1. Qu'est-ce qu'une machine à crêpes?

UN machine à crêpes est un appareil spécialisé de transformation des aliments conçu pour produire des, crêpes cuites uniformément automatiquement ou semi-automatiquement. Contrairement aux poêles ou planchas manuelles, cette machine assure une épaisseur uniforme, texture parfaite, et une température de cuisson constante pour chaque crêpe.

Qu'il soit utilisé dans les cafés, restaurants, hôtels, ou des usines alimentaires à grande échelle, un machine à crêpes simplifie la production et augmente l'efficacité de la production. Avec contrôle précis de la température, surfaces antiadhésives, et distribution automatique de la pâte, il permet aux opérateurs de préparer de délicieuses crêpes avec un minimum d'effort.

2. Crêpière automatique: Entièrement automatisé pour plus d'efficacité

2.1 Qu'est-ce qu'une crêpière automatique?

Un crêpière automatique est une solution moderne pour les entreprises qui nécessitent une production continue et cohérente de crêpes. Il gère la distribution de la pâte, diffusion, pâtisserie, et rouler automatiquement. Ces machines sont parfaites pour cuisines industrielles, usines d'aliments surgelés, et grands services de restauration.

2.2 Comment fonctionne la crêpière automatique

Le processus de travail est simple mais efficace:

- Alimentation en pâte: La pâte est pompée ou versée dans une trémie.

- Distribution: Un système de dosage répartit uniformément la pâte sur la plaque chauffante ou le tambour rotatif.

- Cuisson: La chaleur est répartie uniformément sur toute la surface, s'assurer que les deux côtés sont parfaitement cuits.

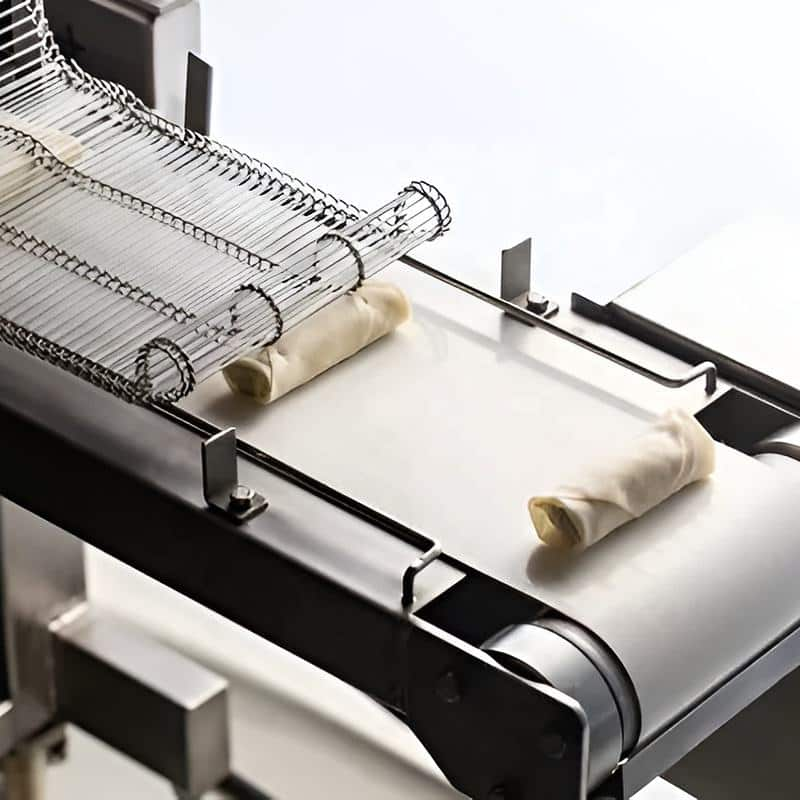

- Roulement ou pliage: Certains modèles plient ou roulent automatiquement les crêpes.

- Sortie et refroidissement: Les crêpes finies sont refroidies et transférées pour être emballées ou servies.

Les crêpières automatiques assurent production à grande vitesse, réduire le travail, et maintenir une qualité constante – idéal pour la production industrielle.

3. Crêpière commerciale: Conçu pour les restaurants et les cafés

3.1 Pourquoi choisir une crêpière commerciale

UN crêpière professionnelle est conçu pour un usage professionnel, alliant durabilité et contrôle précis de la cuisson. Fait de acier inoxydable avec plaques en fonte ou antiadhésives, il fournit des résultats cohérents pendant de longues heures de fonctionnement.

Avantages:

- Température réglable (50°C–300°C)

- Temps de chauffage et de récupération rapides

- Nettoyage et entretien faciles

- Conception compacte pour une utilisation sur un comptoir

3.2 Applications de la crêpière commerciale

Les crêpières commerciales sont largement utilisées dans:

- Restaurants et cafés – préparer des crêpes sucrées et salées pour les clients

- Hôtels et Buffets – pour les stations de petit-déjeuner ou de brunch

- Camions de restauration – modèles portables idéaux pour les vendeurs ambulants

- Représentation des événements – production de crêpes à grande échelle pour des festivals ou des soirées

Qu'il s'agisse de crêpes françaises fourrées au Nutella ou de savoureux wraps au jambon et au fromage, un crêpière professionnelle garantit des résultats parfaits à chaque fois.

4. Ligne de production de crêpes: Fabrication de crêpes à l'échelle industrielle

4.1 Aperçu de la ligne de production de crêpes

UN ligne de production de crêpes est un système intégré conçu pour la production à grande échelle. Il automatise chaque étape – du mélange de la pâte à la cuisson et à l'emballage – et peut produire des milliers de crêpes par heure..

Les composants typiques incluent:

- Mélangeur à pâte et réservoir de stockage

- Pompe d'alimentation et système de dosage

- Tambour de cuisson ou four à convoyeur

- Convoyeur de refroidissement

- Unité d'empilage et de conditionnement

4.2 Spécifications techniques de la ligne de production de crêpes

| Paramètre | Plage de spécifications |

|---|---|

| Capacité | 1000–8000 PC / Hour |

| Type de chauffage | Électrique / Gaz |

| Diamètre de la crêpe | 100–400mm |

| Épaisseur | 0.5–2,5mm |

| Pouvoir | 10–50 kW |

| Système de contrôle | Écran tactile PLC |

| Matériel | Acier inoxydable de qualité alimentaire |

| Dimensions | Personnalisable |

Un entièrement automatisé ligne de production de crêpes est idéal pour les fabricants de produits alimentaires produisant crêpes surgelées, collations prêtes à manger, ou wraps dessert pour la vente au détail et l'exportation.

5. Machine à crêpes industrielle: Pour la fabrication en grand volume

5.1 Caractéristiques de la machine à crêpes industrielle

Un machine à crêpes industrielle est conçu pour fonctionner sans arrêt, production à grande échelle. Il utilise technologie de cuisson continue, s'assurer que chaque crêpe est cuite uniformément et efficacement.

Caractéristiques principales:

- Cuisson continue à tapis ou à tambour

- Système de dosage automatique de la pâte

- Température et vitesse réglables

- Chauffage économe en énergie

- Structure robuste en acier inoxydable

5.2 Avantages de la machine à crêpes industrielle

- Produit des crêpes cohérentes à grande échelle

- Réduit les coûts de production et la dépendance au travail

- Compatible avec les systèmes d'emballage

- Intégration facile avec d'autres lignes de transformation alimentaire

Les machines à crêpes industrielles sont idéales pour fabriques de crêpes surgelées, fournisseurs de supermarchés, et fabricants de snacks.

6. Crêpière Électrique: Compact et convivial

6.1 Avantages de la crêpière électrique

Le crêpière électrique est l'une des options les plus populaires pour les petites entreprises et les particuliers.. Il fonctionne à l'électricité et offre un contrôle précis de la température pour une cuisson uniforme..

Avantages clés:

- Fonctionnement prêt à l'emploi

- Propre et sûr pour une utilisation en intérieur

- Plaque antiadhésive pour un nettoyage facile

- Thermostat réglable pour une cuisson parfaite

6.2 Idéal pour les petites entreprises

Le crêpière électrique est parfait pour:

- Cafés

- Cafétérias scolaires

- Stands de petit-déjeuner

- Services de restauration

Compact, économe en énergie, et abordable – c’est un excellent point de départ pour les petits entrepreneurs de crêpes.

7. Mini-crêpière: Parfait pour les startups et l’usage domestique

7.1 Qu'est-ce qu'une mini crêpière?

UN mini-crêpière est un petit, machine portable idéale pour la production à faible volume ou pour un usage domestique. C'est compact, facile à utiliser, et convient aux débutants qui souhaitent se lancer dans la vente de crêpes.

7.2 Pourquoi choisir une mini crêpière

- Investissement abordable

- Chauffage et cuisson rapides

- Nettoyage et rangement simples

- Idéal pour tester de nouvelles recettes

Bien qu’il ne soit pas adapté à une production à grande échelle, un mini-crêpière aide les petits vendeurs ou les cafés à proposer des produits frais, des crêpes préparées sur commande efficacement.

8. Paramètres techniques clés de la machine de fabrication de crêpes

Lors du choix d'un machine à crêpes, considérez ces spécifications importantes:

| Paramètre | Gamme / Option |

|---|---|

| Capacité | 50–5000 crêpes/heure |

| Pouvoir | 2–40 kW |

| Méthode de chauffage | Électrique ou Gaz |

| Diamètre de la crêpe | 100–400mm |

| Matériel | Acier inoxydable / Fonte |

| Plage de température | 50–300°C |

| Niveau d'automatisation | Manuel / Semi-automatique / Entièrement automatique |

| Système de contrôle | Mécanique / Numérique / CLu |

| Poids | 20–1000 kg |

Choisir la bonne machine en fonction de ces paramètres garantit la meilleure adéquation à vos besoins de production.

9. Comment choisir la meilleure machine à faire des crêpes

Choisir le parfait machine à crêpes dépend de plusieurs facteurs:

- Capacité de production – Estimez vos besoins quotidiens en production.

- Disponibilité de l'espace – Assurer suffisamment d’espace pour les mouvements de la machine et de l’opérateur.

- Type de chauffage – Gaz pour production en grand volume, électrique pour une utilisation intérieure propre.

- Matériel et qualité de construction – Choisissez l’acier inoxydable pour l’hygiène et la durabilité.

- Niveau d'automatisation – Manuel pour la flexibilité, automatique pour la production à grande échelle.

- Service après-vente – Un support fiable garantit une stabilité à long terme.

10. Conseils d’entretien et de nettoyage des machines à crêpes

Un bon entretien garantit un fonctionnement fluide et une longue durée de vie.

Nettoyage quotidien:

- Essuyer les assiettes avec un chiffon humide après utilisation.

- Évitez les nettoyants abrasifs qui endommagent les revêtements antiadhésifs.

Entretien hebdomadaire:

- Vérifier les vis et les éléments chauffants.

- Lubrifier les pièces mécaniques si nécessaire.

Inspection mensuelle:

- Tester le thermostat et les contrôles de température.

- Inspecter les signes d’usure électrique ou d’accumulation d’huile.

Un bien entretenu machine à crêpes fonctionne mieux, dure plus longtemps, et garantit une qualité de produit constante.

11. Dépannage des problèmes courants

| Problème | Cause possible | Solution |

|---|---|---|

| Cuisine inégale | Déséquilibre de température | Calibrer ou remplacer la plaque chauffante |

| Pâte collante | Revêtement endommagé ou faible chaleur | Ajuster la température ou recouvrir la surface |

| Déchirure de crêpe | Pâte trop fine | Ajuster la recette ou la viscosité |

| La machine ne chauffe pas | Alimentation électrique défectueuse | Vérifier le fusible ou le câblage |

| Bords brûlés | Chaleur excessive ou cuisson excessive | Réglage de température plus bas |

Comprendre ces problèmes courants vous aide à minimiser les temps d'arrêt et à maintenir une production cohérente.

12. Prix de la machine à crêpes et retour sur investissement

12.1 Fourchette

| Taper | Fourchette (USD) |

|---|---|

| Mini-crêpière | $100 - $300 |

| Crêpière Électrique | $300 - $800 |

| Crêpière commerciale | $800 - $3,000 |

| Crêpière automatique | $5,000 - $20,000 |

| Ligne de production de crêpes industrielles | $30,000 - $100,000+ |

12.2 Retour sur investissement (Retour de retour)

Avec la popularité croissante des crêpes dans le monde, investir dans un machine à crêpes offre un retour sur investissement rapide. Les entreprises peuvent récupérer leurs coûts en quelques mois seulement en vendant des crêpes fraîches ou en distribuant des produits emballés aux supermarchés..

13. Pourquoi choisir DT Food Machine comme fournisseur de machines à crêpes

Lors de l'achat d'un machine à crêpes, il est essentiel de s’associer à un fabricant fiable.

Machine alimentaire DT est l'un des principaux fournisseurs de machines alimentaires avec des décennies d'expérience dans les lignes de production de crêpes et de pancakes.

Nos avantages:

- Conception personnalisée pour différentes capacités

- CE & Matériel certifié ISO

- Structure en acier inoxydable de haute qualité

- Des conceptions économes en énergie et conviviales

- Excellent service après-vente mondial

Machines alimentaires DT machines à crêpes industrielles jouissent de la confiance des producteurs alimentaires, restaurants, et distributeurs dans le monde entier.

14. Tendances futures de la technologie des machines à crêpes

Le machine à crêpes l'industrie continue d'évoluer avec les innovations modernes:

- Systèmes API intelligents avec surveillance à distance

- Chauffage infrarouge économe en énergie

- Convoyeurs de cuisson multicouches pour les usines à grande échelle

- Unités de pliage et d'emballage automatiques

- Suivi de la production basé sur l'IoT pour un meilleur contrôle qualité

À mesure que l’automatisation se développe, la prochaine génération de crêpières sera plus rapide, nettoyeur, et plus durable.

15. Machine de fabrication de crêpes

UN machine à crêpes est un investissement puissant pour toute entreprise alimentaire, des petits cafés aux lignes de production industrielles. Cela améliore la cohérence, productivité, et l'hygiène tout en réduisant les coûts de main d'œuvre.

Que vous choisissiez un crêpière automatique pour votre restaurant ou un ligne de production de crêpes pour votre usine, cette machine garantit des crêpes de qualité professionnelle à chaque fournée.

Avec les avancées technologiques, efficacité énergétique, et l'automatisation, les machines à crêpes façonnent l'avenir de l'industrie agroalimentaire mondiale – une crêpe parfaite à la fois.