Einführung

Die globale Eiscremeindustrie wächst weiterhin stetig, Dies treibt die starke Nachfrage nach hochwertigen Eistüten voran. Das Herzstück der Zapfenproduktion ist die Eistüten-Keksmaschine, ein spezielles Lebensmittelverarbeitungsgerät zur Herstellung von Waffeltüten, Zuckerkegel, und flache, kegelförmige Kekse mit einheitlicher Form, schmecken, und Textur.

Für Hersteller, Investoren, und Lebensmittelunternehmer, das Recht wählen Eistüten-Keksmaschine ist entscheidend für die Sicherstellung der Produktqualität, Produktionseffizienz, und langfristige Rentabilität. Dieser Artikel bietet einen umfassenden Überblick über die Funktionsweise dieser Maschinen, ihre Hauptbestandteile, Produktionsprozesse, Technische Spezifikationen, Marktanwendungen, und Investitionsvorteile.

Was ist eine Maschine zur Herstellung von Eiskeksen??

Ein Eistüten-Keksmaschine ist ein automatisiertes oder halbautomatisches Produktionssystem zur Herstellung von essbaren Zapfen aus gebackenem Teig. Diese Waffeln werden häufig für Eiscreme verwendet, gefrorene Desserts, und Soft-Serve-Produkte.

Je nach Ausführung und Konfiguration, die Maschine produzieren kann:

- Waffel-Eistüten

- Zuckerkegel

- Flache Kegelkekse (zum Rollen)

- Kundenspezifische Kegelformen und -größen

Moderne Maschinen werden häufig in ein Gesamtsystem integriert Produktionslinie für Eistüten, Kombinieren des Teigmischens, Backen, Formen, Bildung, Kühlung, und Stapeln in einem einzigen kontinuierlichen Prozess.

Arten von Maschinen zur Herstellung von Eistütenkeksen

1. Maschine zur Herstellung von Waffel-Eistüten

Eine Waffeltütenmaschine produziert dünne Waffeln, knusprige Waffeln mit leichter Textur. Diese Maschinen verwenden Backplatten, um flüssigen Teig zu flachen Waffeln zu backen, die dann mithilfe von Formformen zu Kegeln gerollt werden.

Hauptmerkmale:

- Dünne und knackige Kegelstruktur

- Hohe Produktionsgeschwindigkeit

- Geeignet für die Massenproduktion

2. Maschine zur Herstellung von Zuckerkeksen

Zuckertüten sind dicker, süßer, und knuspriger als Waffeltüten. A Maschine zur Herstellung von Zuckerkeksen Verwendet Teig mit höherem Zuckergehalt und tiefere Backformen.

Vorteile:

- Starke Struktur, Ideal für Harteis

- Attraktive goldene Farbe

- Premium-Marktpositionierung

3. Automatische Maschine zur Herstellung von Eiskeksen

Ein Automatische Maschine zur Herstellung von Eiskeksen minimiert den Arbeitsaufwand und maximiert den Output. Es integriert eine SPS-Steuerung, automatische Teigzuführung, Temperaturregulierung, und Kegelstapelung.

Vorteile:

- Stabile Qualität

- Reduzierte Arbeitskosten

- Geeignet für große Fabriken

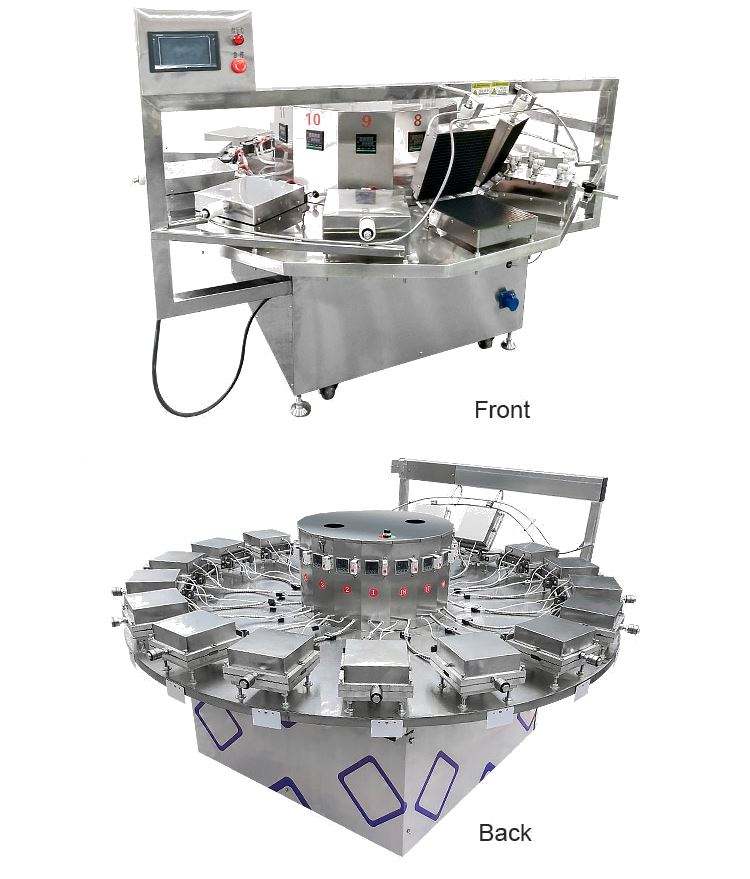

Hauptkomponenten einer Maschine zur Herstellung von Eiskeksen

Ein komplettes Eistüten-Keksmaschine besteht typischerweise aus den folgenden Teilen:

Teigmischsystem

Sorgt für eine gleichmäßige Mehlmischung, Zucker, Öl, Wasser, und Zusatzstoffe, um eine gleichbleibende Kegelqualität zu erreichen.

Backplatten und Formen

Präzisionsgefertigte Platten bestimmen die Kegeldicke, Muster, und Form. Platten bestehen normalerweise aus Gusseisen oder lebensmittelechtem Aluminium.

Heizsystem

Kann elektrisch sein, Gas, oder Hybrid. Eine genaue Temperaturregelung gewährleistet ein gleichmäßiges Backen und verhindert ein Anbrennen.

Kegelformeinheit

Rollt oder presst gebackene Waffeln automatisch in Kegelformen mit hoher Konsistenz.

Kühl- und Entladesystem

Ermöglicht das Abkühlen und Aushärten der Tüten vor dem Stapeln oder Verpacken.

Kontrollsystem

Über die SPS-Touchscreen-Schnittstelle können Bediener Parameter wie die Backzeit anpassen, Temperatur, und Geschwindigkeit.

Herstellungsprozess von Eiskeksen

Der Produktionsprozess eines Eistüten-Keksmaschine erfolgt in mehreren präzisen Schritten:

- Zutatvorbereitung

Mehl, Zucker, Wasser, Öl, und Aromastoffe werden nach Rezept zubereitet. - Teig mischen

Die Zutaten werden glatt gemischt, gleichmäßiger Teig ohne Klumpen. - Teigablagerung

Der Teig wird in präzisen Mengen auf erhitzte Backplatten gegeben. - Backen

Der Teig wird bei kontrollierter Temperatur zu dünnen Waffeln oder Waffelschalen gebacken. - Bildung

Heiße Waffeln werden mithilfe von Formen oder Rollmechanismen zu Kegeln geformt. - Kühlung

Geformte Waffeln werden abgekühlt, um ihre Form und Knusprigkeit zu bewahren. - Stapeln und Verpacken

Fertige Tüten werden zum Verpacken automatisch oder manuell gestapelt.

Technische Spezifikationen (Typische Reichweite)

Die technischen Daten variieren je nach Modell, ein Standard Eistüten-Keksmaschine kann beinhalten:

- Produktionskapazität: 3,000–12.000 Zapfen/Stunde

- Stromverbrauch: 8–35 kW

- Heizmethode: Elektrisch / Gas

- Kegelhöhenbereich: 90–150 mm

- Kegeloberdurchmesser: 40–75 mm

- Kontrollsystem: SPS mit Touchscreen

- Material: Edelstahl mit Lebensmitteln

Vorteile der Verwendung einer Maschine zur Herstellung von Eistütenkeksen

Hohe Produktionseffizienz

Automatisierte Maschinen steigern den Ausstoß im Vergleich zur manuellen Herstellung von Tüten deutlich.

Gleichbleibende Produktqualität

Gleichmäßiges Backen und Formen sorgen für eine gleichmäßige Größe, Farbe, und Textur.

Senkung der Arbeitskosten

Automatisierung verringert die Abhängigkeit von qualifizierten Arbeitskräften.

Anpassungsfähigkeit

Mithilfe verschiedener Formen können Hersteller Kegel unterschiedlicher Größe und Muster herstellen.

Einhaltung der Lebensmittelsicherheit

Moderne Maschinen erfüllen internationale Lebensmittelhygiene- und Sicherheitsstandards.

Anwendungen und Marktnachfrage

Der Eistüten-Keksmaschine ist weit verbreitet in:

- Eisfabriken

- Gefrorene Dessertpflanzen

- Bäckereien und Keksfabriken

- Herstellung von Private-Label-Kegeln

- Exportorientierte Lebensmittelverarbeitungsbetriebe

Mit steigendem Eiskonsum in Asien, dem Nahen Osten, Afrika, und Lateinamerika, Nachfrage nach Zuverlässigkeit Maschinen zur Herstellung von Eistüten wächst weiter.

So wählen Sie die richtige Eiswaffel-Keksmaschine aus

Bei der Auswahl einer Maschine, Berücksichtigen Sie die folgenden Faktoren:

Produktionskapazität

Passen Sie die Maschinenleistung an Ihre aktuellen und zukünftigen Produktionsanforderungen an.

Kegeltyp

Bestimmen Sie, ob Sie Waffeltüten benötigen, Zuckerkegel, oder beides.

Automatisierungsstufe

Wählen Sie zwischen halbautomatischen und vollautomatischen Modellen.

Energieverbrauch

Bewerten Sie die Betriebskosten anhand der Strom- und Heizart.

Kundendienst

Zuverlässiger technischer Support und Ersatzteilverfügbarkeit sind unerlässlich.

Investitions- und Rentabilitätsanalyse

Investieren in ein Eistüten-Keksmaschine bietet attraktive Renditen:

- Rohstoffe sind kostengünstig und weit verbreitet

- Fertige Zapfen haben einen hohen Mehrwert

- Starke Nachfrage seitens der Eishersteller

- Kurze Amortisationszeit für mittlere- und Großserienproduktion

Für viele Hersteller, Die Maschine kann innerhalb von 12–24 Monaten die Gewinnschwelle erreichen, je nach Produktionsvolumen und Marktpreisen.

Wartungs- und Betriebstipps

Um eine langfristige Leistung sicherzustellen:

- Backplatten täglich reinigen

- Überprüfen Sie die Heizelemente regelmäßig

- Bewegliche Teile nach Plan schmieren

- Schulung der Bediener ordnungsgemäß

- Verwenden Sie standardisierte Rezepte

Eine ordnungsgemäße Wartung verlängert die Lebensdauer der Maschine und sorgt für eine gleichbleibende Kegelqualität.

Zukünftige Trends bei Maschinen zur Herstellung von Eistütenkeksen

Die Branche bewegt sich in Richtung:

- Energieeffiziente Heizsysteme

- Intelligente SPS- und IoT-Integration

- Höhere Automatisierung und Robotik

- Nachhaltige Materialien und umweltfreundliche Produktion

Hersteller übernehmen fortschrittliche Technologien Maschinen zur Herstellung von Eiskeksen wird einen Wettbewerbsvorteil auf den globalen Märkten erlangen.

Maschine zur Herstellung von Eiskeksen

Ein Eistüten-Keksmaschine ist ein zentraler Vermögenswert für jedes Unternehmen, das sich mit der Herstellung von Eiscreme und Tiefkühldesserts beschäftigt. Mit Effizienzvorteilen, Qualität, Skalierbarkeit, und Rentabilität, Diese Maschinen spielen eine entscheidende Rolle in der modernen Lebensmittelherstellung.

Durch die Wahl der richtigen Konfiguration und des richtigen Lieferanten, Hersteller können eine zuverlässige bauen Produktionslinie für Eistüten das die Marktnachfrage erfüllt und langfristiges Wachstum unterstützt.

Wenn Sie planen, in den Markt für Eistüten einzusteigen oder dort zu expandieren, Investition in eine hochwertige Eistüten-Keksmaschine ist eine strategische Entscheidung mit großem kommerziellen Potenzial.