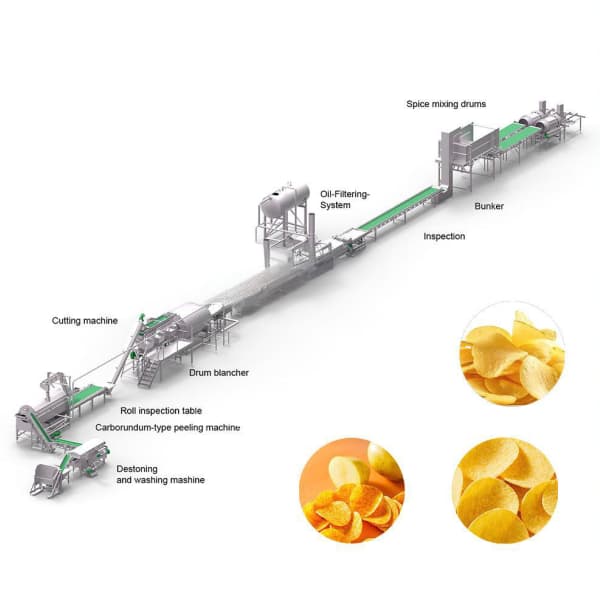

أ fully automatic potato chips production line is a complete system of interconnected machines designed to process raw potatoes into finished potato chips with minimal manual intervention.

The line integrates several stages — from washing, تقشير, and slicing to frying, توابل, and packaging — all controlled through automated systems that ensure hygiene, كفاءة, وجودة المنتج متسقة.

This type of production line is ideal for:

- Commercial snack manufacturers

- Food factories and distributors

- Large-scale potato processing plants

- Entrepreneurs in the snack food industry

مع آلة الغذاء دي تي’s engineering expertise, the entire process is optimized to reduce labor costs, minimize waste, and maintain a uniform flavor and texture across every batch.

Working Process of the Potato Chips Production Line

ال automatic potato chips making machine line consists of several key stages. Each step plays a vital role in producing crispy, high-quality chips.

1. ماكينة غسل وتقشير البطاطس

Fresh potatoes are loaded into the washing and peeling machine, which removes mud, الحجارة, and outer skin using a combination of brushes and water spray.

- سعة: 300-2000 كجم/ساعة

- مادة: الفولاذ المقاوم للصدأ SUS304

- يتحكم: Adjustable water flow and brush speed

2. Potato Slicing Machine

The clean potatoes are transferred into the potato slicing machine, which cuts them into thin, uniform slices.

- Slice thickness: 0.8–2.0 mm adjustable

- Cutting speed: 300-800 كجم/ساعة

- سمات: Sharp blades, minimal breakage rate

3. آلة الشطف والتبييض

The sliced potatoes are rinsed to remove surface starch, then blanched at a controlled temperature to improve color, ذوق, والملمس.

- Blanching temperature: 80-95 درجة مئوية

- Duration: 1–3 minutes

- وظيفة: Prevents oxidation and ensures crispiness

4. آلة نزح المياه

بعد السلق, the slices are dewatered to remove excess moisture before frying. This step prevents oil splashes and reduces oil consumption.

- سرعة: 800 دورة في الدقيقة

- Dewatering time: 30–60 seconds

- مادة: 304 الفولاذ المقاوم للصدأ

5. آلة القلي المستمرة

This is the heart of the potato chips processing line. ال مقلاة مستمرة fries the potato slices evenly under controlled temperature.

- Frying temperature: 160-180 درجة مئوية

- طريقة التدفئة: كهربائي, الغاز, أو الديزل

- Oil circulation system ensures consistent frying results

6. آلة deoiling

بمجرد المقلية, the chips are moved to the آلة deoiling to remove excess oil. This improves texture and shelf life.

- Speed adjustable

- Centrifugal system for efficient oil removal

7. آلة التوابل

The crispy potato chips are then mixed with flavor powders in the seasoning drum. Whether it’s barbecue, جبن, or classic salted flavor, the machine ensures even coating.

- Rotary drum design

- Adjustable rotation speed

- Compatible with automatic flavor dosing systems

8. Cooling and Packaging Machine

أخيراً, the chips are cooled and packed using a vertical packaging machine.

- وظائف: وزن, تعبئة, ختم, and labeling

- مواد التعبئة والتغليف: Aluminum foil or composite film

- Sealing type: Pillow bag or gusset bag

جدول المعلمات التقنية

| نموذج | سعة (كجم/ساعة) | قوة (كيلوواط) | أبعاد (م) | طريقة التدفئة | مادة |

|---|---|---|---|---|---|

| دي تي-300 | 300 | 60 | 12 × 2 × 2.5 | كهربائي | SUS304 |

| دي تي-500 | 500 | 90 | 15 × 2.5 × 2.8 | غاز / كهرباء | SUS304 |

| دي تي-1000 | 1000 | 150 | 18 × 3 × 3 | الغاز / الديزل | SUS304 |

| DT-1500 | 1500 | 200 | 20 × 3.5 × 3.2 | الغاز | SUS304 |

| دي تي-2000 | 2000 | 250 | 22 × 4 × 3.5 | الغاز / الديزل | SUS304 |

All models can be customized according to customer requirements (سعة, تَخطِيط, heating source, الجهد االكهربى, إلخ.).

Advantages of DT Food Machine Potato Chips Production Line

1. Full Automation and Easy Operation

The entire automatic potato chips plant is PLC-controlled, meaning you can monitor and adjust every process through a touch-screen interface.

2. تصميم صحي ودائم

All components are made of food-grade الفولاذ المقاوم للصدأ SUS304, ensuring corrosion resistance and easy cleaning.

3. كفاءة الطاقة

Our system uses optimized heat recovery and oil filtration technology to minimize energy and oil consumption.

4. جودة المنتج متسقة

Uniform slicing, accurate temperature control, and even seasoning guarantee stable taste and color.

5. Customizable Solutions

We provide tailor-made designs for different capacities, workshop layouts, and local market demands.

6. Low Maintenance

High-quality motors, precision bearings, and modular components ensure long-term reliability and easy maintenance.

Applications of the Potato Chips Making Machine

ال fully automatic potato chips production line can be used to produce:

- Classic fried potato chips

- Crispy potato crisps

- Sweet potato chips

- Banana or cassava chips (optional modifications)

ويستخدم على نطاق واسع في:

- مصانع الوجبات الخفيفة

- Frozen food processing plants

- Commercial catering supply chains

- Export-oriented food production businesses

How to Start a Potato Chips Factory

If you are planning to start a commercial potato chips factory, here are the key steps:

- أبحاث السوق – Identify demand and target audience.

- Production Capacity Planning – Choose the right model (على سبيل المثال, 300 kg/h or 1000 كجم/ساعة).

- Space & المرافق – Ensure proper electricity, الغاز, and water supply.

- مصادر المواد الخام – Use high-quality, fresh potatoes.

- Machine Installation – DT Food Machine provides layout design, تثبيت, and training.

- ضبط الجودة – Follow hygiene standards and consistent production.

- التغليف & العلامة التجارية – Create attractive packaging for your target market.

With DT Food Machine’s one-stop service, you can start your potato chips production easily and efficiently.

لماذا تختار DT Food Machine?

As a leading potato chips production line manufacturer, DT Food Machine offers comprehensive support and superior quality equipment.

Our Core Strengths

- زيادة 15 سنوات من الخبرة في التصنيع

- احترافي ص&D and after-sales team

- ISO and CE certified الآلات

- Global installation and technical training service

- تصدير إلى أكثر من 60 بلدان, بما في ذلك الولايات المتحدة الأمريكية, الهند, المكسيك, and South Africa

Customer Service

نحن نقدم:

- تصميم تخطيط المصنع

- Machine customization

- تدريب المشغلين

- توريد قطع الغيار

- Lifetime technical support

Optional Equipment for Expansion

To further enhance production, you can integrate additional equipment:

- Automatic Potato Sorting Machine

- نظام ترشيح الزيت

- Nitrogen Flushing Packaging Machine

- Automatic Weighing and Mixing Unit

- Continuous Belt Conveyor System

These upgrades can help expand your factory capacity and improve efficiency.

خط إنتاج رقائق البطاطس الأوتوماتيكي بالكامل

الاستثمار في أ خط إنتاج رقائق البطاطس الأوتوماتيكي بالكامل is the key to achieving high efficiency, جودة متسقة, and sustainable profits in the snack food industry.

في آلة الغذاء دي تي, we are committed to providing world-class potato chips processing solutions tailored to your production scale and market needs. Our advanced design, مواد متينة, and reliable after-sales support make us a trusted partner for global food manufacturers.

If you’re looking to start or upgrade your خط انتاج رقائق البطاطس, contact آلة الغذاء دي تي today — your reliable manufacturer of automatic potato chips making machines.