Kartoffelchips gehören weltweit zu den beliebtesten Snacks. Von Supermärkten und Restaurants bis hin zu Straßenverkäufern, Die Nachfrage nach knusprigen Kartoffelchips wächst ständig. Für Unternehmen, die den Einstieg in diesen Markt planen, das Recht wählen Kartoffelchips-Maschine ist der erste und wichtigste Schritt. Einer der Schlüsselfaktoren bei dieser Investitionsentscheidung ist die Preis der Kartoffelchipsmaschine. In diesem Artikel, Wir werden die Preisspanne von Kartoffelchips-Maschinen mit Kapazitäten dazwischen erkunden 100kg und 1000 kg pro Stunde, Analysieren Sie, was sich auf die Kosten auswirkt, und erklären, wie Sie die richtige Ausrüstung für Ihre Produktionsanforderungen auswählen.

1. Einführung in Kartoffelchips-Maschinen

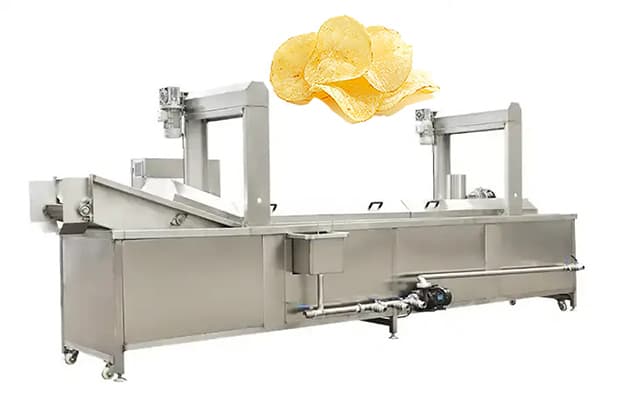

A Kartoffelchips-Maschine ist ein Lebensmittelverarbeitungssystem zum Waschen, schälen, Scheibe, braten, Jahreszeit, und Kartoffeln in knusprige Chips verpacken. Abhängig vom Produktionsmaßstab, Maschinen können kleine halbautomatische Einheiten oder große vollautomatische Produktionslinien sein.

Für kleine Unternehmen, A 100kg/h Kartoffelchipsmaschine kann ausreichend sein. Aber für mittlere oder große Fabriken, Kapazitäten von 300kg/h, 500kg/h, oder sogar 1000kg/h sind besser geeignet. Jede Produktionskapazitätsstufe ist mit unterschiedlichen Kosten verbunden, Spezifikationen, und Anforderungen.

2. Warum der Preis einer Kartoffelchipsmaschine wichtig ist

Bei der Gründung oder Modernisierung eines Kartoffelchips-Unternehmens, Der Maschinenpreis ist nicht nur eine Zahl. Es repräsentiert:

- Kapitalinvestition: Das nötige Vorabgeld, um mit der Produktion zu beginnen.

- Produktionsfähigkeit: Ein höherer Preis spiegelt oft eine größere Kapazität und eine fortgeschrittene Automatisierung wider.

- Langfristige Effizienz: Gut konzipierte Maschinen verbrauchen weniger Energie und reduzieren Abfall.

- Produktqualität: Bessere Maschinen sorgen für gleichbleibenden Geschmack, Textur, und Aussehen.

Daher, Um das Budget auszugleichen, ist es wichtig, den Preis der Kartoffelchips-Maschine zu verstehen, Effizienz, und Produktqualität.

3. Kapazitätsbereich der Kartoffelchips-Maschine: 100kg-1000kg

Hier finden Sie einen Überblick über typische Maschinenkapazitäten und was diese für Ihr Unternehmen bedeuten:

| Maschinenkapazität | Geeignet für | Typische Benutzer | Preisklasse (USD) |

|---|---|---|---|

| 100kg/h | Kleine Geschäfte, lokale Restaurants, Startups | Lokale Snack-Produzenten, neue Unternehmer | $5,000 - - $15,000 |

| 200-300kg/h | Mittlere Produktion | Regionale Distributoren, wachsende Unternehmen | $15,000 - - $35,000 |

| 500kg/h | Mittelgroße Fabriken | Snackmarken, Vertragshersteller | $35,000 - - $60,000 |

| 1000kg/h | Große Industrieanlagen | Internationale Marken, Großserienlieferanten | $60,000 - - $120,000 |

Notiz: Die Preise variieren je nach Maschinenausführung (halbautomatisch vs. vollautomatisch), Material (Edelstahlqualität), Energieeffizienz, und Anpassung.

4. Schlüsselfaktoren, die den Preis von Kartoffelchipsmaschinen beeinflussen

4.1. Automatisierungsstufe

- Halbautomatische Maschinen: Geringere Kosten, erfordern jedoch Handarbeit.

- Vollautomatische Maschinen: Höhere Investitionen, aber geringere Arbeitskosten und Sicherstellung einer kontinuierlichen Produktion.

4.2. Maschinenmaterial

- Hochwertig Edelstahl 304/316 sorgt für Lebensmittelsicherheit und längere Haltbarkeit.

- Billigere Materialien senken die Kosten, können jedoch zu Hygiene- oder Korrosionsproblemen führen.

4.3. Produktionskapazität

- Eine 100-kg/h-Maschine ist kompakt und erschwinglich.

- Ein 1000-kg/h-System erfordert eine größere Ausrüstung, erweiterte Steuerung, und höhere Energieversorgung, dadurch erhöht sich der Preis.

4.4. Technologie & Merkmale

- Automatische Frittiersysteme mit Ölfiltration.

- Kontinuierliche Wasch- und Schälmaschinen.

- Digitale Temperaturregelung.

- Integrierte Gewürz- und Verpackungslinien.

Je fortgeschrittener die Funktionen sind, desto höher der Preis.

4.5. Energiequelle

- Maschinen können mit Strom versorgt werden Strom, Gas, oder Diesel.

- Gasbefeuerte Systeme sind hinsichtlich der Betriebskosten oft günstiger, aber der anfängliche Preis kann höher sein.

5. Kostenaufschlüsselung einer Produktionslinie für Kartoffelchips

Bei der Berechnung des Preises für eine Kartoffelchipsmaschine, Es ist hilfreich, die Kostenverteilung innerhalb einer Produktionslinie zu verstehen:

- Waschen & Schäleinheit - - 10-15% der Gesamtkosten.

- Schneidemaschine - - 5-10%.

- Blanchiermaschine - - 10-15%.

- Entwässerung & Trocknungseinheit - - 5-10%.

- Frittiermaschine - - 25-35% (teuerste Teil).

- Oilieren & Kühlsystem - - 5-10%.

- Gewürzmaschine - - 5-10%.

- Verpackungsmaschine - - 15-20%.

6. Preisvergleich für Kartoffelchips-Maschinen: 100kg vs. 1000kg

100kg/h-System

- Preis: $5,000 - - $15,000

- Am besten für kleine Unternehmen oder Pilotprojekte.

- Erfordert mehr Handarbeit.

500kg/h-System

- Preis: $35,000 - - $60,000

- Ausgewogene Lösung für mittelständische Unternehmen.

- Gute Effizienz bei moderaten Investitionen.

1000kg/h-System

- Preis: $60,000 - - $120,000

- Designed for large-scale, 24/7 Operationen.

- Fully automated, with oil filtration and advanced controls.

7. Zu berücksichtigende Zusatzkosten

Besides the machine price, businesses should plan for:

- Installation & Ausbildung: $2,000 - - $10,000 depending on complexity.

- Versand & Customs: Varies by country.

- Ersatzteile & Wartung: Annual budget of 5-10% of machine cost.

- Energieverbrauch: Electricity or gas bills.

- Fabrik -Setup: Wasserversorgung, oil storage, ventilation, and workspace design.

8. ROI (Return on Investment) of Potato Chips Machines

A potato chips business can be highly profitable. Betrachten wir ein Beispiel:

- Raw Potato Cost: $0.30/kg

- Selling Price of Chips: $3.00/kg

- Yield: 1kg potato = 0.35kg chips

- Gewinnspanne: Around $0.70 - - $1.20 per kg of potato used

With a 500kg/h machine, a factory can process 4,000kg per day (8 Std.). That equals 1,400kg of chips daily, with potential profits exceeding $1,000 per day. This means the machine investment can be recovered within 6-12 Monate.

9. So wählen Sie die richtige Kartoffelchips -Maschine

When evaluating Preis der Kartoffelchipsmaschine, do not just look at numbers. In Betracht ziehen:

- Your Production Scale: Start small or go large depending on market size.

- Automatisierungsanforderungen: Reduce labor cost with full automation if budget allows.

- Qualitätsstandards: Wählen Sie Edelstahl in Lebensmittelqualität für Hygiene und Exportkonformität.

- Ruf des Lieferanten: Arbeiten Sie mit zuverlässigen Herstellern zusammen, die die Installation anbieten, Ausbildung, und After-Sales-Service.

- Anpassung: Einige Anbieter bieten maßgeschneiderte Lösungen zum Würzen von Aromen an, Verpackungsdesign, und Energiequellen.

10. Zukünftige Trends bei Kartoffelchips-Maschinen

- Energieeffizienz: Maschinen mit geringerem Öl- und Stromverbrauch.

- Digitale Überwachung: IoT-fähige Maschinen zur Produktionsverfolgung in Echtzeit.

- Gesündere Chips: Ölarme Brat- und Backchips-Technologie.

- Kompakte Designs: Platzsparende Modelle für urbane Lebensmittelfabriken.

Diese Innovationen können den Preis für Kartoffelchips-Maschinen leicht erhöhen, werden aber langfristige Einsparungen und eine höhere Verbrauchernachfrage mit sich bringen.

11. Warum wählen Sie DT Food Machine

Wenn Sie planen, in ein zu investieren Kartoffelchips-Maschine (100kg-1000kg Kapazität), Der Preis ist ein wichtiger Faktor – aber die Zuverlässigkeit, Haltbarkeit, und Service sind ebenso wichtig.

Bei DT-Lebensmittelmaschine, Wir sind auf die Entwicklung und Lieferung hochwertiger Produkte spezialisiert Kartoffelchips-Maschinen für Unternehmen jeder Größe. Unsere Maschinen bestehen aus lebensmittelechtem Edelstahl, Ausgestattet mit fortschrittlicher Automatisierung, und auf langfristige Leistung ausgelegt.

Ob Sie ein benötigen 100kg/h machine für ein Startup oder ein 1000kg/h vollautomatische Linie für die Großserienproduktion, DT-Lebensmittelmaschine bietet die richtige Lösung zu wettbewerbsfähigen Preisen, Installationsunterstützung, und exzellenter After-Sales-Service.

👉 DT Food Machine – Ihr professioneller Lieferant von Kartoffelchips-Maschinen