In der modernen Lebensmittelindustrie, die Nachfrage nach Knoblauchschälmaschine kommerziell Modelle ist deutlich gewachsen. Diese Maschinen sind für die schnelle Verarbeitung großer Mengen Knoblauch konzipiert, hygienisch, und das mit minimalem Handarbeitsaufwand. In diesem Artikel werden die wesentlichen Aspekte kommerzieller Knoblauchschälmaschinen untersucht, einschließlich ihrer Typen, Long-Tail-Keyword-Anwendungen, Arbeitsprinzipien, Technische Spezifikationen, und Kauftipps.

Einführung in industrielle Knoblauchschällösungen

Was ist eine Knoblauchschälmaschine für den gewerblichen Gebrauch??

A Knoblauchschälmaschine kommerziell Das Modell bezieht sich auf ein automatisiertes Gerät, mit dem die Schale von Knoblauchzehen in großen Mengen entfernt wird. Im Gegensatz zum manuellen Peeling, Diese Maschinen nutzen den Luftstrom, Reibung, oder Klingentechnologie, um eine hohe Effizienz bei minimaler Schädigung des Knoblauchs zu erreichen.

Arten von Knoblauchschälmaschinen, kommerzielle Modelle

Pneumatische Knoblauchschälmaschine für die Hochgeschwindigkeitsverarbeitung

Einer der häufigsten Typen ist der pneumatische Knoblauchschälmaschine, bei dem Knoblauchzehen mit Druckluft geschält werden. Es ist ideal für Lebensmittelverarbeitungsbetriebe, die einen Hochgeschwindigkeits- und kontinuierlichen Betrieb erfordern.

Vorteile:

- Kein Wasserverbrauch

- Minimaler Knoblauchschaden

- Hohe Produktivität (bis zu 600–1000 kg/h)

Knoblauchschalenentferner in Trommelform für die Massenproduktion

A Knoblauchschalenentferner in Trommelform verfügt über ein rotierendes Fass, in dem Knoblauch durch Reibung gewirbelt und geschält wird. Dieser Typ ist für Mitte geeignet- bis hin zu großen Produktionsumgebungen.

Knoblauchzehenschäler für Verarbeitungslinien

A Knoblauchzehenschälmaschine wird häufig zusammen mit der Spaltung in Knoblauchverarbeitungslinien integriert, Schneiden, oder Trocknungsmaschinen. Diese sind je nach Kapazität und Nutzung anpassbar.

Funktionsprinzip kommerzieller Knoblauchschälmaschinen

Schälsystem mit Luftkompressorantrieb

In pneumatischen Systemen, Knoblauchzehen werden in eine Kammer geleitet, wo Hochdruckluft von der Schale abbläst. Diese Maschinen dienen zum Trennen von Knoblauchschalen und -zehen mithilfe der Luftstromdynamik und eines internen Schälzylinders.

Reibungsbasiertes mechanisches Peeling

Einige handelsübliche Knoblauchschäler verwenden Gummiwalzen oder Schleifbürsten, die die Knoblauchschale sanft abreiben. Allerdings etwas weniger hygienisch als Luftmaschinen, Sie bieten eine hohe Leistung und sind einfacher zu warten.

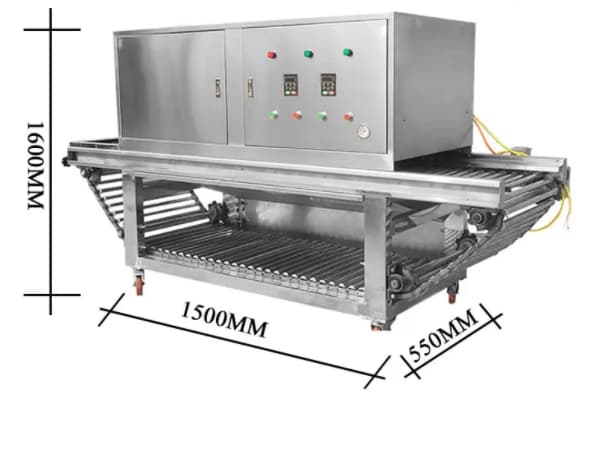

Technische Spezifikationen kommerzieller Knoblauchschälmaschinen

| Modell | Kapazität (kg/h) | Leistung (kW) | Anforderungen an den Luftkompressor | Material | Schälrate (%) | Größe (mm) | Gewicht (kg) |

|---|---|---|---|---|---|---|---|

| GP-100 | 100 | 0.2 | 0.75–1,0 MPa | Ss 304 | ≥95 % | 650×550×850 | 70 |

| GP-300 | 300 | 0.3 | 0.75–1,0 MPa | Ss 304 | ≥96 % | 950×650×1050 | 130 |

| GP-500 | 500 | 0.4 | 0.75–1,0 MPa | Ss 304 | ≥96 % | 1150× 800 × 1200 | 180 |

| GP-1000 | 1000 | 0.75 | 0.75–1,0 MPa | Ss 304 | ≥97 % | 1350×1000×1300 | 250 |

Alle kommerziellen Knoblauchschälmaschinen bestehen aus lebensmittelechtem Edelstahl und entsprechen den HACCP- und CE-Standards.

Vorteile der Verwendung einer Knoblauchschälmaschine in Großküchen

Zeit- und Arbeitsersparnis

Das manuelle Schälen von Knoblauch kann äußerst arbeitsintensiv sein. A Knoblauchschälmaschine kommerziell Einheit kann sich ablösen 1000 kg Knoblauch pro Stunde, Reduzierung des Arbeitsbedarfs und Senkung der Betriebskosten.

Hohe Effizienz und minimaler Abfall

Mit Schälraten von über 95%, Diese Maschinen stellen sicher, dass die maximale Menge an Knoblauch verwendet werden kann, mit minimalem Schaden und Abfall.

Hygiene und Sicherheit

Die Maschinen sind so konzipiert, dass sie den Lebensmittelsicherheitsstandards entsprechen, Minimierung des Kontaminationsrisikos, insbesondere in der kommerziellen Lebensmittelproduktion.

Anwendungen handelsüblicher Maschinen zur Knoblauchhautentfernung

Industrielle Knoblauchverarbeitungsanlagen

Fabriken, die Knoblauchpaste herstellen, Knoblauchöl, oder dehydrierter Knoblauch werden üblicherweise verwendet Knoblauchschälmaschine kommerziell Ausrüstung als Erststufenprozessor.

Zentralküchen und Cateringunternehmen

Großküchen, die vorgeschnittene oder vorgewürzte Lebensmittel zubereiten, profitieren von kommerziellen Knoblauchschälern aufgrund ihres großen Fassungsvermögens.

Hersteller von Knoblauchpaste und -sauce

Diese Maschinen sind eine Schlüsselkomponente in der Produktionslinie für Knoblauchpüree oder -sauce, wo geschälter Knoblauch unerlässlich ist.

So wählen Sie die beste Knoblauchschälmaschine für den gewerblichen Gebrauch aus

Bewerten Sie Ihr Produktionsvolumen

Wählen Sie eine Maschine mit der richtigen Kapazität für Ihr Unternehmen. Kleine Restaurants könnten es brauchen 100 kg/h, während große Pflanzen erfordern 1000 kg/h oder mehr.

Bewerten Sie den Strom- und Luftbedarf

Am meisten kommerzielle Knoblauchschälmaschinen benötigen einen Luftkompressor. Stellen Sie sicher, dass Ihre Einrichtung die Spezifikationen des Kompressors unterstützen kann.

Achten Sie auf Haltbarkeit und Materialqualität

Edelstahlkonstruktion (Ss 304 oder SS 316) ist ein Muss für Hygiene und Langlebigkeit.

Berücksichtigen Sie Wartung und Ersatzteile

Entscheiden Sie sich für Modelle, die einfachen Zugang zu Teilen und Wartungsunterstützung bieten, insbesondere bei täglicher Nutzung im gewerblichen Betrieb.

Kommerzielle Modelle von Knoblauchschälmaschinen vs. Knoblauchschäler für den Haushalt

| Besonderheit | Kommerzieller Schäler | Haushaltsschäler |

| Kapazität | 100–1000 kg/h | 0.5–2 kg/h |

| Stromquelle | Elektrisch + Luft | Manueller oder kleiner Elektromotor |

| Baumaterial | Edelstahl | Kunststoff oder minderwertiges Metall |

| Preisklasse | $800 - - $5000 | $10 - - $100 |

| Anwendungen | Industriell, Lebensmittelfabriken | Heimküchen, Restaurants |

| Automatisierungsstufe | Vollautomatisch | Handbuch oder halbautomatisch |

Häufig gestellte Fragen (FAQs)

Wie hoch ist die durchschnittliche Schälgeschwindigkeit einer kommerziellen Knoblauchschälmaschine??

Die meisten Maschinen haben eine Schäleffizienz von 95% oder höher, je nach Knoblauchsorte und Maschinentyp.

Kann ich für nassen Knoblauch eine Knoblauchschälmaschine verwenden??

Am meisten kommerzielle Knoblauchschälmaschinen sind für trockenen Knoblauch konzipiert. Nasser Knoblauch kann die Effizienz beeinträchtigen und das Luftstromsystem verstopfen.

Beschädigen diese Maschinen den Knoblauch??

NEIN. Hochwertige Maschinen sind so konstruiert, dass Druckstellen und Brüche minimiert werden. Das Peeling erfolgt schonend durch Luft- oder sanfte Reibung.

Im Lieferumfang der Maschine ist ein Luftkompressor enthalten?

In den meisten Fällen, Knoblauchschälmaschine kommerziell Die Geräte enthalten keinen Luftkompressor, Die Hersteller empfehlen jedoch in der Regel kompatible Modelle.

Wie reinige ich eine Knoblauchschälmaschine??

Zerlegen Sie einfach die wichtigsten Teile und spülen Sie sie mit warmem Wasser ab. Trennen Sie vor der Reinigung immer die Stromversorgung und die Luftzufuhr.

Ausschreibungen und Antworten für gewerbliche Käufer von Knoblauchschälmaschinen

1. Wir brauchen eine Knoblauchschälmaschine für 300 kg/h Kapazität. Können Sie Spezifikationen und ein Angebot bereitstellen??

Ja, Unser Modell GP-300 unterstützt 300 kg/h. Leistung: 0.3 kW, Luftdruck: 0.75–1,0 MPa, Schälrate ≥96 %, Größe: 950×650×1050 mm. Das Angebot basiert auf dem Zielhafen und den Verpackungsanforderungen.

2. Ist Ihr kommerzieller Knoblauchschäler für den Einsatz in einer Reinraumumgebung geeignet??

Ja. Unsere Maschinen werden mit SUS gebaut 304 Edelstahl- und versiegelte Ausführungen, geeignet für GMP-konforme Reinräume.

3. Wofür ist die Lieferzeit? 2 Einheiten des Modells GP-1000 nach Mexiko?

Die Produktionszeit beträgt 7–10 Tage. Der Seetransport nach Mexiko dauert 25–35 Tage. Wir können CIF- oder DDP-Konditionen vereinbaren.

4. Bieten Sie eine komplette Knoblauchverarbeitungslinie einschließlich der Spaltung an?, Peeling, und schneiden?

Ja. Wir bieten schlüsselfertige Lösungen mit Lampentrennschalter, Schäler, Allesschneider, Pastenmühle, Trockner, und Verpackungsmaschine.

5. Kann Ihre Knoblauchschälmaschine dauerhaft betrieben werden? 8+ Std.?

Ja. Unsere kommerziellen Knoblauchschäler sind industrietauglich und können länger laufen 8 Stunden pro Schicht bei ordnungsgemäßer Wartung.

6. Bieten Sie Installationsunterstützung vor Ort in den VAE an??

Ja. Wir bieten die Entsendung von Technikern für Installation und Schulung in die Vereinigten Arabischen Emirate und andere Länder an. Videounterstützung ist ebenfalls verfügbar.

7. Können wir Ihren handelsüblichen Knoblauchschäler für die Vorverarbeitung der schwarzen Knoblauchproduktion verwenden??

Ja. Unser Schäler entfernt die Haut sanft, Der Knoblauch bleibt intakt – ideal für die Fermentation.

8. Über welche Zertifizierungen verfügen Ihre Maschinen?? (Ce, ISO, usw.)

Wir bieten CE, ISO 9001:2015, und optionale UL/CSA-Zertifizierungen. Materialerklärungen in FDA-Qualität verfügbar.

9. Ist es möglich, diese Maschine in ein Knoblauchwaschsystem zu integrieren??

Ja. Wir können integrierte Automatisierungssysteme einschließlich Knoblauchwaschmaschinen bereitstellen, Förderer, und Trockner.

10. Wir benötigen eine Knoblauchschälmaschine, die mit variablem Luftdruck arbeiten kann. Passen Sie solche Modelle an??

Ja. Wir bieten druckgeregelte Systeme und kundenspezifische Konfigurationen für Anlagen mit unterschiedlicher Luftversorgung.

Abschluss

Für Lebensmittelhersteller und Verarbeitungsbetriebe, Investieren in a Knoblauchschälmaschine kommerziell Einheit ist eine kluge und notwendige Entscheidung. Es bietet eine hohe Effizienz, Hygiene, und Skalierbarkeit – wesentliche Faktoren für eine wettbewerbsfähige Lebensmittelproduktion.

Egal, ob Sie eine große Knoblauchpastenfabrik oder eine zentralisierte Großküche betreiben, Diese Maschinen werden Ihre Produktionslinie bereichern, Arbeit reduzieren, und die Produktqualität verbessern.

Kommerzielle Knoblauchschälmaschine Lösungen sind nicht nur ein Upgrade – sie verändern das Spielgeschehen.