–200°C |

| Chronomètres à gaufre | 190–220°C |

6.2 Temps de cuisson

Dépend du modèle:

- 45–90 secondes par cycle

Étape 7: Ajuster le système de roulement du cône

Le cône doit être parfaitement formé.

Vérifier:

- Fermeture de la pointe

- Épaisseur de paroi

- Précision de la forme

- Pas de fissures

Ajuster:

- Pression de roulement

- Alignement du moule

- Température du mandrin du cône

Étape 8: Refroidissement et stabilisation de l'humidité

Les cornets frais sont encore mous.

Le refroidissement se fait via:

- Tunnel de refroidissement de l'air

- Tapis roulant

- Plateau de refroidissement

Temps de refroidissement: 2–6 minutes.

Un refroidissement adéquat empêche la déformation.

Étape 9: Test de qualité final

Inspecter:

- Couleur du cône

- Croustillant

- Forme et angle

- Longueur

- Douceur

- Pas de bulles ni de trous

Ce n'est qu'après l'apparition d'une qualité stable que la production peut démarrer officiellement.

5. Problèmes courants et solutions lors de l'installation

Problème 1: Couleur inégale du cône

- Flamme de gaz inégale → nettoyer les brûleurs

- Mauvaise température → régler le chauffage

- Dosage irrégulier → calibrer la pompe

Problème 2: Fuite de pâte

- Plaques mal fermées → ajuster la charnière

- Trop de pâte → réduire le dosage

Problème 3: Les cônes se cassent facilement

- Pression trop élevée → ajuster le moule de formage

- Trop peu d'humidité → ajuster la recette

Problème 4: Cônes collant aux assiettes

- Moules sales → nettoyer & huile

- Plaques surchauffées → stabiliser la température

6. Exigences de sécurité

Sécurité du chauffage au gaz

- Vérifier les fuites quotidiennement

- Installer une vanne de coupure de gaz

- Maintenir la ventilation

- Gardez l'extincteur à proximité

Sécurité électrique

- Pas d'eau près de l'armoire de commande

- Évitez de surcharger

- Resserrer régulièrement les connexions

Sécurité des opérateurs

- Utilisez des gants résistants à la chaleur

- Ne contournez pas les capteurs de sécurité

- Gardez les vêtements éloignés des pièces mobiles

7. Exigences de formation pour les opérateurs

Chaque opérateur devrait apprendre:

- Rapports de mélange de pâte

- Contrôle de la température et du temps

- Alimentation correcte de la pâte

- Ajustement du moule

- Dépannage

- Procédures de nettoyage quotidiennes

Une bonne formation réduit considérablement le gaspillage et améliore l’efficacité.

8. Liste de contrôle des opérations quotidiennes

Avant de démarrer la machine:

- Préchauffer pendant 10 minutes

- Vérifiez le gaz ou l'électricité

- Confirmer le volume de dosage

- Nettoyer les moules

- Assurer la lubrification de la chaîne

- Testez la qualité du cône toutes les heures

9. Guide de maintenance

Tous les jours

- Assiettes propres

- Enlever les résidus

- Moules à cônes d'essuyage

Hebdomadaire

- Lubrifier les roulements

- Vérifier la tension de la chaîne

- Inspecter les brûleurs

Mensuel

- Inspection complète de la machine

- Test de sécurité

- Vérifiez le PLC et les capteurs

Avec une maintenance appropriée, ton Machine à cornets de crème glacée durera 8–12 ans ou plus.

Installer la machine à cornets de crème glacée

Mise en place d'un Machine à cornets de crème glacée, qu'il’c'est un fabricant de cornets de gaufres, machine de production de cornets de sucre, équipement industriel de cuisson de cône de gaufrette, ou ligne de fabrication automatique de cônes, est la clé pour garantir une production stable et des cônes de haute qualité.

En préparant correctement l’atelier, raccorder le gaz et l’électricité en toute sécurité, calibrage du dosage, ajustement des moules, tester les résultats de cuisson, et former les opérateurs, votre usine réalisera:

- Couleur du cône cohérente

- Grande efficacité

- Fonctionnement stable 24 heures sur 24

- Coût d’exploitation réduit

- Retour sur investissement plus rapide