Peanut butter production has become one of the most attractive opportunities in the global food industry. As consumer demand for healthy, plant-based, and protein-rich foods grows, the market for peanut butter continues to expand across continents. Entrepreneurs and food manufacturers are increasingly asking one key question:

What is the ROI (Kapitalrendite) for peanut butter production?

This detailed guide explores the economics behind peanut butter manufacturing — from setup costs and market demand to operating expenses, profit margins, and expected returns. It is designed for investors, factory owners, and food processors who are considering entering the peanut butter business or upgrading existing production lines.

1. Global Market Overview

Peanut butter is more than a Western household staple; it has become a global commodity with rising popularity in Asien, Afrika, und Lateinamerika. The market has grown steadily over the past decade, with strong momentum in health-conscious and plant-based food segments.

Key statistics (2024–2025 estimates):

- Global market value: Over USD 6.5 billion and rising

- Annual growth rate: Around 5–6%

- Leading regions: Nordamerika, Europa, Asiatisch-pazifik

- Top growth drivers: Health trends, protein snacks, vegan diets

This global growth means one thing for investors: steady demand and strong profitability potential. As long as production is efficient and marketing is smart, the ROI in peanut butter manufacturing can be highly attractive.

2. What ROI Means in Food Manufacturing

ROI (Return on Investment) measures how much profit you can earn relative to your initial investment. It is calculated as: ROI=Net ProfitTotal Investment×100\text{ROI} = \frac{\text{Reingewinn}}{\text{Total Investment}} \times 100ROI=Total InvestmentNet Profit×100

In einfachen Worten, it shows how quickly your investment pays back and how much return you get over time.

For food manufacturing, ROI depends on:

- Initial equipment and plant setup cost

- Raw material prices (mainly peanuts)

- Production efficiency and capacity

- Labor and energy costs

- Product pricing and market demand

For peanut butter, ROI is often higher than average compared with other food processing lines because peanuts are inexpensive, shelf life is long, and consumer demand remains stable all year round.

3. Kapitalinvestition: Setup Cost Breakdown

Starting a peanut butter factory requires careful planning and capital allocation. Let’s break down the approximate costs for a small-to-medium-scale plant with a capacity of 500–1000 kg/Stunde.

| Investment Component | Geschätzte Kosten (USD) | Beschreibung |

|---|---|---|

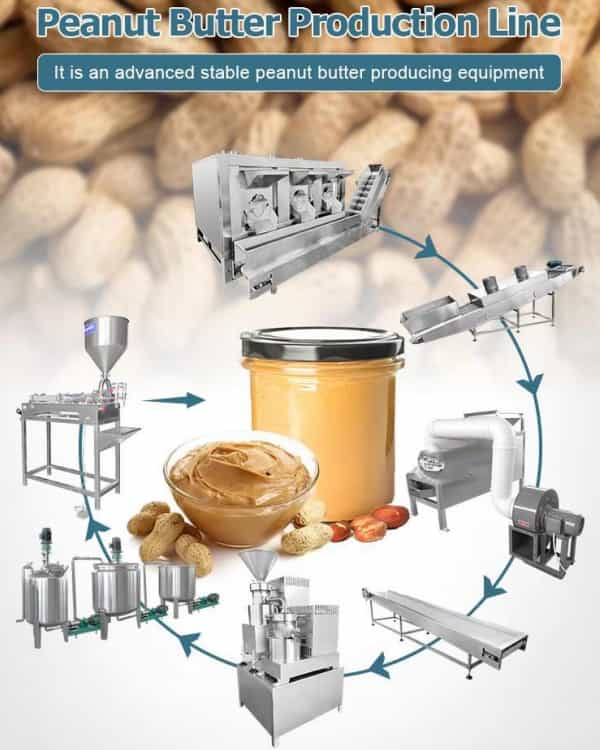

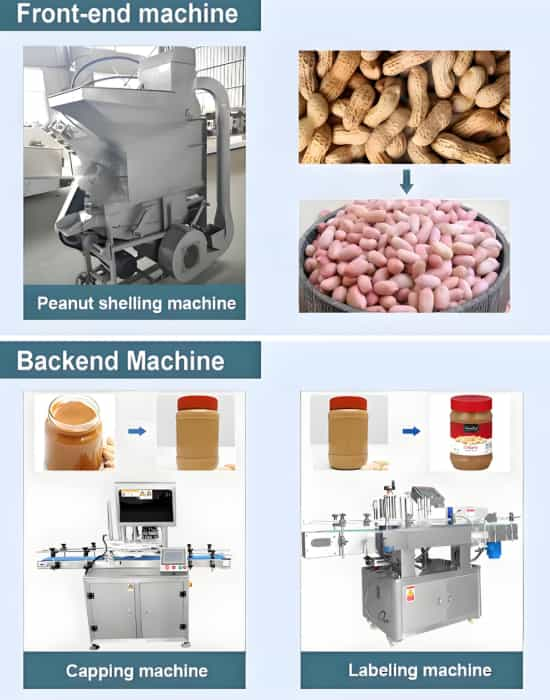

| Erdnussbutterproduktionslinie | $30,000 - - $120,000 | Includes cleaning, roasting, Schleifen, Mischen, and filling machines |

| Gebäude & Versorgungsunternehmen | $20,000 - - $60,000 | Factory space, electrical setup, water system |

| Raw material (Erdnüsse) | $5,000 - - $15,000 (initial stock) | Quality peanuts for first production cycle |

| Verpackungsausrüstung & Materialien | $5,000 - - $20,000 | Jars, Etiketten, sealing machines |

| Arbeit & Ausbildung | $3,000 - - $10,000 | Staff and operator training |

| Lizenzierung & certification | $2,000 - - $5,000 | Food safety, Export, or quality certifications |

| Working capital | $10,000 - - $25,000 | For utilities, marketing, and early operations |

Total estimated initial investment:

Between $70,000 Und $250,000, je nach Produktionsmaßstab, Automatisierungsstufe, and local conditions.

Reliable machinery suppliers such as DT-Lebensmittelmaschine offer scalable production solutions to match these investment ranges, ensuring both entry-level and industrial manufacturers can operate efficiently.

4. Operating Costs and Production Efficiency

Once your factory is operational, ongoing expenses determine your actual profit margins. Typical monthly operating costs enthalten:

| Category | Kostenbereich (USD/month) | Notizen |

|---|---|---|

| Rohe Erdnüsse | $4,000 - - $10,000 | Depends on price per ton and output volume |

| Arbeit | $2,000 - - $5,000 | Hängt von der Automatisierungsstufe ab |

| Strom & fuel | $1,000 - - $3,000 | For roasting, Schleifen, Füllung |

| Verpackungsmaterialien | $1,000 - - $2,500 | Labels, Gläser, caps |

| Wartung & Reinigung | $500 - - $1,000 | Equipment upkeep |

| Marketing & Logistik | $1,000 - - $3,000 | Distribution and promotion |

Total monthly costs typically range from $9,000 Zu $25,000.

Efficient machinery and energy-saving systems play a major role in minimizing these costs, directly improving ROI.

Advanced production lines from DT-Lebensmittelmaschine are designed to reduce power consumption, automate cleaning, and simplify maintenance — all of which help lower recurring expenses.

5. Peanut Butter Selling Price and Profit Margins

Peanut butter has one of the most stable price structures in the food industry. Retail prices depend on region and brand positioning, but wholesale and manufacturing margins remain attractive.

| Produkttyp | Average Selling Price (Wholesale) | Typical Profit Margin |

|---|---|---|

| Standard smooth peanut butter | $2.5 - - $3.5 / kg | 25–35% |

| Chunky peanut butter | $3 - - $4 / kg | 30–40% |

| Natural/organic peanut butter | $4 - - $6 / kg | 40–50 % |

| Flavored or honey peanut butter | $4.5 - - $7 / kg | 45–55% |

Profit margins depend heavily on raw peanut prices Und Produktionseffizienz. Bulk purchasing peanuts and maintaining minimal waste during processing can boost margins significantly. High-end or organic peanut butter products offer even better returns, particularly in export markets.

6. Example ROI Calculation

Let’s calculate ROI for a mid-sized peanut butter factory producing 1,000 kg per day (25,000 kg per month).

Key assumptions:

- Verkaufspreis: $3.50/kg

- Production cost (all inclusive): $2.50/kg

- Monthly sales: 25,000 kg × $3.50 = $87,500

- Monthly production cost: 25,000 kg × $2.50 = $62,500

- Monthly net profit: $25,000

If your total initial investment is $200,000, your annual profit is roughly $300,000 ($25,000 × 12). ROI=300,000200,000×100=150%\text{ROI} = \frac{300,000}{200,000} \times 100 = 150\%ROI=200,000300,000×100=150%

This means the business can potentially recover its investment in less than one year under optimal conditions. Even after adjusting for downtime or market fluctuations, ROI remains highly favorable compared with many other food industries.

7. Factors That Affect ROI

The profitability and ROI of a peanut butter plant depend on several key factors:

7.1 Raw Material Price Fluctuation

Peanut prices can vary depending on harvest seasons and global supply. Using local sourcing or contracting directly with farmers can help stabilize costs.

7.2 Produktionseffizienz

High-performance equipment ensures lower waste, faster processing, and less downtime. Automation minimizes labor costs and human error.

7.3 Product Diversification

Offering multiple flavors or packaging sizes expands your target market. Zum Beispiel, mini snack packs and natural peanut butter lines attract different consumer groups.

7.4 Branding and Distribution

Strong marketing, eye-catching packaging, and reliable distribution channels are essential for maximizing market reach and maintaining profit stability.

7.5 Energy Management

Energy-efficient roasters and grinders can reduce electricity costs by up to 20%, directly improving profit margins.

Modern systems from DT-Lebensmittelmaschine include energy-saving heating technology and smart temperature control, helping producers achieve optimal roasting with minimal waste.

8. Market Opportunities and Trends

Peanut butter consumption is no longer limited to traditional markets like the United States. Emerging economies are adopting it rapidly due to increasing health awareness and Western food influence.

Emerging markets include:

- Asiatisch-pazifik: Rapidly growing middle-class population

- Afrika: Rising urbanization and affordable protein demand

- Südamerika: Expanding packaged food sector

- Naher Osten: Health-conscious youth population

These regions offer excellent ROI potential because demand often exceeds local supply, allowing higher profit margins for imported or locally produced peanut butter.

9. Product Line Expansion Ideas

After establishing your main peanut butter brand, you can diversify to increase profitability:

- Peanut paste for bakeries and sauces

- Peanut-based protein snacks

- Peanut oil extraction

- Flavored peanut spreads (Schokolade, Honig, Zimt)

- Peanut butter sachets and single-serve packs

These products use the same base ingredient and machinery, maximizing your asset utilization and improving ROI over time.

10. Risk Management and ROI Stability

Every investment carries risks. Understanding and managing them keeps your ROI steady.

Common risks include:

- Raw material shortages – Secure long-term supply contracts.

- Price competition – Differentiate through branding and quality.

- Equipment downtime – Schedule preventive maintenance.

- Regulatory hurdles – Obtain necessary food safety certifications early.

- Changing consumer trends – Adapt quickly with new product variations.

Manufacturers who partner with trusted equipment suppliers like DT-Lebensmittelmaschine often gain long-term support, Ersatzteile Verfügbarkeit, and training programs, reducing operational risk and ensuring continuous productivity.

11. Long-Term ROI: The Power of Scaling Up

The peanut butter business scales efficiently. Once the initial production line is set up, expanding capacity requires relatively little additional investment compared with startup costs.

Zum Beispiel:

- Doubling output may increase cost by only 40–50 %, not 100%.

- Energy and labor costs remain nearly constant due to automation.

- Packaging in bulk for B2B clients lowers per-unit expenses.

This scalability makes peanut butter manufacturing a high-ROI long-term investment, especially for entrepreneurs targeting export or private-label production.

12. ROI Comparison: Peanut Butter vs. Other Food Products

| Produkttyp | Average ROI | Rückzahlungsperiode | Notizen |

|---|---|---|---|

| Erdnussbutter | 80–150% | 8–14 months | High global demand, Lange Haltbarkeit |

| Tomatenpaste | 40–70 % | 12–18 months | Seasonal demand |

| Fruit jam | 50–90% | 10–16 months | Higher sugar cost |

| Fried snacks | 60–110% | 9–12 Monate | Faster turnover but higher oil usage |

Peanut butter consistently delivers one of the highest ROI levels among processed food categories because it balances long shelf life, steady ingredient supply, and strong consumer loyalty.

13. Sustainability and Long-Term Value

Sustainability adds another dimension to ROI. By using energy-efficient equipment, recyclable packaging, and ethically sourced peanuts, you not only enhance brand reputation but also attract environmentally conscious consumers.

Sustainable practices may also qualify your business for government incentives, grants, or export benefits — all of which improve long-term profitability.

14. How to Maximize ROI in Peanut Butter Production

Here are actionable strategies to boost your return on investment:

- Choose the right equipment size – Avoid under- or over-investing.

- Source quality peanuts locally – Reduce transportation and storage costs.

- Adopt automation – Cut labor costs and increase consistency.

- Focus on energy management – Invest in efficient roasters and grinders.

- Diversify your products – Offer smooth, knackig, and flavored variants.

- Develop a strong brand – Attractive packaging and clear labeling build loyalty.

- Control waste – Every gram saved increases profitability.

- Expand distribution – Sell to retail chains, Bäckereien, and online stores.

- Monitor performance metrics – Track cost per kg and energy usage.

- Reinvest profits – Scale production to reach new markets.

Partnering with a professional equipment manufacturer such as DT-Lebensmittelmaschine helps ensure technical reliability, production consistency, and faster ROI realization through customized solutions.

15. Abschluss: Is Peanut Butter Production a Good Investment?

Peanut butter manufacturing Angebote exceptional ROI potential due to its simple production process, low raw material costs, and strong, year-round market demand.

With smart investment planning, effiziente Maschinen, and strong market positioning, most producers can recover their initial costs within 8 Zu 14 Monate. The long shelf life, global demand, and scalability make it one of the most profitable sectors in food processing Heute.

For investors and entrepreneurs seeking a sustainable and rewarding opportunity, peanut butter production stands out as a top-tier business model — combining consistent returns, global growth, and long-term consumer appeal.