Einführung

Chocolate begins its life in the humble cacao bean. But before it becomes the smooth, rich delicacy we all know, the bean must go through several stages of transformation — one of the most important being Schleifen. Der cacao grinder machine is a key piece of equipment in this process, responsible for turning roasted cacao nibs into fine chocolate liquor.

For chocolate manufacturers, small-scale producers, and even artisanal chocolatiers, understanding how a cacao grinder machine works, its uses, and its benefits can dramatically improve product quality and efficiency. In diesem Artikel, we will explore everything you need to know about the cacao grinder machine — from its working principle and applications to technical specifications and selection tips.

1. What Is a Cacao Grinder Machine?

A cacao grinder machine, sometimes referred to as a chocolate melanger oder Kakaomahlmaschine, is used to finely grind roasted cacao nibs into a smooth paste known as Kakaomasse oder cocoa mass. This stage is crucial in the chocolate-making process, as the grinding determines the final texture, smoothness, and flavor profile of the chocolate.

These machines can range from small tabletop units designed for home or small-scale chocolate makers to large industrial grinders used in professional chocolate factories.

Typischerweise, a cacao grinder machine consists of:

- A stainless steel drum or chamber

- Grinding stones or steel blades

- Motor and gearbox

- Temperature control system

The grinding process breaks down cacao nibs, releasing their natural cocoa butter and transforming them into a creamy, homogenous paste ready for refining and conching.

2. How Does a Cacao Grinder Machine Work?

The working principle of a cacao grinder machine is simple yet effective. The roasted cacao nibs are fed into the grinding chamber, where two heavy grinding stones or blades crush and shear them continuously.

Here’s the process step-by-step:

- Füttern

The roasted and winnowed cacao nibs are placed into the hopper. - Grinding and Shearing

The rotating stones or stainless-steel blades grind the nibs, releasing cocoa butter and converting the mixture into a thick paste. - Continuous Refining

The machine continues to grind for several hours, refining the particle size to 20 microns or less. - Temperature Regulation

Some advanced cacao grinders include temperature sensors and water-cooling systems to prevent overheating and preserve flavor. - Entladung

Once the desired fineness is achieved, the cocoa liquor is discharged for further processing into chocolate bars, Pulver, or other cocoa products.

3. Main Uses of a Cacao Grinder Machine

Der primary use of a cacao grinder machine is to grind cacao nibs into chocolate liquor, but it can also serve several other purposes in the food industry.

3.1 Chocolate Production

Cacao grinder machines are essential in making all kinds of chocolate — dark, Milch, or white. After grinding, the cocoa mass is mixed with sugar, Milchpulver, and cocoa butter to produce chocolate with a rich, silky texture.

3.2 Cocoa Butter Extraction

The finely ground cocoa liquor is pressed to extract cocoa butter, an essential ingredient for chocolate, Kosmetika, and pharmaceuticals.

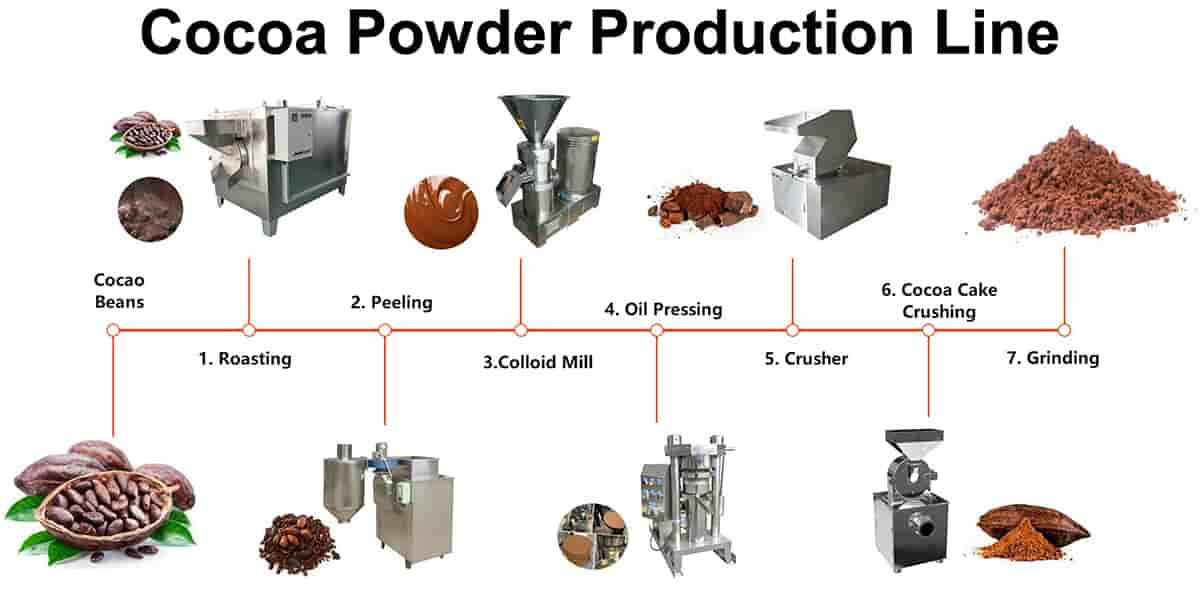

3.3 Cocoa Powder Manufacturing

After extracting cocoa butter, the remaining solid is dried and milled into cocoa powder used for baking, Getränke, and desserts.

3.4 Nut and Seed Grinding

Some versatile cacao grinder machines can also grind peanuts, Mandeln, Sesam, or other nuts — ideal for making nut butters or pastes.

3.5 Beverage and Dessert Processing

In beverage factories, cacao grinders are used to make hot chocolate bases, chocolate sauces, and syrups.

4. Advantages of Using a Cacao Grinder Machine

Investing in a quality cacao grinder machine offers several benefits for chocolate producers:

4.1 Konsistente Partikelgröße

Uniform grinding ensures a smooth mouthfeel and premium texture in the final chocolate product.

4.2 Enhanced Flavor Development

Continuous grinding releases cocoa butter evenly, allowing for better flavor integration during conching.

4.3 Effizienz und Produktivität

Modern machines can grind large batches continuously, Zeit- und Arbeitskosten sparen.

4.4 Hygienisches und langlebiges Design

Most industrial cacao grinders are made of food-grade stainless steel, easy to clean and corrosion-resistant.

4.5 Energieeffizienz

Advanced models come with energy-saving motors and temperature control systems, Senkung der Betriebskosten.

5. Structure and Components of a Cacao Grinder Machine

A typical cacao grinder machine consists of several main parts:

| Komponente | Funktion |

|---|---|

| Schleifkammer | Holds cacao nibs and ensures consistent grinding |

| Grinding Stones or Blades | Shear and crush the nibs into fine particles |

| Motor | Provides mechanical power for grinding |

| Getriebe | Controls rotational speed and torque |

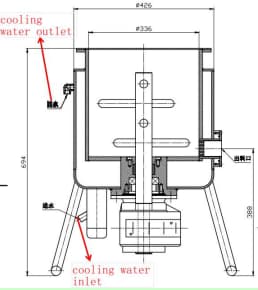

| Kühlsystem | Maintains stable grinding temperature |

| Bedienfeld | Allows operation adjustments and monitoring |

| Ableitungsventil | Releases finished cocoa liquor |

6. Technische Parameter (Beispiel: DT Food Machine Model CGM-50)

| Modell | CGM-50 |

|---|---|

| Kapazität | 50 kg/h |

| Leistung | 7.5 kW |

| Mahlfeinheit | ≤ 20 Mikrometer |

| Material | Edelstahl SUS304 |

| Gewicht | 280 kg |

| Stromspannung | 380V / 50Hz |

| Cooling Type | Wasserkühlung |

| Abmessungen | 900 × 700 × 1200 mm |

This model is suitable for small to medium-scale chocolate manufacturers looking for high efficiency and stable performance.

7. How to Choose the Right Cacao Grinder Machine

When selecting a cacao grinder machine for your business, Berücksichtigen Sie die folgenden Faktoren:

- Produktionskapazität – Choose according to your daily or monthly output.

- Mahlfeinheit – The finer the grind, the smoother the chocolate texture.

- Material and Durability – Opt for stainless steel or food-grade components.

- Temperaturkontrolle – Prevents overheating, which can ruin flavor.

- Leichte Reinigung – Removable drums and stones simplify sanitation.

- After-Sales-Service – Check for warranty, Ersatzteile, und technischer Support.

If you are starting a chocolate-making business, a semi-automatic cacao grinder may be enough. For large-scale chocolate factories, a fully automatic continuous grinder is recommended.

8. Maintenance and Cleaning Tips

Proper maintenance ensures long machine life and consistent grinding quality:

- Clean the drum and stones after every batch.

- Avoid overloading the grinder beyond rated capacity.

- Lubricate bearings regularly.

- Check motor belts and gearbox for wear.

- Keep the cooling system functional.

- Store in a dry and clean environment.

Regular servicing can extend the grinder’s lifespan by several years.

9. Cacao Grinder Machine Price Range

Der price of a cacao grinder machine hängt von der Kapazität ab, Automatisierungsstufe, und Material.

| Maschinenart | Kapazität (kg/h) | Ca.. Preisklasse (USD) |

|---|---|---|

| Small-Scale Grinder | 10–30 kg/h | $800 - - $2,500 |

| Medium-Scale Grinder | 50–100 kg/h | $3,000 - - $8,000 |

| Industrial Grinder | 200–500 kg/h | $10,000 - - $25,000+ |

Prices may vary depending on additional features like temperature control, water cooling, and PLC automation.

10. Why Choose DT Food Machine as Your Cacao Grinder Machine Supplier

DT Food Machine Co., GmbH. is a professional manufacturer of cacao processing and chocolate-making equipment with over 15 jahrelange Erfahrung.

10.1 Quality Manufacturing

All machines are made of high-quality stainless steel und einhalten CE and ISO standards, ensuring durability and food safety.

10.2 Customization Available

We offer customized cacao grinder machines to suit your specific capacity, Stromspannung, and design needs.

10.3 Technische Unterstützung

DT Food Machine provides complete installation guidance, After-Sales-Service, und Ersatzteile to keep your production running smoothly.

10.4 Global Export

Our cacao grinder machines are exported to more than 40 Länder, einschließlich der USA, Mexiko, Peru, Indonesien, and Ghana.

11. Häufig gestellte Fragen (FAQ)

Q1: Can the cacao grinder machine be used for other nuts?

Ja, it can grind peanuts, Mandeln, Sesam, and cashews with excellent smoothness.

Q2: How fine does it grind cacao nibs?

It can achieve a particle size of 15–20 microns, ideal for smooth chocolate texture.

Q3: How long does the grinding process take?

It usually takes 6–12 hours, depending on the desired fineness and batch size.

Q4: Do you provide spare parts?

Ja, DT Food Machine provides full spare parts and maintenance kits for all models.

Q5: Can I customize machine capacity?

Absolut. We can design machines from 10 kg/h up to 1000 kg/h according to your production scale.

Cacao Grinder Machine

A cacao grinder machine is the heart of chocolate production — transforming cacao nibs into smooth, rich cocoa liquor ready for refinement. Whether you are a small artisan or a large industrial chocolate maker, choosing the right grinder will directly impact your product’s quality, Geschmack, und Effizienz.

By understanding how the machine works, its applications, und Wartung, you can optimize your production process and ensure consistent, high-quality results.

Wenn Sie auf der Suche nach einem sind reliable cacao grinder machine manufacturer, DT-Lebensmittelmaschine offers advanced technology, durable design, and professional service to help you grow your chocolate business.