Dans l'industrie moderne de la transformation des aliments, la demande de machine à éplucher l'ail commerciale les modèles ont considérablement augmenté. Ces machines sont conçues pour traiter rapidement de gros volumes d’ail, hygiéniquement, et avec un minimum de travail manuel. Cet article explore les aspects essentiels des machines à éplucher l'ail commerciales, y compris leurs types, applications de mots clés à longue traîne, principes de travail, Spécifications techniques, et conseils d'achat.

Introduction aux solutions industrielles d’épluchage de l’ail

Qu'est-ce qu'une machine à éplucher l'ail à usage commercial?

UN machine à éplucher l'ail commerciale le modèle fait référence à un dispositif automatisé utilisé pour retirer la peau des gousses d'ail en grandes quantités. Contrairement au peeling manuel, ces machines utilisent le flux d'air, friction, ou technologie de lame pour obtenir une efficacité élevée avec un minimum de dommages à l'ail.

Types de modèles commerciaux de machines à éplucher l’ail

Machine à éplucher l'ail pneumatique pour un traitement à grande vitesse

L'un des types les plus courants est le machine à éplucher l'ail pneumatique, qui utilise de l'air comprimé pour peler les gousses d'ail. Il est idéal pour les usines de transformation des aliments nécessitant des opérations rapides et continues..

Avantages:

- Aucune consommation d'eau

- Dommages minimes à l’ail

- Productivité élevée (jusqu'à 600-1000 kg/h)

Dissolvant de peau d'ail de type tambour pour la production en vrac

UN dissolvant de peau d'ail de type tambour comporte un baril rotatif où l'ail est renversé et pelé par friction. Ce type convient au milieu- aux environnements de production à grande échelle.

Éplucheur de gousses d'ail pour lignes de transformation

UN machine à éplucher les gousses d'ail est souvent intégré dans les lignes de transformation de l'ail avec le fractionnement, coupe, ou machines à sécher. Ceux-ci sont personnalisables en fonction de la capacité et de l'utilisation.

Principe de fonctionnement des unités commerciales de la machine à éplucher l'ail

Système de pelage alimenté par compresseur d'air

Dans les systèmes pneumatiques, les gousses d'ail sont introduites dans une chambre où de l'air à haute pression souffle sur la peau. Ces machines sont conçues pour séparer les peaux et les gousses d'ail en utilisant la dynamique du flux d'air et un cylindre d'épluchage interne..

Peeling mécanique par friction

Certains éplucheurs d'ail commerciaux utilisent des rouleaux en caoutchouc ou des brosses abrasives qui frottent doucement la peau de l'ail.. Bien que légèrement moins hygiéniques que les machines à air, ils offrent un rendement élevé et sont plus faciles à entretenir.

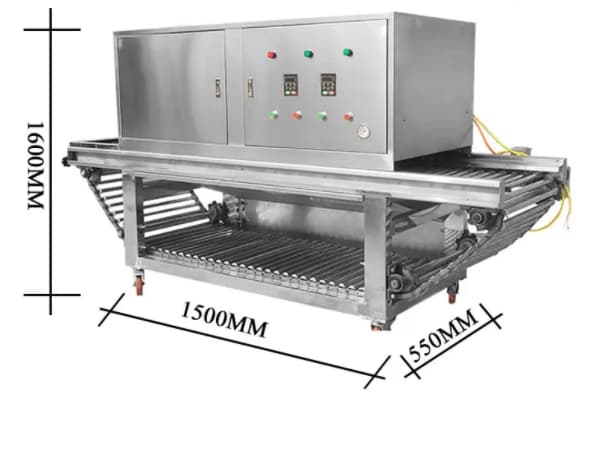

Spécifications techniques des machines à éplucher l'ail commerciales

| Modèle | Capacité (kg/heure) | Pouvoir (kW) | Exigence du compresseur d'air | Matériel | Taux de pelage (%) | Taille (mm) | Poids (kilos) |

|---|---|---|---|---|---|---|---|

| GP-100 | 100 | 0.2 | 0.75–1,0 MPa | SS 304 | ≥95% | 650×550×850 | 70 |

| GP-300 | 300 | 0.3 | 0.75–1,0 MPa | SS 304 | ≥96% | 950×650×1050 | 130 |

| GP-500 | 500 | 0.4 | 0.75–1,0 MPa | SS 304 | ≥96% | 1150×800×1200 | 180 |

| GP-1000 | 1000 | 0.75 | 0.75–1,0 MPa | SS 304 | ≥97% | 1350× 1000 × 1300 | 250 |

Toutes les machines à éplucher l'ail commerciales sont fabriquées en acier inoxydable de qualité alimentaire et sont conformes aux normes HACCP et CE..

Avantages de l'utilisation d'une machine à éplucher l'ail dans les cuisines commerciales

Gain de temps et de travail

L'épluchage manuel de l'ail peut demander beaucoup de travail. UN machine à éplucher l'ail commerciale l'unité peut se décoller jusqu'à 1000 kg d'ail par heure, réduisant le besoin de main-d’œuvre et réduisant les coûts opérationnels.

Haute efficacité et gaspillage minimal

Avec des taux de pelage supérieurs à 95%, ces machines garantissent que la quantité maximale d'ail est utilisable, avec un minimum de dégâts et de déchets.

Hygiène et sécurité

Les machines sont conçues pour respecter les normes de sécurité alimentaire, minimiser les risques de contamination, en particulier dans la production alimentaire commerciale.

Applications des machines commerciales d’élimination de la peau d’ail

Usines industrielles de transformation de l’ail

Usines produisant de la pâte d'ail, huile à l'ail, ou de l'ail déshydraté couramment utilisé machine à éplucher l'ail commerciale équipement comme processeur de premier étage.

Cuisines centrales et entreprises de restauration

Les cuisines centrales préparant des produits alimentaires prédécoupés ou pré-assaisonnés bénéficient des éplucheurs d'ail commerciaux en raison de leurs capacités de grand volume.

Fabricants de pâtes et de sauces à l'ail

Ces machines sont un élément clé de la chaîne de production de purée ou de sauce à l'ail, où l'ail pelé est essentiel.

Comment choisir la meilleure machine à éplucher l'ail pour un usage commercial

Évaluez votre volume de production

Choisissez une machine avec la capacité adaptée à votre entreprise. Les petits restaurants pourraient avoir besoin 100 kg/heure, tandis que les grandes plantes nécessitent 1000 kg / h ou plus.

Évaluer les besoins en énergie et en air

La plupart machines à éplucher l'ail commerciales nécessite un compresseur d'air. Assurez-vous que votre installation peut prendre en charge le compresseur’spécifications.

Recherchez la durabilité et la qualité des matériaux

Construction en acier inoxydable (SS 304 ou SS 316) est un incontournable pour l'hygiène et la longévité.

Pensez à la maintenance et aux pièces de rechange

Optez pour des modèles offrant un accès facile aux pièces détachées et à l'assistance à la maintenance., surtout s'il est utilisé quotidiennement dans des opérations commerciales.

Modèles commerciaux de machine à éplucher l'ail vs. Éplucheurs d'ail ménagers

| Fonctionnalité | Éplucheur commercial | Éplucheur domestique |

| Capacité | 100–1000 kg / h | 0.5–2 kg/heure |

| Source d'alimentation | Électrique + Air | Moteur manuel ou petit moteur électrique |

| Matériau de construction | Acier inoxydable | Plastique ou métal de faible qualité |

| Fourchette | $800 - $5000 | $10 - $100 |

| Applications | Industriel, usines alimentaires | Cuisines à domicile, restaurants |

| Niveau d'automatisation | Entièrement automatique | Manuel ou semi-automatique |

Questions fréquemment posées (FAQ)

Quel est le taux de pelage moyen d'un modèle commercial de machine à éplucher l'ail?

La plupart des machines ont une efficacité de pelage de 95% ou plus, en fonction de la variété d'ail et du type de machine.

Puis-je utiliser une machine à éplucher l'ail pour l'ail humide?

La plupart machines à éplucher l'ail commerciales sont conçus pour l'ail sec. L'ail mouillé peut réduire l'efficacité et obstruer le système de circulation d'air..

Ces machines endommagent-elles l'ail?

Non. Les machines de haute qualité sont construites pour minimiser les meurtrissures ou les bris. Le pelage s'effectue en douceur à l'aide d'air ou d'une friction douce.

Un compresseur d'air est-il inclus avec la machine?

Dans la plupart des cas, machine à éplucher l'ail commerciale les unités n'incluent pas le compresseur d'air, mais les fabricants recommandent généralement des modèles compatibles.

Comment nettoyer une machine à éplucher l'ail?

Démontez simplement les pièces clés et rincez-les à l'eau tiède. Débranchez toujours l’alimentation électrique et l’alimentation en air avant de nettoyer.

Demandes d'offres et réponses pour les acheteurs commerciaux de machines à éplucher l'ail

1. Nous avons besoin d'une machine à éplucher l'ail pour 300 capacité kg/h. Pouvez-vous fournir des spécifications et un devis?

Oui, notre modèle GP-300 prend en charge 300 kg/heure. Pouvoir: 0.3 kW, Pression atmosphérique: 0.75–1,0 MPa, Taux de pelage ≥96 %, Taille: 950×650×1050 mm. Le devis sera basé sur le port de destination et les besoins en matière d'emballage.

2. Votre éplucheur d'ail commercial est-il adapté à une utilisation dans un environnement de salle blanche ??

Oui. Nos machines sont construites avec SUS 304 conceptions en acier inoxydable et scellées adaptées aux salles blanches conformes aux BPF.

3. Quel est le délai de livraison pour 2 unités du modèle GP-1000 au Mexique?

Le temps de production est de 7 à 10 jours. L'expédition par voie maritime vers le Mexique prend 25 à 35 jours. Nous pouvons organiser les conditions CIF ou DDP.

4. Proposez-vous une ligne complète de transformation de l'ail, y compris le fractionnement, peeling, et trancher?

Oui. Nous fournissons des solutions clé en main avec disjoncteur d'ampoule, éplucheur, trancheuse, broyeur de pâte, séchoir, et machine d'emballage.

5. Votre machine à éplucher l'ail peut-elle fonctionner en continu pendant 8+ heures?

Oui. Nos éplucheurs d'ail commerciaux sont de qualité industrielle et peuvent fonctionner pendant plus de 8 heures par quart de travail avec un entretien approprié.

6. Fournissez-vous une assistance à l'installation sur site aux Émirats arabes unis?

Oui. Nous proposons l'envoi de techniciens pour l'installation et la formation aux Émirats arabes unis et dans d'autres pays.. Un support vidéo est également disponible.

7. Pouvons-nous utiliser votre éplucheur d'ail commercial pour le prétraitement de la production d'ail noir?

Oui. Notre éplucheur enlève la peau en douceur, garder l'ail intact - idéal pour la fermentation.

8. Quelles certifications détiennent vos machines? (CE, ISO, etc.)

Nous fournissons du CE, ISO 9001:2015, et certifications UL/CSA en option. Déclarations sur les matériaux de qualité FDA disponibles.

9. Est-il possible d'intégrer cette machine à un système de lavage de l'ail?

Oui. Nous pouvons fournir des systèmes d'automatisation intégrés, y compris des laveurs d'ail, convoyeurs, et séchoirs.

10. Nous avons besoin d'une machine à éplucher l'ail pouvant fonctionner avec une pression d'air variable. Personnalisez-vous ces modèles?

Oui. Nous proposons des systèmes à pression régulée et des configurations personnalisées pour les installations avec une alimentation en air variable.

Conclusion

Pour les fabricants de produits alimentaires et les installations de transformation, investir dans un machine à éplucher l'ail commerciale l'unité est une décision intelligente et nécessaire. Il offre une grande efficacité, hygiène, et évolutivité – facteurs essentiels pour une production alimentaire compétitive.

Que vous’vous dirigez une grande usine de pâte d’ail ou une cuisine commerciale centralisée, ces machines amélioreront votre ligne de production, réduire le travail, et améliorer la qualité des produits.

Machine à éplucher l'ail commerciale les solutions ne sont pas seulement une mise à niveau : elles’ça change la donne.