مقدمة لآلة صنع الكريب

أ ماكينة صنع الكريب هي آلة تجهيز أغذية احترافية مصممة لإنتاج الكريب بكفاءة, باستمرار, وصحيا. كريب, معروفة بملمسها الرقيق وتعدد استخداماتها, تحظى بشعبية كبيرة في المقاهي, أكشاك الطعام في الشوارع, محلات الحلوى, مطاعم الوجبات السريعة, الفنادق, ومصانع الأغذية الصناعية في جميع أنحاء العالم. مع استمرار الطلب الاستهلاكي في النمو, لم يعد إنتاج الكريب يدويًا كافيًا للشركات التي تتطلب إنتاجًا عاليًا, جودة موحدة, وكفاءة التكلفة.

هذا هو المكان ماكينة صنع الكريب التجارية, صانع الكريب الأوتوماتيكي, و ماكينة تصنيع الكريب الصناعية تصبح أدوات أساسية. تساعد هذه الآلات الشركات على تحسين الإنتاجية, تقليل تكاليف العمالة, وتقديم كريب موحد على نطاق واسع.

ما هي ماكينة صنع الكريب?

أ ماكينة صنع الكريب هي عبارة عن معدات غذائية متخصصة تعمل على أتمتة عملية توزيع الخليط, التدفئة, طبخ, وأحيانا تقليب الكريب. اعتمادا على مستوى الأتمتة, يمكن أن تتراوح من ماكينات الكريب الكهربائية نصف الأوتوماتيكية ل خطوط إنتاج الكريب الصناعي الأوتوماتيكية بالكامل.

تتضمن الأسماء البديلة الشائعة والكلمات الرئيسية الطويلة:

- ماكينة صنع الكريب الأوتوماتيكية

- ماكينة الكريب التجارية

- صانع الكريب الكهربائي للأعمال

- ماكينة كريب صناعية

- ماكينة تصنيع الكريب

- صانع كريب محترف

- ماكينة طبخ الكريب

تشير جميع هذه المصطلحات إلى المعدات المصممة لإنتاج الكريب بسمك ثابت, مقاس, والملمس.

كيف تعمل ماكينة صنع الكريب?

عملية العمل أ ماكينة صنع الكريب بسيطة ولكنها ذات كفاءة عالية:

- تغذية الخليط

يُسكب خليط الكريب يدويًا أو يتم إدخاله تلقائيًا في الماكينة من خلال قادوس أو نظام الجرعات. - انتشار الخليط

طبلة دوارة, بكرة الانتشار, أو تقوم لوحة التسخين المسطحة بتوزيع الخليط بالتساوي إلى طبقة دائرية رقيقة. - التدفئة والطبخ

تستخدم الآلة التسخين الكهربائي أو تسخين الغاز لطهي الكريب في درجة حرارة يمكن التحكم فيها. - التقليب أو التقشير

اعتمادا على النموذج, قد يتم قلب الكريب تلقائيًا أو تقشيره من الأسطوانة بعد الطهي. - التبريد والجمع

يتم جمع الكريب الجاهز يدويًا أو نقله إلى ناقل للتبريد والتعبئة.

تضمن هذه العملية الآلية طهيًا موحدًا, إخراج مستقر, ومعايير سلامة الغذاء العالية.

أنواع ماكينات صنع الكريب

1. ماكينة صنع الكريب اليدوية ونصف الأوتوماتيكية

أ ماكينة صنع الكريب نصف اوتوماتيك يتطلب عادةً صب الخليط يدويًا وإزالة الكريب ولكنه يعمل تلقائيًا على التسخين والتوزيع. هذه الآلات مثالية ل:

- المقاهي الصغيرة

- شاحنات الغذاء

- بائعي المواد الغذائية في الشوارع

- الشركات الناشئة

إنها مدمجة, سهل التشغيل, وبأسعار معقولة.

2. ماكينة صنع الكريب التجارية

أ ماكينة صنع الكريب التجارية تم تصميمه للاستخدام اليومي المستمر. إنه يقدم:

- قدرة انتاجية أعلى

- مواد متينة صالحة للطعام

- التحكم الدقيق في درجة الحرارة

- أداء مستقر

هذا النوع من صانع الكريب للأعمال التجارية يستخدم عادة في المطاعم, سلاسل الحلوى, ومراكز التسوق.

3. ماكينة صنع الكريب الأوتوماتيكية بالكامل

أ ماكينة صنع الكريب الأوتوماتيكية بالكامل يدمج تغذية الخليط, الانتشار, طبخ, والتفريغ في نظام واحد. وتشمل المزايا:

- الحد الأدنى من متطلبات العمالة

- الاتساق العالي

- الإنتاج المستمر

- مناسبة للكريب ذات الحجم القياسي

هذه الآلات مثالية للعمليات الغذائية المتوسطة والكبيرة.

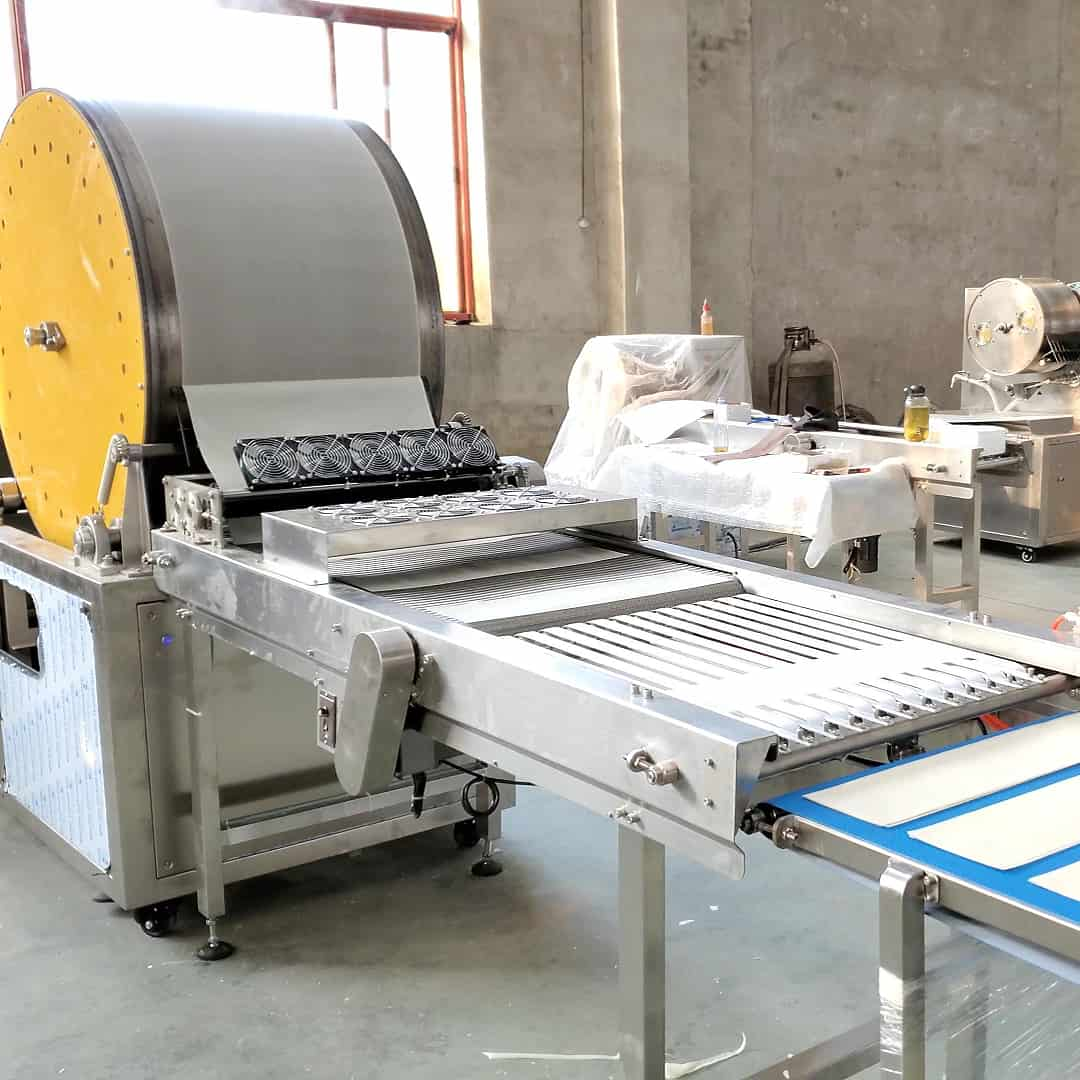

4. ماكينة تصنيع الكريب الصناعية

و ماكينة تصنيع الكريب الصناعية تم تصميمه للإنتاج على نطاق واسع ومصانع المواد الغذائية. غالبًا ما يعمل كجزء من خط انتاج الكريب ويمكن دمجها مع التبريد, التراص, وأنظمة التغليف.

وتشمل الميزات الرئيسية:

- قدرة انتاجية عالية

- نظام التحكم PLC

- طبل الطبخ المستمر

- سهولة التنظيف والصيانة

الميزات الرئيسية لآلة صنع الكريب

ذات جودة عالية ماكينة صنع الكريب يتضمن عادةً الميزات التالية:

- هيكل من الفولاذ المقاوم للصدأ بدرجة الطعام

- التحكم الدقيق في درجة الحرارة

- نظام توزيع الخليط الموحد

- سطح طهي غير لاصق

- التدفئة الموفرة للطاقة

- عملية مستقرة وآمنة

- سهولة التنظيف والصيانة

قد تشمل النماذج المتقدمة أيضًا:

- التحكم بشاشة اللمس PLC

- سمك كريب قابل للتعديل

- قطر قابل للتعديل

- نظام التراص التلقائي

تطبيقات آلة صنع الكريب

ال ماكينة صنع الكريب لديها مجموعة واسعة من التطبيقات في مختلف الصناعات:

صناعة الخدمات الغذائية

- المقاهي والمخابز

- محلات الحلويات

- مطاعم الوجبات السريعة

- الفنادق والمنتجعات

طعام الشارع والتجزئة

- شاحنات الغذاء

- أسواق ليلية

- أكشاك مراكز التسوق

صناعة تجهيز الأغذية

- إنتاج الكريب المجمد

- عبوة كريب جاهزة للأكل

- مطابخ مركزية

- شركات التموين

لأن الكريب يمكن أن يكون حلوًا أو مالحًا, ال ماكينة الكريب التجارية يدعم خيارات القائمة المتنوعة.

مميزات استخدام ماكينة صنع الكريب

1. كفاءة إنتاجية أعلى

بالمقارنة مع الطبخ اليدوي, أ آلة صنع كريب يزيد بشكل كبير من الإخراج والسرعة.

2. جودة المنتج متسقة

تضمن درجة الحرارة والانتشار الآلي سمكًا وملمسًا موحدًا للكريب.

3. انخفاض تكاليف العمالة

يمكن لمشغل واحد إدارة أجهزة متعددة, خفض نفقات التوظيف.

4. تحسين سلامة الأغذية

المواد الغذائية والعمليات الخاضعة للرقابة تلبي معايير النظافة.

5. قابلية التوسع لنمو الأعمال

من المحلات التجارية الصغيرة إلى المصانع الصناعية, تدعم آلات الكريب الإنتاج القابل للتطوير.

آلة صنع الكريب مقابل الطبخ اليدوي للكريب

| وجه | طبخ الكريب يدوياً | ماكينة صنع الكريب |

|---|---|---|

| الإخراج | قليل | عالي |

| تناسق | غير مستقر | زي مُوحد |

| تكلفة العمالة | عالي | قليل |

| صحة | المشغل يعتمد | تسيطر عليها |

| قابلية التوسع | محدود | ممتاز |

توضح هذه المقارنة بوضوح سبب تفضيل الشركات لـ آلة صنع الكريب التجارية أو الصناعية.

كيفية اختيار آلة صنع الكريب المناسبة

عند اختيار أ ماكينة صنع الكريب, النظر في العوامل التالية:

القدرة الإنتاجية

حدد عدد الكريب الذي يتطلبه عملك في الساعة.

مستوى الأتمتة

اختر بين شبه التلقائي, تلقائي, أو الآلات الصناعية.

مصدر الطاقة

آلات صنع الكريب الكهربائية أنظف وأسهل في التحكم, في حين أن نماذج الغاز قد تقلل من تكاليف التشغيل في بعض المناطق.

حجم الكريب وسمكه

تأكد من أن الماكينة تدعم قطر الكريب وسمكه المطلوب.

دعم بعد البيع

يعد الدعم الفني الموثوق به وتوافر قطع الغيار أمرًا بالغ الأهمية.

صيانة وتنظيف ماكينة صنع الكريب

الصيانة المناسبة تضمن عمر خدمة طويل وأداء مستقر:

- تنظيف سطح الطبخ يوميا

- فحص عناصر التسخين بانتظام

- فحص المكونات الكهربائية

- قم بتشحيم الأجزاء المتحركة إذا لزم الأمر

- اتبع إرشادات الشركة المصنعة

صيانة جيدة آلة صنع كريب يمكن أن تعمل بكفاءة لسنوات عديدة.

اتجاهات السوق لآلات صنع الكريب

السوق العالمية ل ماكينات تصنيع الكريب ينمو بسبب:

- ارتفاع الطلب على أغذية الشوارع

- توسيع سلاسل الحلوى

- زيادة الأتمتة في تجهيز الأغذية

- نمو أسواق الأغذية المجمدة والجاهزة للأكل

وتشمل الاتجاهات المستقبلية:

- أنظمة التحكم الذكية

- تصاميم موفرة للطاقة

- آلات مدمجة متعددة الوظائف

- التكامل مع خطوط التعبئة والتغليف

الأسئلة الشائعة حول ماكينة صنع الكريب

هي ماكينة صنع الكريب سهلة التشغيل?

نعم, تم تصميم معظم الآلات للتشغيل البسيط مع الحد الأدنى من التدريب.

هل يمكن لآلة واحدة إنتاج أنواع مختلفة من الكريب؟?

نعم, عن طريق ضبط وصفات وإعدادات الخليط.

هي آلة صنع الكريب الأوتوماتيكية مناسبة للشركات الصغيرة?

قطعاً. تعتبر العديد من النماذج الأوتوماتيكية المدمجة مثالية للشركات الناشئة.

لماذا تستثمر في ماكينة صنع الكريب?

أ ماكينة صنع الكريب يعد استثمارًا ذكيًا لأي شركة تعمل في إنتاج الكريب. سواء كنت تدير مقهى صغيرًا أو مصنعًا كبيرًا للأغذية, باستخدام أ آلة صنع الكريب التجارية أو الصناعية يساعدك على تحسين الكفاءة, ضمان جودة متسقة, تقليل تكاليف العمالة, وتوسيع نطاق عملك بنجاح.

مع تزايد شعبية الكريب في جميع أنحاء العالم, اختيار الحق ماكينة صنع الكريب الأوتوماتيكية يمكن أن يمنح عملك ميزة تنافسية قوية وربحية طويلة المدى.