Einführung

Tomato paste is a globally consumed product used as a base ingredient in countless culinary applications. From pasta sauces to soups and ready-to-eat meals, the demand for tomato paste continues to grow across markets worldwide. Infolge, the need for efficient, automatisiert Tomato Paste Machines Production Lines is more critical than ever. In diesem umfassenden Leitfaden, we explore the essential machinery, Produktionsprozess, and technological innovations behind tomato paste manufacturing, brought to you by DT-Lebensmittelmaschine — a leading provider of food processing equipment.

1. Understanding Tomato Paste Machines Production Lines

Tomato paste production involves several critical stages that transform fresh tomatoes into a concentrated, shelf-stable product. The process must maintain flavor, Farbe, and nutritional value while ensuring hygiene and operational efficiency.

Key Objectives of Tomato Paste Production:

- High yield extraction from fresh tomatoes

- Removal of skin and seeds

- Concentration to specific brix levels (Z.B., 28-30% oder 36-38%)

- Pasteurization and aseptic packaging

Categories of Tomato Paste:

- Hot Break Tomato Paste: Made by heating crushed tomatoes quickly to preserve pectin.

- Cold Break Tomato Paste: Crushed tomatoes are kept at a lower temperature, ideal for ketchup or sauces.

- Intermediate Break: A blend of both processes to balance viscosity and color.

2. Key Machines in a Tomato Paste Machines Production Lines

DT Food Machine designs and manufactures a complete range of tomato paste processing equipment. Below is a breakdown of the key machinery involved:

2.1 Fresh Tomato Receiving and Washing Machine

- Funktion: Removes soil, Trümmer, and impurities from fresh tomatoes.

- Merkmale: Bubble washer or rotary drum washer; Edelstahlkonstruktion.

- Optionen: Air blowing washer with ozone sterilization.

2.2 Sortierförderer

- Funktion: Manual or optical sorting of damaged or rotten tomatoes.

- Vorteile: Ensures only quality tomatoes proceed to processing.

- Automatisierung: Optional AI-based visual sorting systems.

2.3 Crushing and Preheating Machine

- Funktion: Breaks tomatoes and heats them to deactivate enzymes.

- Design: Enzyme-inactivating tube heater; adjustable temperature control.

- Integration: Available as part of combined crushing-preheating module.

2.4 Pulper und Finisher

- Funktion: Separates seeds and skins from pulp.

- Ausgabe: Smooth tomato juice or pulp ready for concentration.

- Materialien: All contact parts made with food-grade stainless steel.

2.5 Verdampfer (Vacuum Concentration System)

- Funktion: Reduces water content to desired brix.

- Typ: Forced circulation evaporators; vacuum operation to protect color/flavor.

- Kapazität: Bis zu 50 tons per hour depending on configuration.

2.6 Sterilisator

- Funktion: Thermal treatment to ensure microbial safety.

- Typen: Tube-in-tube or plate-type sterilizers.

- Automatisierung: PLC-controlled with real-time monitoring.

2.7 Aseptische Abfüllmaschine

- Funktion: Packs sterilized paste into aseptic bags or drums.

- Merkmale: Stickstoffspülung, CIP/SIP systems, SPS -Automatisierung.

- Kapazität: Single and double-head filling options.

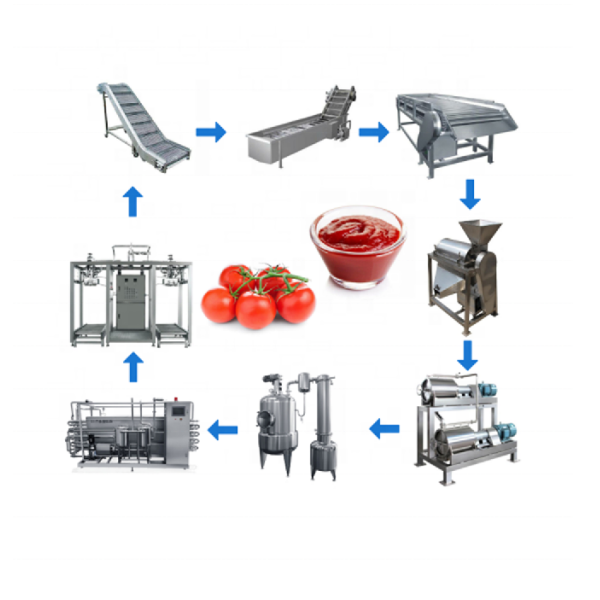

3. Complete Process Flow: Tomato to Paste

- Tomato receiving and unloading

- Washing and sorting

- Crushing and preheating

- Pulping and filtration

- Evaporation/concentration

- Sterilisation

- Aseptic filling and storage

Each stage in the production line can be customized depending on tomato variety, final product requirements, and packaging type. DT Food Machine offers engineering consultation to tailor each process precisely.

4. Tomato Paste Packaging Options

- Aseptic Drums: 220L for industrial buyers

- Sachets or Stand-up Pouches: 70g to 500g for retail

- Glass Bottles or Metal Cans: Popular for local markets

- Bag-in-Box Systems: For foodservice operations

All DT Food Machine lines can be customized to include various packaging solutions using servo-driven filling systems, intelligent capping machines, and automatic labeling units.

5. Technical Specifications to Consider Tomato Paste Machines Production Lines

When planning your tomato paste line, halten:

- Input capacity: Aus 1 TPH to 50+ TPH

- Final brix requirement

- Energy source (steam/electric)

- Automatisierungsstufe (Handbuch, halbautomatisch, full auto)

- Packaging form

- Water and electricity consumption

- Space and layout constraints

DT Food Machine provides site-specific utility calculations and mechanical layout plans.

6. Advantages of DT Food Machine Equipment

- Robust stainless steel construction

- European standard components (Siemens, Schneider)

- High yield extraction technologies

- Easy-to-clean designs (CIP integrated)

- Energy-efficient evaporators

- Global after-sales service and spare parts

- Compliance with CE, ISO, FDA, and HACCP standards

- Technical training, remote support, and on-site installation

7. Customization and Turnkey Solutions

DT Food Machine offers fully customizable turnkey solutions:

- Factory layout planning

- Utility consumption design

- Equipment manufacturing and installation

- Training and after-sales service

Our engineers conduct feasibility studies, ROI calculations, and integrate ERP-ready control systems to support smart factory solutions.

8. Tomato Paste Machines Production Lines in Different Climates and Regions

- Afrika: Growing need for agro-industrial infrastructure.

- Asien: Increasing consumption due to urbanization.

- Europa: Focus on organic and high-quality paste.

- Südamerika: Expanding food exports require industrial-grade solutions.

DT Food Machine adapts equipment to local power standards, climate considerations, and raw tomato characteristics.

9. Tomato Varieties and Raw Material Considerations

- Roma-Tomaten: High pulp yield

- Heinz 1370: Preferred for commercial paste

- Pear Tomatoes: Excellent color and flavor

DT Food Machine provides insights on matching processing technology with specific cultivars for optimal results.

10. Market Trends and Global Demand Tomato Paste Machines Production Lines

- Increased demand from fast food and processed meal sectors

- Growing export opportunities in Africa, Asien, und Lateinamerika

- Organic and clean-label tomato paste trending

- Rise of centralized tomato paste processing hubs

- Digital traceability and food safety monitoring becoming standard

Modern tomato paste lines must be efficient, flexible, and scalable to meet these evolving trends. DT Food Machine helps you stay competitive.

11. Sustainability and Energy Efficiency

DT Food Machine prioritizes green technology:

- Heat recovery systems in evaporators

- Water-saving CIP systems

- Modular design for space and energy optimization

- Use of solar-assisted preheating (optional)

12. Wartung, Ersatzteile, and Support

- Vorbeugende Wartungspläne

- Ferndiagnose

- Local agent networks in over 30 Länder

- Spare parts available within 72 Std.

- Lifetime technical documentation

13. Training and Installation

- On-site operator training (in English/Spanish/French/Arabic)

- Video tutorials and user manuals

- 3D simulation of production line during planning phase

14. FAQ-Bereich (Extended) Tomato Paste Machines Production Lines

Q4: What certifications does the equipment have?

A: Ce, ISO 9001, SGS, and optionally UL/FDA compliant for certain markets.

Q5: What are the payment terms?

A: Typischerweise 30% deposit, 70% before shipment. Negotiable for long-term clients.

Q6: Can DT Food Machine help with tomato paste recipes?

A: Ja. Our food technologists provide formulations for standard and custom blends.

Q7: Do you offer used/refurbished equipment?

A: Occasionally. Inquire about current availability.

15. Case Studies and Success Stories

Fall 1: Nigeria (2023)

A 20TPH tomato paste plant designed, installed, and commissioned in under 120 Tage. Local staff trained. ROI in 18 Monate.

Fall 2: Peru (2022)

Custom line for dual tomato paste and mango puree. Operates with solar-powered preheating unit.

Fall 3: Saudi-Arabien (2024)

Fully automated line with ERP integration, serving GCC market with aseptic and retail SKUs.

Conclusion Tomato Paste Machines Production Lines

Tomato paste production is a high-demand, profitable sector requiring the right technology and partners. With DT Food Machine’s advanced engineering, reliable machinery, and expert support, you can confidently build a successful tomato paste production facility anywhere in the world.

DT Food Machine stands at the forefront of food machinery innovation — delivering not just machines, but complete solutions to turn fresh tomatoes into premium-quality paste with maximum efficiency, Sicherheit, and return on investment.