Wie Eistüten in der Fabrik hergestellt werden?

DT Food Machine produziert halbautomatische Eiswaffelmaschinen, Ausgabe 300 bis 1200 Stück pro Stunde. Ideale kommerzielle Wahl als Ersatz für traditionelle Handarbeit , Eisdielen, und Eisfabrik.

Kegelverarbeitung im Werk | Maschine zur Herstellung von Waffeltüten

Die Verarbeitung von Tüten in der Fabrik umfasst die Vorbereitung des Rohmaterials, Herstellung von Waffeltüten, Verpackung und Lagerung, Versand und Logistik.

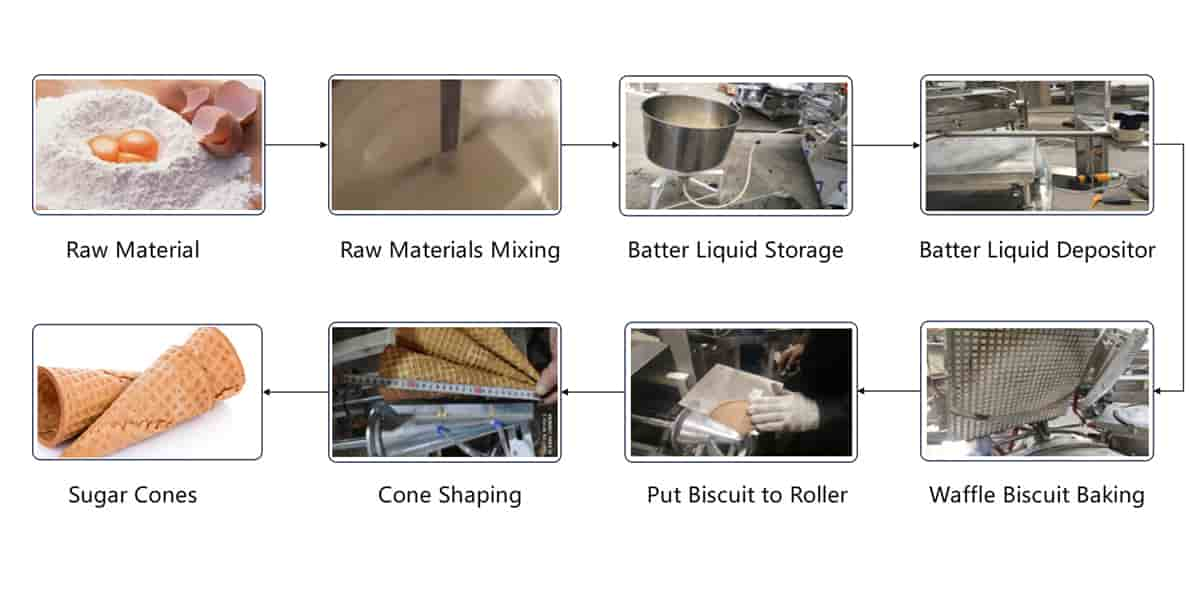

Produktionsablauf zur Herstellung von Waffel- und Zuckertüten | Waffeleisen

Um knusprige Waffeln zuzubereiten, Die Waffeleisen basiert auf dem Herstellungsverfahren für Waffelhörnchen.

Rohstoffe: Weizenmehl, Zucker, Wasser usw. Vorbereitung

Mischen Sie alle Rohstoffe gut in einem guten Verhältnis, was für die Qualität eines Waffelbiskuits unerlässlich ist

Bewahren Sie die gut gemischte Teigflüssigkeit im Vorratsbehälter auf und füllen Sie die eingestellte Teigmenge zum Backen ein.

Der Backprozess erfordert eine genaue Temperaturkontrolle und -einstellung, um gleichmäßige Tüten mit leuchtenden Farben herzustellen.

Nachdem der Waffelkeks gut gebacken ist, schnell zu Waffelhörnchen rollen, wenn der Waffelbiskuit noch weich ist.

Messen Sie die Waffeltüten ab, um sicherzustellen, dass die Größe Ihren Anforderungen entspricht, und dann in Kartons verpacken.

Waffeltüten gegen Zuckertüte | Kommerzieller Waffeleisenautomat

Trotz des Rezepts und der Qualität von Waffelhörnchen und Zuckerhörnchen, wie man sie auf einem handelsüblichen Waffeleisen macht?

Was das Aussehen betrifft, Zuckertüten sind knusprige Eistüten mit flachem Rand, Waffeltüten hingegen sind Eistüten mit natürlicher Krempe. daher, Der Waffelkeks vor dem Ausrollen ist anders. Das heißt, Waffelkekse für Zuckertüten haben die Form eines Fächers, während runder Waffelbiskuit für Waffeltüten.

Aufgrund dieses Unterschieds, Die Backplatten des Waffelhörnchenherstellers für diese Waffeltypen müssen jeweils individuell angepasst werden.

Waffeleisen-Eismaschine Gestalten Sie die Backplatte so, dass runde Waffelkekse entstehen.

Während die Maschine zur Herstellung von Zuckertüten die Backplatten mit konkaven und konvexen Krümmungen gestaltet, um den Waffelkeks in Fächerform zu erzeugen.

So wählen Sie den besten Waffeleisenautomaten aus?

Zucker Kegelhersteller ist eine vielseitige und effiziente Maschine zur Herstellung von Eistüten, Entwickelt, um knusprig zu machen, goldbraune Zuckertüten. Und es können auch Waffelschalen hergestellt werden, Waffelröllchen, Waffeltüten usw.

Je nach Modell, Die halbautomatischen Waffelhörnchen können mit Strom oder Gas betrieben werden, Catering für kommerzielle Nutzung.

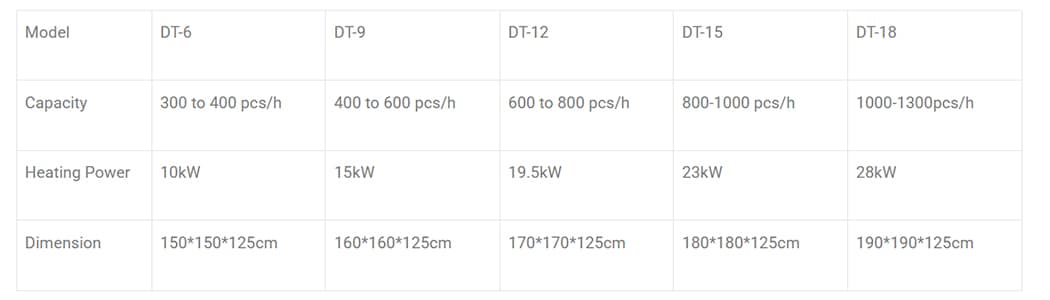

Spezifikation der Eistütenmaschine

Modell: Halbautomatische Waffelkegelmaschine

Kapazität:100 bis 1200 Stück/h

Preis: Bester Preis, direkte Angebot von Fabrik mit höchster Qualität

Heizquelle:Elektrisches Heizung /Gas ( LNG oder LPG )

Maschinenmaterial: Für kommerzielle Waffelkegelmacher, Der Stützrahmen und der Maschinenschutzschild sind aus Edelstahl bestehen 201 Standard. Es dient zur Lebensmittelsicherheit und den einfachen sauberen Zwecken.

Merkmale der Maschine zur Herstellung von Zuckertüten

- Konsistenz und Qualität

Der Zuckertütenhersteller sorgt für eine gleichmäßige Erwärmung beim Backen von Waffeln, was für die goldbraune Farbe sorgt, konsistente Textur und Geschmack. Dies ist insbesondere für Unternehmen von Vorteil, die auf Stammkunden angewiesen sind und ein hohes Qualitätsniveau aufrechterhalten müssen.

- Effizienz

Bei der Maschine zur Herstellung von Waffeltüten muss ein Arbeiter innerhalb von 2 Sekunden Waffelkekse entgegennehmen und auf die Ausrollmaschine legen. Es reduziert viel Arbeitsaufwand und sorgt für eine höhere Leistung.

- Vielseitigkeit

Neben Zuckertüten, Waffeltüten- und Schüsselmaschine können auch zur Herstellung von Waffeltüten verwendet werden, Zuckerkegel, Waffelschalen, Waffelkekse usw., die Vielseitigkeit bieten und Ihr Produktangebot erweitern.

- Anpassbarkeit

Kommerzielle Waffelhersteller können das Logo auf Waffeltüten realisieren, indem sie die Backformen individuell anpassen. Dies soll den Kunden helfen, mit ihrer eigenen Marke Einfluss auf den Markt zu nehmen.

Außerdem, um mehr als ein Zuckerhörnchen in einer Maschine herzustellen, Der Kunde erhält möglicherweise zusätzliche Walzmaschinen oder kann nur zusätzliche Walzersatzteile zum Austausch erhalten, wenn er zwischen Kegelgrößen wechseln muss.

So verwenden Sie die Eistütenmaschine?

Unser Zuckerwaffeleisen ist einfach und effizient zu bedienen. Besonders geeignet für die Bedienung durch Arbeiter ohne Ingenieurhintergrund.

Hersteller von Eiswaffelmaschinen

DT-Lebensmittelmaschine ist ein professioneller Hersteller, der sich auf die Entwicklung und Produktion fortschrittlicher Eistütenmaschinen für globale Lebensmittelunternehmen spezialisiert hat. Mit mehr als einem Jahrzehnt Erfahrung, Das Unternehmen liefert zuverlässig, Hocheffiziente Geräte, die den Anforderungen sowohl kleiner Werkstätten als auch großer Fabriken gerecht werden. DT Food Machine bietet eine umfassende Palette an Lösungen, einschließlich vollautomatische Zuckertütenmaschinen und langlebige Waffeleisen, Entwickelt, um eine gleichmäßige Form zu gewährleisten, knusprige Textur, und stabile Produktionsleistung.

Angetrieben durch Innovation und strenge Qualitätskontrolle, DT Food Machine integriert Präzisionstechnik, Materialien in Lebensmittelqualität, und energieeffiziente Technik in jedes Modell. Das Engagement des Unternehmens für die Kundenzufriedenheit umfasst auch maßgeschneiderte Ausstattungsoptionen, Installation vor Ort, und lebenslanger technischer Support. Egal, ob Sie die Produktion steigern oder eine neue Eiswaffellinie starten, DT Food Machine bietet zuverlässige Ausrüstung und professionellen Service, um Ihr Unternehmen beim Wachstum zu unterstützen.