مقدمة

الحب العالمي للكريسبي, أدت البطاطس المقلية الذهبية إلى زيادة الطلب المتزايد في المطاعم, سلاسل الوجبات السريعة, والصناعات الغذائية المجمدة. لتلبية هذا الطلب بكفاءة, يتجه العديد من المصنعين ورجال الأعمال إلى خط إنتاج آلة البطاطس المقلية الأوتوماتيكية. يعمل هذا النظام المتكامل تمامًا على تبسيط عملية معالجة البطاطس, يزيد الإنتاجية, ويضمن جودة متسقة.

سوف نستكشف الإعداد الكامل, انهيار التكلفة, و الآلات الرئيسية خط إنتاج البطاطس المقلية الأوتوماتيكي. سواء كنت معالج طعام صغير الحجم أو عملاقًا صناعيًا, تم تصميم هذا الدليل لمساعدتك على اتخاذ قرارات مستنيرة.

لماذا تختار خط إنتاج آلة البطاطس المقلية الأوتوماتيكية?

إن الانتقال من المعالجة اليدوية إلى المعالجة التلقائية يجلب فوائد عديدة:

- كفاءة أعلى: عمليات مبسطة مع المعالجة المستمرة.

- تحسين النظافة: معدات الفولاذ المقاوم للصدأ تلبي معايير الجودة الغذائية.

- توفير العمالة: يقلل من احتياجات القوى العاملة بنسبة تصل إلى 70%.

- جودة متسقة: قطع موحد, القلي, والتعبئة.

- قابلية التوسع: مناسبة للصغار, واسطة, وعمليات كبيرة.

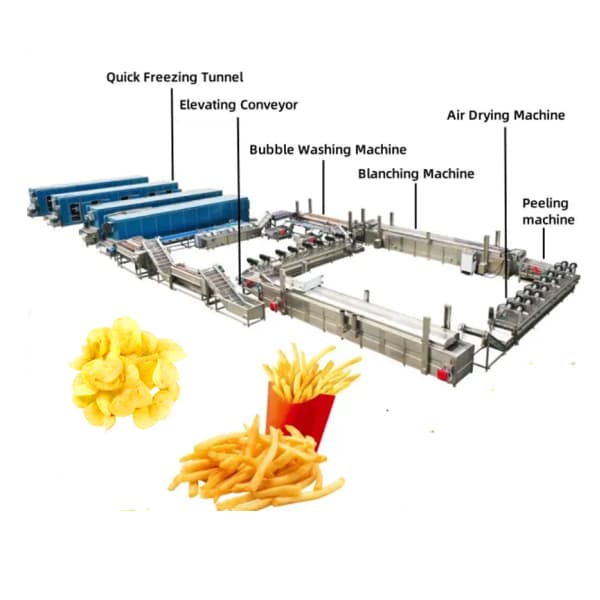

الآلات الأساسية في خط إنتاج البطاطس المقلية

تلعب كل آلة في خط الإنتاج دورًا محددًا. فيما يلي تفصيل تفصيلي للمكونات الأساسية:

1. ماكينة غسل وتقشير البطاطس

- وظيفة: ينظف ويقشر البطاطس النيئة.

- سعة: 300 كجم/ساعة إلى 2000 كجم/ساعة

- مادة: الفولاذ المقاوم للصدأ من الفولاذ المقاوم للصدأ

2. ماكينة تقطيع البطاطس المقلية

- وظيفة: تقطع البطاطس إلى أعواد موحدة.

- حجم القطع قابل للتعديل: تشمل الأحجام الشائعة 7 × 7 مم, 9x9mm, و10x10 ملم.

- خيارات الشفرة: مستقيم, تغضن, أو تكوينات شفرة الموجة.

3. آلة الشطف/الفقاعة

- وظيفة: يزيل النشا السطحي من قطع البطاطس المقلية.

- تكنولوجيا: يستخدم فقاعات الهواء ذات الضغط العالي وبخاخات الماء.

4. آلة التخلص

- وظيفة: يعطل الانزيمات, يحافظ على اللون والملمس.

- نطاق درجة الحرارة: 70-90 درجة مئوية

- النطاق الزمني: 1– 3 دقائق حسب حجم الزريعة

5. آلة نزح المياه

- وظيفة: يزيل الرطوبة الزائدة بعد السلق.

- يكتب: نظام الطرد المركزي للتجفيف السريع

6. آلة القلي المستمرة

- وظيفة: تقلى أصابع البطاطس إلى الكمال الذهبي.

- خيارات التدفئة: كهربائي, الغاز, أو الديزل

- التحكم في درجة الحرارة: قابل للتعديل بين 150-180 درجة مئوية

7. آلة إزالة الزيوت

- وظيفة: يقلل من محتوى الزيت للحصول على بطاطس مقلية أكثر صحة.

- يكتب: سبينر الطرد المركزي

8. آلة التجميد (فريزر IQF)

- وظيفة: يجمد البطاطس المقلية بسرعة للحفاظ على الملمس والطعم.

- درجة حرارة: -18 درجة مئوية أو أقل

9. ماكينة وزن وتغليف

- وظيفة: يملأ تلقائيا, يزن, الأختام, وحزم التسميات.

- أنواع التغليف: عبوات فراغ, أكياس الوسائد, أو التعبئة والتغليف السائبة

سير العمل الكامل لخط الإنتاج

- تحميل البطاطس: تُسكب البطاطس النيئة في قادوس.

- الغسيل والتقشير: تتم إزالة الأوساخ والجلد.

- قطع: يتم تقطيع البطاطس المنظفة إلى شرائح متساوية.

- الغسيل مرة أخرى: يشطف النشا.

- السلق: يحافظ على لون البطاطس الطبيعي.

- نزح المياه: تحضير البطاطس المقلية للقلي.

- القلي: يطبخ البطاطس المقلية بالدرجة المرغوبة.

- إزالة الزيوت: يقلل الزيت ويحسن مدة الصلاحية.

- التجميد (خياري): للبطاطس المقلية المجمدة.

- التغليف: يتم وزن البطاطس المقلية وإغلاقها في أكياس.

جدول المواصفات الفنية

| آلة | قوة (كيلوواط) | سعة (كجم/ساعة) | أبعاد (مم) |

|---|---|---|---|

| غسل & آلة التقشير | 1.5 - 3.0 | 300 - 2000 | 1200x850x800 |

| آلة القطع | 1.1 - 2.2 | 300 - 2000 | 950x800x1000 |

| غسالة الفقاعات | 2.2 - 4.0 | 300 - 2000 | 1800×1000x1200 |

| آلة التخلص | 6.0 - 12 | 300 - 2000 | 2200x800x1400 |

| آلة نزح المياه | 1.5 | 300 - 1000 | 900x600x900 |

| آلة القلي | 30 - 120 | 300 - 2000 | 5000x1200x1800 |

| آلة إزالة الزيوت | 1.5 | 300 - 1000 | 1000x800x1000 |

| فريزر IQF | 15 - 80 | 300 - 2000 | قابلة للتخصيص |

| آلة التغليف | 2.0 - 5.0 | 300 - 2000 | 1500x800x1700 |

تقسيم التكلفة: ماذا تتوقع

يختلف الاستثمار في خط إنتاج البطاطس المقلية الأوتوماتيكي بناءً على:

- سعة

- مستوى الأتمتة

- جودة المواد

- التجميد & خيارات التعبئة والتغليف

نطاقات التكلفة المقدرة:

| القدرة الإنتاجية | يكتب | التكلفة المقدرة (دولار أمريكي) |

| 100 - 300 كجم/ساعة | خط نصف آلي | $10,000 - $30,000 |

| 500 - 1000 كجم/ساعة | أوتوماتيكية بالكامل متوسطة الحجم | $40,000 - $90,000 |

| 1000 - 2000+ كجم/ساعة | خط النطاق الصناعي | $100,000 - $300,000+ |

قد تشمل التكاليف الإضافية:

- إعداد وتركيب المصنع

- رسوم الشحن والجمارك

- أدوات الصيانة وقطع الغيار

- تدريب الموظفين

متطلبات إعداد المصنع

متطلبات المساحة:

- خط صغير (300 كجم/ساعة): 100 - 150 م²

- خط كبير (2000 كجم/ساعة): 500 - 800 م²

المرافق:

- كهرباء: 30 - 150 كيلوواط اعتمادا على الإعداد

- ماء: 3 - 10 م³/ساعة

- زيت للمقلاة: التعبئة الأولية ل 200 - 500 لتر

القوى العاملة:

- مطلوب مشغلين: 3 - 6 (للخط التلقائي بالكامل)

- وقت التدريب: 3 - 5 أيام مع دعم الموردين

الربحية وعائد الاستثمار

دعونا نفكر في إنتاج مصنع متوسط الحجم 1000 كجم/ساعة:

- الإخراج اليومي: ~ 8000 كجم (8 ساعات)

- سعر الجملة: $1.2 - $2.0 لكل كجم (يختلف حسب المنطقة)

- الإيرادات اليومية: ~ 9600 دولار (متوسط. $1.2/كجم)

- الإيرادات الشهرية: ~ 200000 دولار +

العائد على الاستثمار: عادة ما يتم استرداد الاستثمار في 6 ل 18 أشهر حسب ظروف السوق المحلية.

اختيار المورد المناسب

ابحث عن مورد مع:

- شهادة CE/ISO

- خدمات التثبيت المحلية

- توفر قطع الغيار

- التدريب والدعم الفني

أفضل مثال للموردين: DT Food Machine Co., المحدودة. تقدم حلولاً متكاملة, تصاميم مخصصة, والصادرات إلى أكثر من 60 بلدان.

الأسئلة الشائعة

س 1: هل يمكنني تخصيص حجم وشكل البطاطس المقلية؟?

نعم, تدعم الآلات شفرات القطع المتعددة للقطع المستقيم, تغضن, أو بطاطا مقلية.

Q2: هل هذا الخط مناسب للبطاطس المقلية الطازجة والمجمدة؟?

نعم. وذلك بإضافة الفريزر والتغليف النتروجيني, يمكن للخط إنتاج البطاطس المقلية المجمدة.

س 3: ماذا لو كنت أرغب في توسيع الإنتاج لاحقًا?

هذه الخطوط وحدات وقابلة للتطوير. يمكن إضافة آلات إضافية أو وحدات ذات سعة أكبر.

س 4: كم من الوقت يستغرق تركيب الخط بأكمله?

يستغرق التثبيت والاختبار عادة 7 - 15 أيام اعتمادا على التعقيد.

س 5: كيف أحافظ على المعدات?

التنظيف المنتظم, التفتيش الشهري, وعادة ما يكون استبدال الأجزاء سنويًا كافيًا.

خاتمة

الاستثمار في ان خط إنتاج آلة البطاطس المقلية الأوتوماتيكية و خط إنتاج البطاطس المقلية على نطاق صغير يقدم كفاءة لا مثيل لها, تناسق, وإمكانات الربح. سواء كنت تتطلع إلى إطلاق علامة تجارية للبطاطس المجمدة أو توريد سلاسل الوجبات السريعة, يضمن الخط الآلي أن منتجك يلبي أعلى المعايير.

مع تكوينات قابلة للتطوير, أداء موثوق, وعائد استثمار مرتفع, يعد خط الإنتاج هذا خطوة إستراتيجية لأي رجل أعمال أو مستثمر في مجال تصنيع الأغذية.